Joseph James

Senior Member

This may help someone else. In a nutshell-count the turns. If you use a slightly larger wire wire you can use less turns.

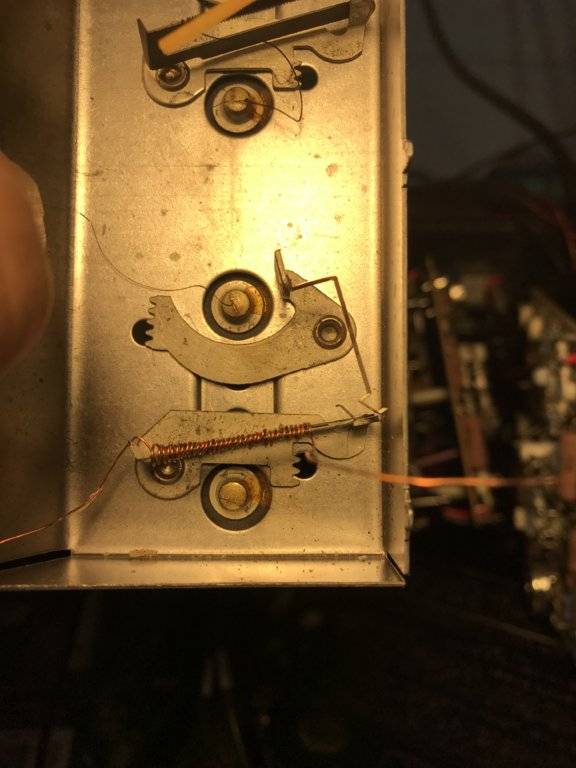

This is the old coil that was burned out from a garage changing my battery cable and leaving it loose.

The needle is held on by two bends-one from the coil form and one from a stationary piece. It is easier to rewind the coil with the needle off plus it is very delicate.

Completed winding. I salvaged wire from an old horizontal drive transformer on an old tv chassis. I used enamel wire. You need a match or lighter to burn the enamel at the ends of the wire or you will have no conductivity.

This isn’t hard to do and is cheaper than buying a set of gauges if you can even find any.

This is the old coil that was burned out from a garage changing my battery cable and leaving it loose.

The needle is held on by two bends-one from the coil form and one from a stationary piece. It is easier to rewind the coil with the needle off plus it is very delicate.

Completed winding. I salvaged wire from an old horizontal drive transformer on an old tv chassis. I used enamel wire. You need a match or lighter to burn the enamel at the ends of the wire or you will have no conductivity.

This isn’t hard to do and is cheaper than buying a set of gauges if you can even find any.