Jack-Stand

Member

Hello All, I've used this forum a lot, but it's taken me a while to finally join. I recently decided I'd go after one of the cheaper items on my Mopar (or so I thought), and I decided that I'd give casting my tail lenses a try. I don't have many pictures of the process as a whole, but I'll try to upload more pictures tonight and/or tomorrow.

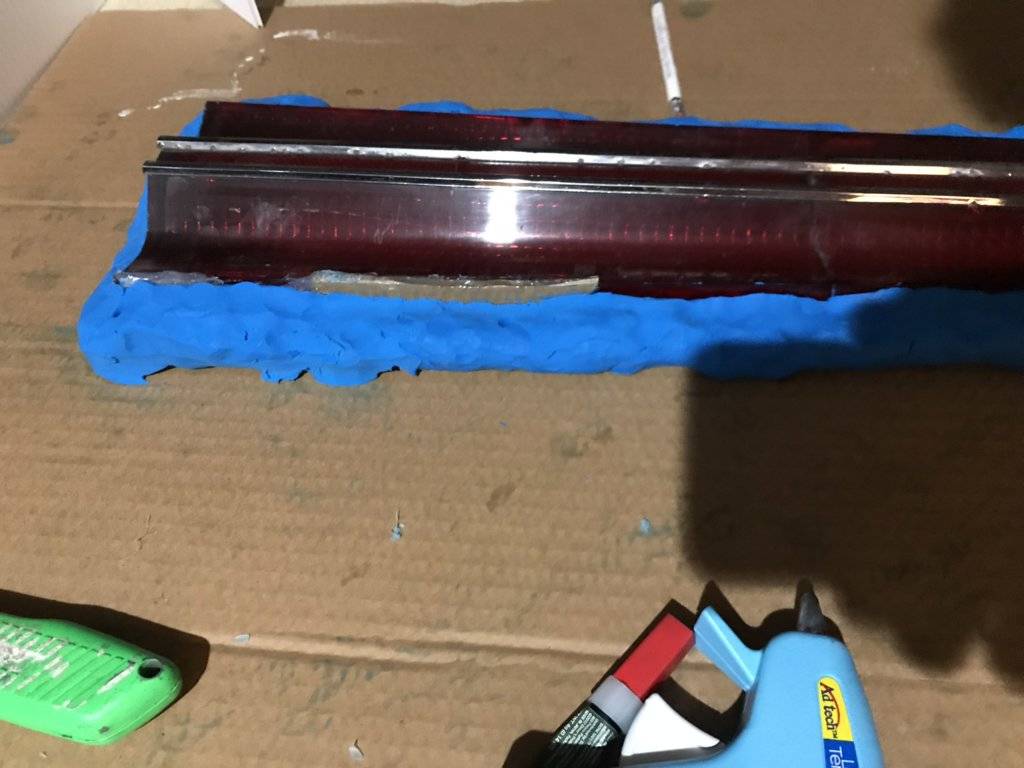

The first lens I tried to cast was the driver side inner lens. Unfortunately my lens was damaged pretty bad, so I had to use cardboard and hot glue to effectively create the bulk material that I'll later shave down. From there, I clayed the light in, and built my mold dam around the outside. Then I was ready for my first silicone rubber pour. After that, I removed the clay from the bottom of the mold, and I got ready to pour the other half of my 2 piece mold. (One thing to note here, because I seriously screwed it up, the mold release I bought through alumilite didn't have enough separation for the rubber I was using. That being said, the sorry thing fused together, and I got to cut my first mold open.) I'm now using petroleum jelly along with the mold release for my other molds and I'm getting much better success.

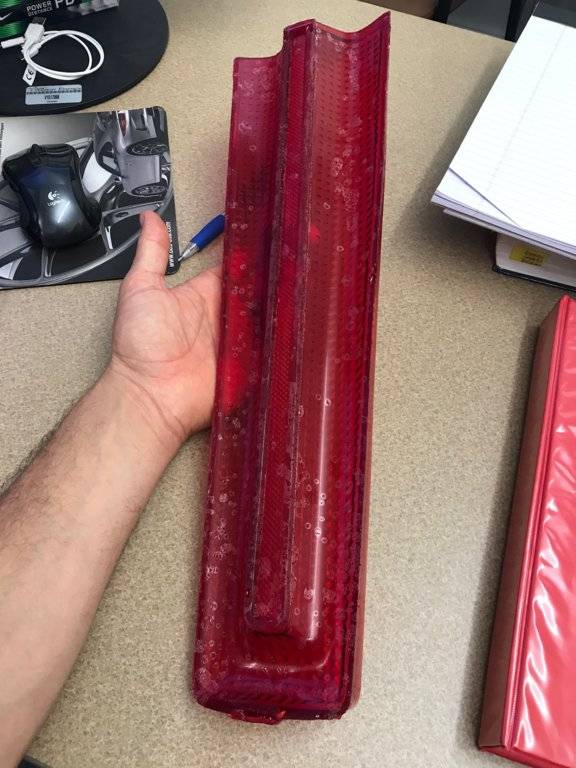

The outer lens attached to this thread is the driver's side outer lens, and basically what happened is that a bubble got caught in the mold and couldn't escape. I drilled some air vent holes into the mold, and I finally got a good cast part.

I've now successfully cast both of my inner lenses, and my driver's side outer lens. The picture of the inner lens attached to this thread was my most recent success, which was my passenger side inner lens. There were a couple of minor blemish bubbles in the finish, and I still need to cut off the flashing and polish the lens, but overall I'm pretty pleased with the end result.

The first lens I tried to cast was the driver side inner lens. Unfortunately my lens was damaged pretty bad, so I had to use cardboard and hot glue to effectively create the bulk material that I'll later shave down. From there, I clayed the light in, and built my mold dam around the outside. Then I was ready for my first silicone rubber pour. After that, I removed the clay from the bottom of the mold, and I got ready to pour the other half of my 2 piece mold. (One thing to note here, because I seriously screwed it up, the mold release I bought through alumilite didn't have enough separation for the rubber I was using. That being said, the sorry thing fused together, and I got to cut my first mold open.) I'm now using petroleum jelly along with the mold release for my other molds and I'm getting much better success.

The outer lens attached to this thread is the driver's side outer lens, and basically what happened is that a bubble got caught in the mold and couldn't escape. I drilled some air vent holes into the mold, and I finally got a good cast part.

I've now successfully cast both of my inner lenses, and my driver's side outer lens. The picture of the inner lens attached to this thread was my most recent success, which was my passenger side inner lens. There were a couple of minor blemish bubbles in the finish, and I still need to cut off the flashing and polish the lens, but overall I'm pretty pleased with the end result.