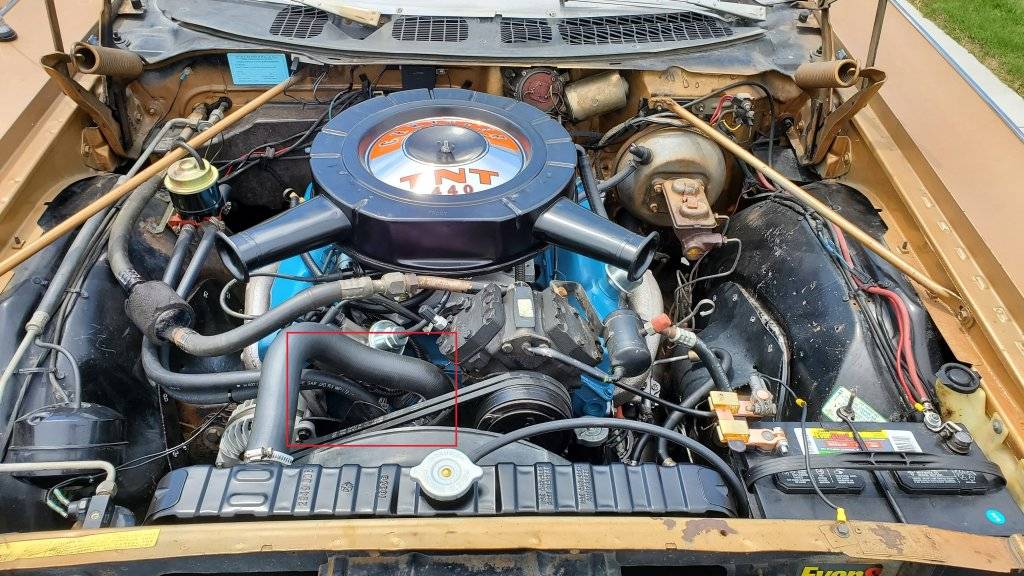

1969 Chrysler 440/505, everything is new, overhauled or rebuilt. I've put about 2000 miles on the car since May and now the rad/heater hoses are starting to seep/drip.

1. Noticed a few drips on the lower radiator hose coming from the water pump side. Tightened screw type band clamp, worked for about a week, clamp loose again.

2. Heater hose nipple fittings seeping, 1/2" and 5/8". These were fresh install in May. What type sealant and/or thread tape are you using?

At initial rebuild I tried using the squeeze type clamps that require pliers to install. They ended up leaking. Tore everything apart and installed screw type steel band clamps, but they are now working their way loose. Is there a Mopar Kit with correct size clamps?

Additionally, Ive seen some cars with the 5/8" nipple fitting about 6"-8" tall. Where do I get one of those? P/N # ?

Because the heater hose clamps are buried, every little leak requires a semi-big tear down to get in there and work on them. I just want to fix this correctly and be done. Thx

1. Noticed a few drips on the lower radiator hose coming from the water pump side. Tightened screw type band clamp, worked for about a week, clamp loose again.

2. Heater hose nipple fittings seeping, 1/2" and 5/8". These were fresh install in May. What type sealant and/or thread tape are you using?

At initial rebuild I tried using the squeeze type clamps that require pliers to install. They ended up leaking. Tore everything apart and installed screw type steel band clamps, but they are now working their way loose. Is there a Mopar Kit with correct size clamps?

Additionally, Ive seen some cars with the 5/8" nipple fitting about 6"-8" tall. Where do I get one of those? P/N # ?

Because the heater hose clamps are buried, every little leak requires a semi-big tear down to get in there and work on them. I just want to fix this correctly and be done. Thx