If you want the exact revs/mile for the various tire sizes, you can check out ALL of the AMA Specification documents for the various cars in the Library(?) area of

www.hamtramck-historical.com. The 45mph spec is usually the one the tires companies use. THEN you can go into

www.tirerack.com and look for various tire sizes, which will have THEIR revs/mile specs.

I appreciate that most trans shops use the tire's height and rear axle ratio to decide which gears to use, but that can be problematic as the tire's rolling diameter can change with inflation pressure. Even with radials, which have the belt and aren't supposed to chang

The '66 Chrysler/Imperial FSM lists the various gear combinations (drive gear on the trans output shaft and the driven gear, which runs the speedo cable) and tire sizes (usually 8.25x14 for a base Newport to 8.85x14 for a Town & Country wagon). All laid out, as the factory intended.

Using that with the SAE Specs tire information, you can then determine which modern size tire will work with which orig gear/axle ratio/tire size combination.

In one of the old "Hot Rod Annuals", from about '1963, there was a formula to determine mph/1000rpm using a direct measurement for tire circumference. It involved chalk-marking the tread, rolling the vehicle until the chalk mark was directly under the centerline of the wheel (at 6 o'clock location), then measuring the length between the two chalk marks on the pavement. Which was considered to be the "rolling circumference", which could be different than measuring the tire's circumference mounted on the wheel, but the tire/wheel not on the car, fully-inflated. From that, a "rolling radius" could be computed, for the particular tire size. Which was then put into the formula to determine mph/1000rpm. Using road test data, I could work backward to get the rolling radius number.

Some claimed that method of determining the rolling radius was imperfect as the tire's tread would go from being compressed (due to the car's load) to being "free" when it wasn't touching the pavement.

The end result is that 1.0 mile takes a certain number of speedometer cable revolutions. From a particular reference tire size, as the revs/mile decreases (slows down), the gear ratio would need to increase to maintain the same distance reading. If the axle ratio number goes up, for the particular tire size, the cable would need to slow down, too.

THE reason I'm mentioning ONLY distance is that that's the ONE function of the speedometer that is directly-geared. Get the distance calibration done FIRST, then worry about the speed aspect of things. If the distance calibration is not close to being correct, the indicated speed will not be within specs.

One thing I liked about the '60s-era Chrysler speedometers was that they had the normal markings at 5mph and 10mph increments, but ALSO at 1mph increments between the main markings. Rather than just blank space between the 5mph and 10mph increments. Be that as it may.

Several different methods to get similar answers,

Enjoy!

CBODY67

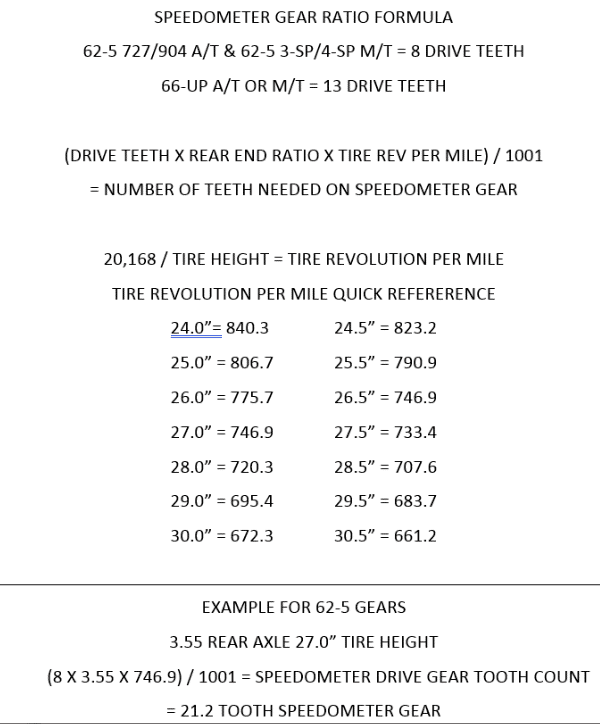

The early transmissions used a much different speedometer gear and they're not interchangeable with the later stuff and while everyone can find a correction calculation chart for the later stuff I recently came across this gem (courtesy Brewer's) that actually works with both as long as you enter the correct data. So I thought I'd put it here so I can find it next time I want it.

The early transmissions used a much different speedometer gear and they're not interchangeable with the later stuff and while everyone can find a correction calculation chart for the later stuff I recently came across this gem (courtesy Brewer's) that actually works with both as long as you enter the correct data. So I thought I'd put it here so I can find it next time I want it.

The early transmissions used a much different speedometer gear and they're not interchangeable with the later stuff and while everyone can find a correction calculation chart for the later stuff I recently came across this gem (courtesy Brewer's) that actually works with both as long as you enter the correct data. So I thought I'd put it here so I can find it next time I want it.

The early transmissions used a much different speedometer gear and they're not interchangeable with the later stuff and while everyone can find a correction calculation chart for the later stuff I recently came across this gem (courtesy Brewer's) that actually works with both as long as you enter the correct data. So I thought I'd put it here so I can find it next time I want it.