View attachment 50692View attachment 50693View attachment 50694View attachment 50695I'm replacing the headliner in the 4DSD after evicting the mice. I have the entire interior removed. This car had all the windlace removed when I bought it.

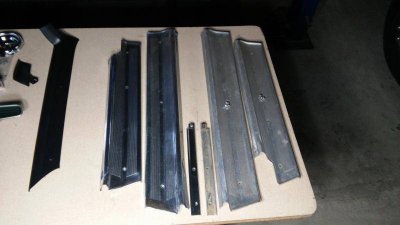

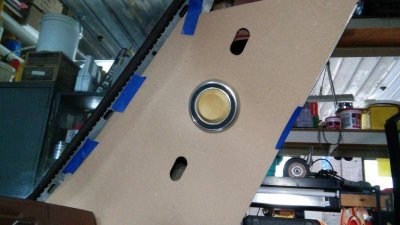

After comparing it with the Custom 4DSD, I realized there are two different kinds of quarter trim.

The Newp has/had windlace all the way down to the rear sill plate. The Custom stops at the beltline.

The Newp has a quarter trim panel similar to a door panel. The custom has a plastic trim panel similar to the cowl kick panels.

First three pics are of the Custom. The rest are of the Newp.

After comparing it with the Custom 4DSD, I realized there are two different kinds of quarter trim.

The Newp has/had windlace all the way down to the rear sill plate. The Custom stops at the beltline.

The Newp has a quarter trim panel similar to a door panel. The custom has a plastic trim panel similar to the cowl kick panels.

First three pics are of the Custom. The rest are of the Newp.