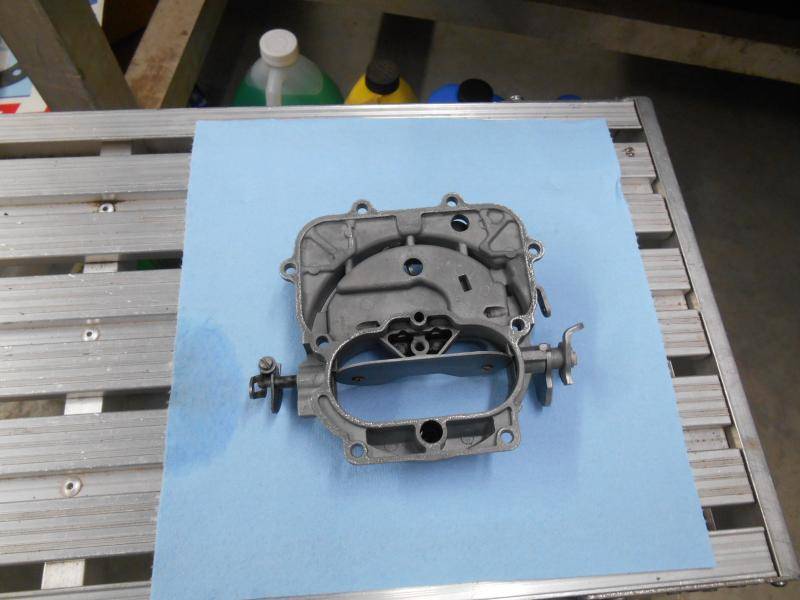

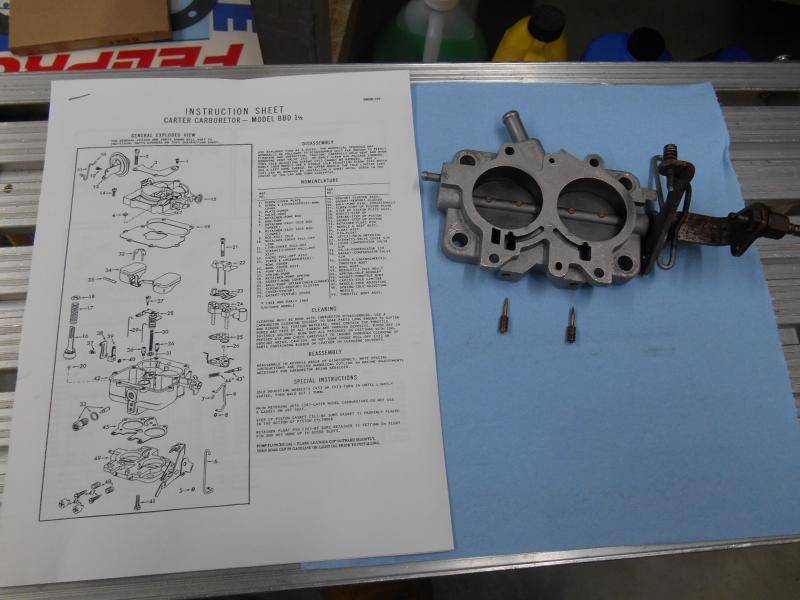

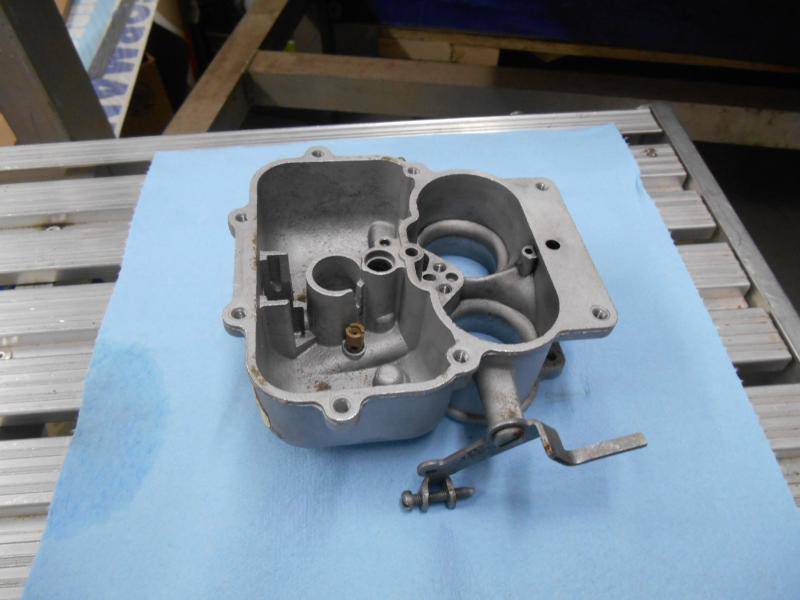

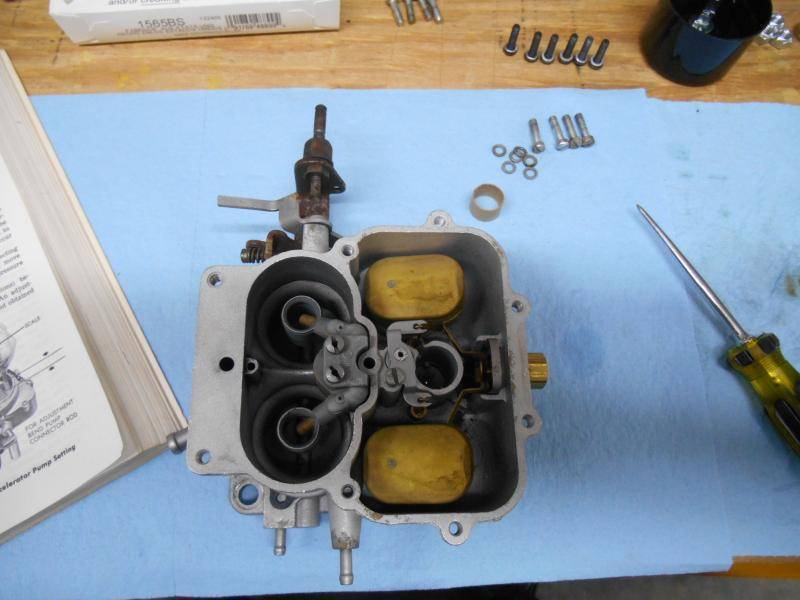

Hey guys, I thought I would post up some photos of my rebuild. We finally got my car running for 15 minutes Friday off a bottle, but it would not stay idling by itself. I found that the carb was barely attached to the manifold due to the studs being too short.It also was filthy. I was lucky to find a refresh kit a parts store 30 miles away, so away I went. It was a Standard 1565B kit. I will put it on the car this afternoon and we will see how much difference this makes.

Last edited: