You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

68 Chrysler turn signal switch replacement with Tilt Telescoping Column

- Thread starter coco

- Start date

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

What he doesn’t mention is how much you have to distort the switches to get them in and out of that deep collar if you don’t have the miller tool to remove it.

Luke Pokrajac

Active Member

Is the Miller tool available? I need to change out the switch on my tilt/telescopic Fury as it doesn't have a detent for left turns anymore.

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

I’ve never seen one but the switch body itself has a 3 5/8” diameter and it needs to be twisted through a 3 1/4” hole. Luckily the switch is pliable enough to do it but the first time I saw it done ( @Clover ) I thought for sure that $250 switch was going to break.

ZOINKS - hadn't heard of the miller tool before...… as if the cost/grief of finding that "unobtanium" switch wasn't enough......

I've done this so many times I can give some clear help here. While the intent of the OP to be helpful by linking that video, that video is not really helpful, as it sets many people who have to go through this job up to damage their column.

The collar with the rolled edge that everyone's trying to force the switch through must come off to do the job properly and without damage hard to replace internal parts. That's the Miller tool that no one has. So, get a 4 leg puller from the tool store - unusual, but not impossible to find like the Miller tool, reverse the arms, use a hose clamp on their other ends to prevent them from "collapsing" away from the rolled edge, and go to work. Use plenty of penetrant down the inside of the collar to allow it to get between the collar and the inside surface the collar is sitting on - it's simply a VERY tight friction fit. Be gentle with the amount of pull you apply with the puller, while gently tapping on the outside of collar to get it to start to slide. Move the 4 leg puller around to apply its force in multiple areas. Again, work GENTLY and slowly, otherwise you will bend that rolled edge.

What the guy in the video also fails to mention is that you have to depress the horn contact ring to allow that big C clip to be removed easily with out wrecking the horn contact ring's molded in ridges that keep it properly aligned. It is held up against the C clip by a majorly strong spring underneath, which needs to be depressed. To do that requires a special tool to do that (also unobtanium), or to make one which is actually fairly simple.

The time it took for that guy to get horn ring out was edited out of the video and glossed over - you can see the damage to the horn contact ring caused by the various tools including a big *** screwdriver. It's lucky he didn't break the horn contact ring.

The collar with the rolled edge that everyone's trying to force the switch through must come off to do the job properly and without damage hard to replace internal parts. That's the Miller tool that no one has. So, get a 4 leg puller from the tool store - unusual, but not impossible to find like the Miller tool, reverse the arms, use a hose clamp on their other ends to prevent them from "collapsing" away from the rolled edge, and go to work. Use plenty of penetrant down the inside of the collar to allow it to get between the collar and the inside surface the collar is sitting on - it's simply a VERY tight friction fit. Be gentle with the amount of pull you apply with the puller, while gently tapping on the outside of collar to get it to start to slide. Move the 4 leg puller around to apply its force in multiple areas. Again, work GENTLY and slowly, otherwise you will bend that rolled edge.

What the guy in the video also fails to mention is that you have to depress the horn contact ring to allow that big C clip to be removed easily with out wrecking the horn contact ring's molded in ridges that keep it properly aligned. It is held up against the C clip by a majorly strong spring underneath, which needs to be depressed. To do that requires a special tool to do that (also unobtanium), or to make one which is actually fairly simple.

The time it took for that guy to get horn ring out was edited out of the video and glossed over - you can see the damage to the horn contact ring caused by the various tools including a big *** screwdriver. It's lucky he didn't break the horn contact ring.

Luke Pokrajac

Active Member

I knew there was a lot more to this job than what the video showed. Thanks for your insight on how to do it right. The shop manual definitely has a much more involved process that what he is letting on to. He's lucky that he didn't break anything...or maybe he did.

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

These switches really are(especially the red ones) flexible and that collar really doesn’t NEED to come off To replace it. It’s probably been done at least 4 or 5 times since I’ve owned the silver car and I witnessed it every time.

Luke Pokrajac

Active Member

Sounds like the switches are known for breaking?... I see the replacement ones through SheeMar...are those the ones that should be purchased.

The switches are known for being hard to find. Unlike the non-tilt Muscle car re-pops that are everywhere.Sounds like the switches are known for breaking?... I see the replacement ones through SheeMar...are those the ones that should be purchased.

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

Yes.Sounds like the switches are known for breaking?... I see the replacement ones through SheeMar...are those the ones that should be purchased.

If it helps, here is the part number for '67 (presumably, also for '68) C-body turn signal switch WITH tilt/telescopic wheel: 2880 271

Of all parts in the '67 book, this is likely the one I have looked up the most. It's one of few switches where the Imperial part is NOT different from other C-body switches.

If you're trying to order one, this part # MAY help. Good luck with the replacement, and if you come across the miller tool, let us know!

Of all parts in the '67 book, this is likely the one I have looked up the most. It's one of few switches where the Imperial part is NOT different from other C-body switches.

If you're trying to order one, this part # MAY help. Good luck with the replacement, and if you come across the miller tool, let us know!

FWIW, the SheeMar replacement does NOT fit 66 TT columns, as they used the GM based cable operated switch that didn't run the wires up through the column, but instead used a cable operated switch that sat at the bottom of the column that the wires connected to with a special Mopar only pigtail that bridged the gap between the Delco switch and the Mopar dash harness.

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

You can buy them new through She-Mar again.If it helps, here is the part number for '67 (presumably, also for '68) C-body turn signal switch WITH tilt/telescopic wheel: 2880 271

Of all parts in the '67 book, this is likely the one I have looked up the most. It's one of few switches where the Imperial part is NOT different from other C-body switches.

If you're trying to order one, this part # MAY help. Good luck with the replacement, and if you come across the miller tool, let us know!

69 300 vert

Well-Known Member

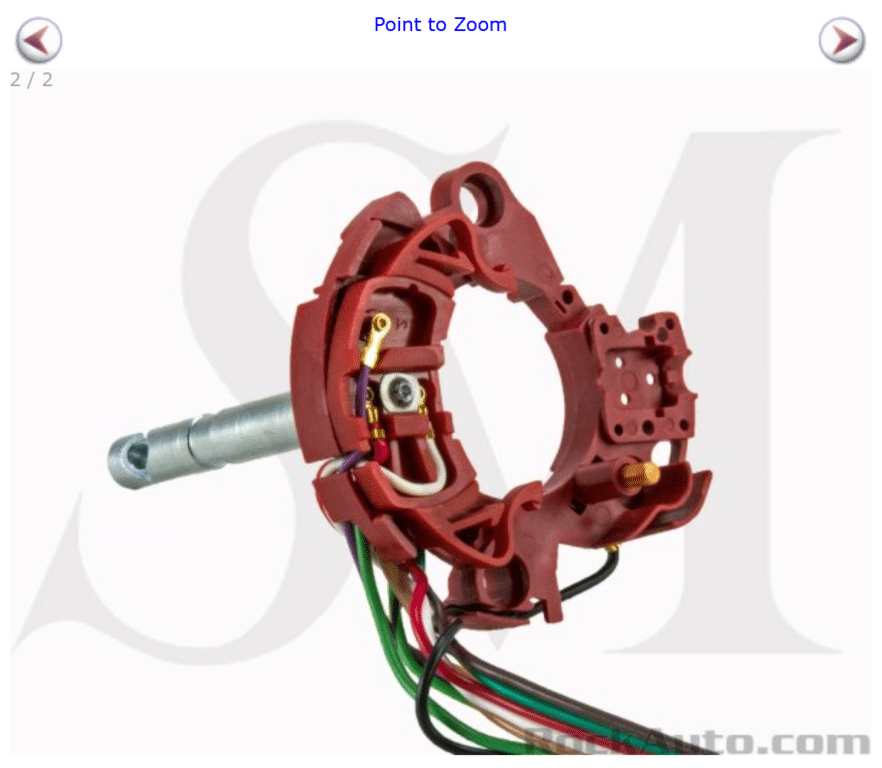

Does anybody have any experience with this switch? It's supposed to be a replacement for 2925506, tilt / telescope, unknown if it works w/ cornering lights.

1968 CHRYSLER 300 7.2L 440cid V8 Turn Signal Switch | RockAuto

1968 CHRYSLER 300 7.2L 440cid V8 Turn Signal Switch | RockAuto

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

That looks like it but they’re cheaper straight fro Shee Mar.Does anybody have any experience with this switch? It's supposed to be a replacement for 2925506, tilt / telescope, unknown if it works w/ cornering lights.

1968 CHRYSLER 300 7.2L 440cid V8 Turn Signal Switch | RockAuto

View attachment 411864

Shee-Mar Inc.: Product List

- Joined

- Nov 14, 2010

- Messages

- 27,944

- Reaction score

- 26,885

Me too. I’d be upset with myself if I didn’t have a spare when I needed it.I've got to pull the trigger on one of these while supplies last.

Forget having a spare! I need a functioning one. I suspect this is a big part of the season I have no lights at all on my vert. This and the headlight switch which will need to be rebuilt.

I consider this part of my ongoing parts search. I want to have a complete car to restore before I tear into it.

I consider this part of my ongoing parts search. I want to have a complete car to restore before I tear into it.

I am in a position where I too may need to replace my turn signal switch. Canceling cam broke last year and now I am chasing an electrical issue with my driver side rear turn signal and brake lights (no tail lights on both sides either). I can find the shee-mar switch on Rock Auto, but looks like shee-mar doesn’t have a website (anymore?). At the prices I can find, I’d like to get the best deal possible.

www.Shee-Mar.com – UNDER CONSTRUCTION!

1968 CHRYSLER 300 7.2L 440cid V8 Turn Signal Switch | RockAuto

www.Shee-Mar.com – UNDER CONSTRUCTION!

1968 CHRYSLER 300 7.2L 440cid V8 Turn Signal Switch | RockAuto