jason99

Well-Known Member

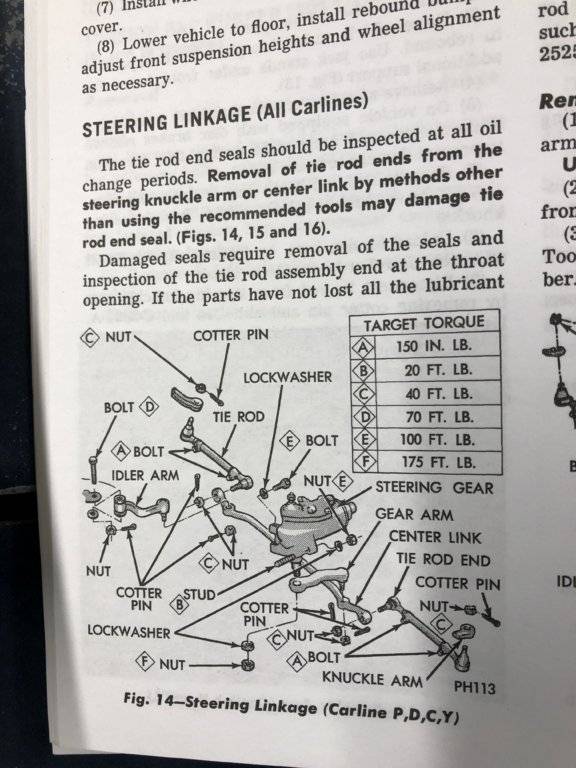

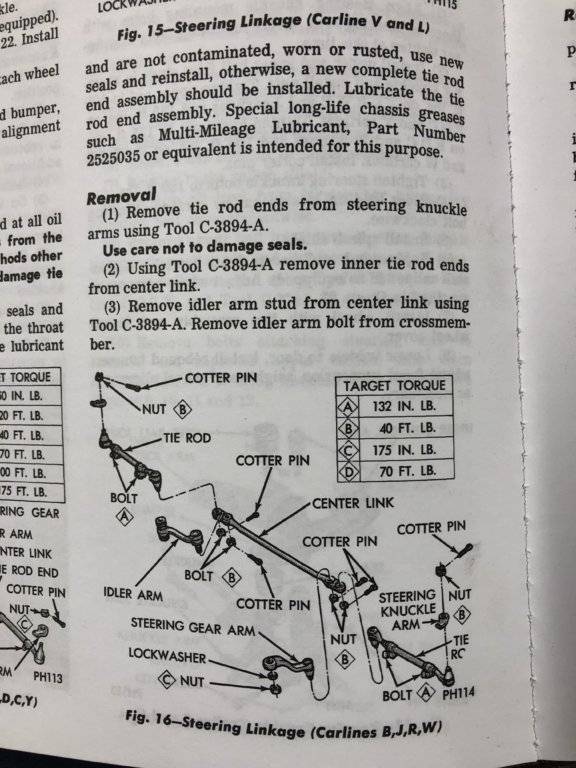

Finally had some time to get the car situation and get ready to address the beat up oil pan I posted about earlier. Going through the FSM for the procedure to remove it, I need to remove the steering linkage. In order to that it indicates I need to remove both tie rod ends and do this with a special tool. Just by looking at it, it seems like if I just took the pin and bolts off of the inner tie rod end, the idler arm, and the stearing arm, I could remove the linkage and get to work.

1) Do I really need to remove the tie rod ends to do this?

2) Is the special tool required?

I'm sure this is obvious to many/most of you, but as evidenced by being guided by reading the service manual, I'm learning these things as I go.

Related, once I have a little time to get my notes together and take a few more measurements and pictures, I'll have a post up about Quick Jack, which has come up a few times in the past in various shop threads.

-Jason

1) Do I really need to remove the tie rod ends to do this?

2) Is the special tool required?

I'm sure this is obvious to many/most of you, but as evidenced by being guided by reading the service manual, I'm learning these things as I go.

Related, once I have a little time to get my notes together and take a few more measurements and pictures, I'll have a post up about Quick Jack, which has come up a few times in the past in various shop threads.

-Jason