1970FuryConv

Old Man with a Hat

Needed: Air conditioning clutch tool. The air conditioning compressor on my 1973 360 has a front bracket, with an indented bolt, where the bolt head is behind the air conditioning clutch. It is impossible, because of the shape of the bracket, to get a wrench or socket on this bolt head without removing the AC clutch. The factory shop manual says to use a spanner wrench while removing the center bolt. The spanner wrench would probably be Y-shaped, with three .25” diameter circular prongs, making an equilateral triangle. Distance center to center 2.375” on each side. I do not have this tool (or kit) and I am wondering where I could buy one. Search on ebay without success. (Miller 4563 is wrong tool, prongs too big)

Note, for anyone who has not worked on these before, the AC clutch is disengaged from the pulley, so tightening belts or pushing down on the belts does absolutely nothing to hold the clutch in position. Center bolt is ½ inch head and I need a way to remove it by holding the clutch stationary.

Thank you in advance for your help.

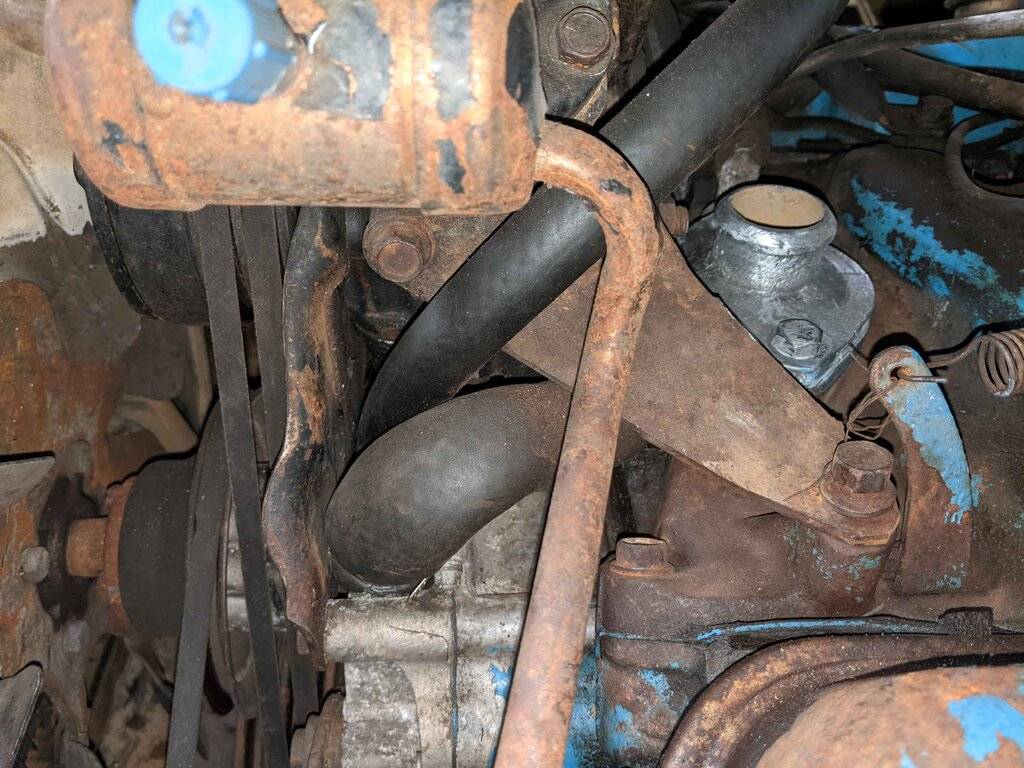

AC Clutch

Bracket (front view)

Bracket (side view)

Miller 4563

Right shape, but prongs too big

Note, for anyone who has not worked on these before, the AC clutch is disengaged from the pulley, so tightening belts or pushing down on the belts does absolutely nothing to hold the clutch in position. Center bolt is ½ inch head and I need a way to remove it by holding the clutch stationary.

Thank you in advance for your help.

AC Clutch

Bracket (front view)

Bracket (side view)

Miller 4563

Right shape, but prongs too big