bluefury361

Old Man with a Hat

If you've never tried to remove anodizing yourself, read up on the process first or leave it to someone who knows.

Do y'all offer a reanodizing service.....? Or know of someplace reputable who does...?

Thanks

Will.

If you've never tried to remove anodizing yourself, read up on the process first or leave it to someone who knows.

I have four FoMoCo and only one Mopar so they barely tolerate me here being a black sheep...:yaayy:

Mopar parts restoration specialist? Well I guess that would leave out my Fords and Mercurys. See, I have four FoMoCo and only one Mopar so they barely tolerate me here being a black sheep...

I've said it before and I'll say it again, nice work Leanna!

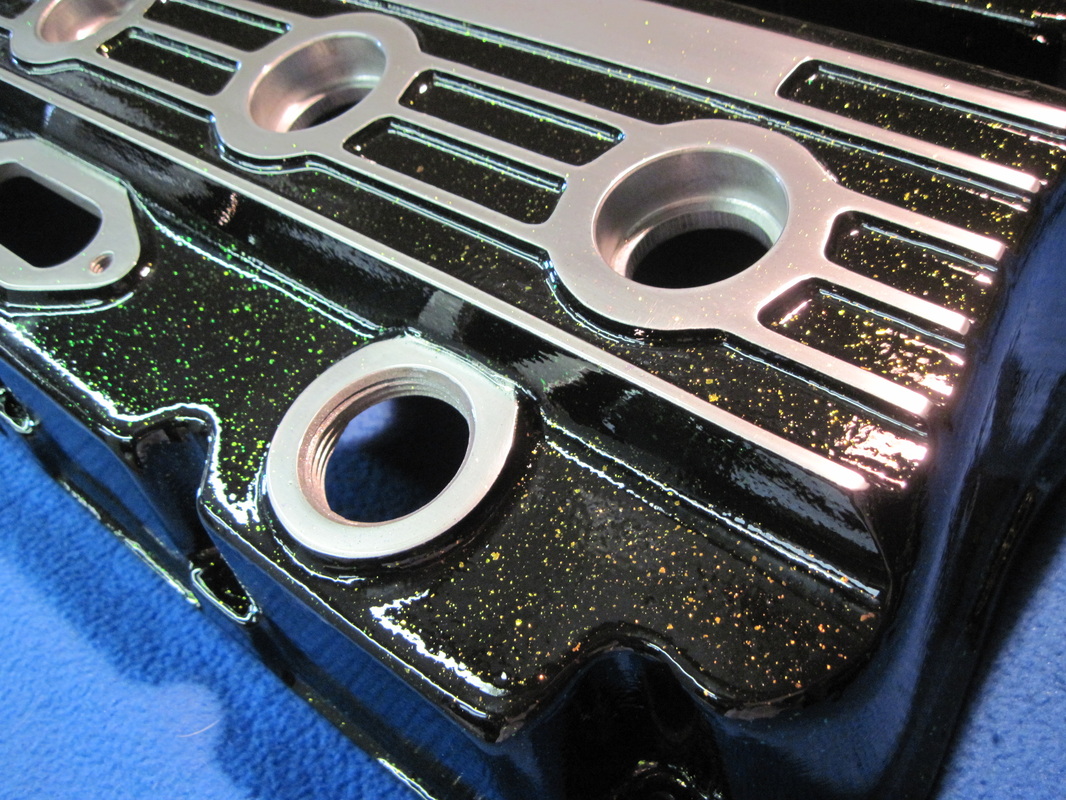

Beautiful work! What is the cost and turn around time for a set of big block valve covers done exactly like these...

View attachment 11984

Usually the factory polishing jobs are just on the bodies, not the fin tops. They often don't even polish inside the bolt recesses much, or at all (I couldn't tell on yours). In between the ribs it's still as-cast and can be customized, but the short ends on MPs are the challenge with the way the ribs end in a very gentle "U" formation. Straight color breaks look goofy so the masking has to be delicate and tidy. Even on these -- some of my best custom work ever (and I'm my own worst critic, believe me) -- you can still see a little itty bitty teeny silver line where the Wetstone Black wrinkle meets the Sea Water Teal.

QUOTE]

I'll have to check a little closer on the detail. The bolt recesses are polished. I don't know about the rest.

I haven't seen such dedication to their craft since....

Actually, it's been ages.

You rock, girl.

< Sent from my tablet >

You got any shrooms Bob?