BillGrissom

Active Member

My original T-bars had sagged so much I was riding on the bump stops. Around 2000, I did a hillbilly fix of adding booster springs around the shock absorbers. Actually, I calculated the extra lift needed, spring rate, and such and selected springs from McMaster-Carr for ~$15. See photo below (wheels hanging). I had to cut and fold the shock surround to make a spring seat. At 2" compression, the springs took 330 lbf off the front end (force at wheels) and increased spring rate from 170 lbf/in at each wheel to 210 lbf/in, so less "boat" feel and better handling. However, if riding on the bumpers the spring rate is much higher. I put a rubber isolator (Ace plumbing part) around the shocks to keep the springs centered. Problems were that I think I got a lot of road noise thru the springs since metal-metal contact (no rubber seats), the springs started wearing into the LCA's a bit, and I would get a thunk when dropping down from speed bumps at work. Thus, don't follow this method unless desperate. On this latest pass, I searched for booster shocks to no avail, since our Newports use real short shocks. If anyone has found some that work, please share. You can buy new T-bars from Firm Feel for only $400/pr, but that would destroy my image.

Since I bought used T-bars from a 440 car for which the seller said the adjusters weren't full in, and I found my strut rod bushings were degraded (ticked me off since I put in a new suspension kit ~1997, PST I recall), I decided to swap T-bars. I was going on hope, since the same PN (660/661, 0.96"D) and once I had them out, I couldn't tell any difference in the clocking. I also had T-bars from a 66 Newport convertible, but same deal. With the new T-bars, I was able to adjust to the factory ride height (A-B = 1.125") and the adjusters were exactly the same left & right. They are pretty far in, with only 3/4" length of threads left, but my LCA's are ~1" off the bumpers (photo), so I could go lower. I am also considering an alum water pump & housing and alum heads down the road, which will help. When I first installed these T-bars, the adjusters were farther out, with one side of the bolt head flush with the bottom of the LCA and the other side sticking out. However, after driving it around a parking lot and over a few speed bumps, I found the LCA's riding on the bumpers and A-B negative (LCA's about horizontal). There must have been some settling, and yes I had bounced the front after each adjustment. I found the LCA nuts tight. I thought I had left them loose, but maybe snugged them after initial setting. I forget, sometimes weeks go by between working on my cars. I had to screw the adjusters in maybe 8 turns to get ride height back. Either the rubber bushings were taking some load, the grease in the sockets squeezed out, or the T-bar metal actually moved (scary thought). Anyway, I'll check them again. I lift the car up before turning the adjusters, to not risk stripping the threads, and grease the threads and tip. They look a little scary w/ so much adjustment, but the bolt heads are only slightly past the bottom of the LCA's, which doesn't look much different than the photos in the shop manual. I don't think the adjusters could jam into the frame rail, a problem some A-body guys have seen.

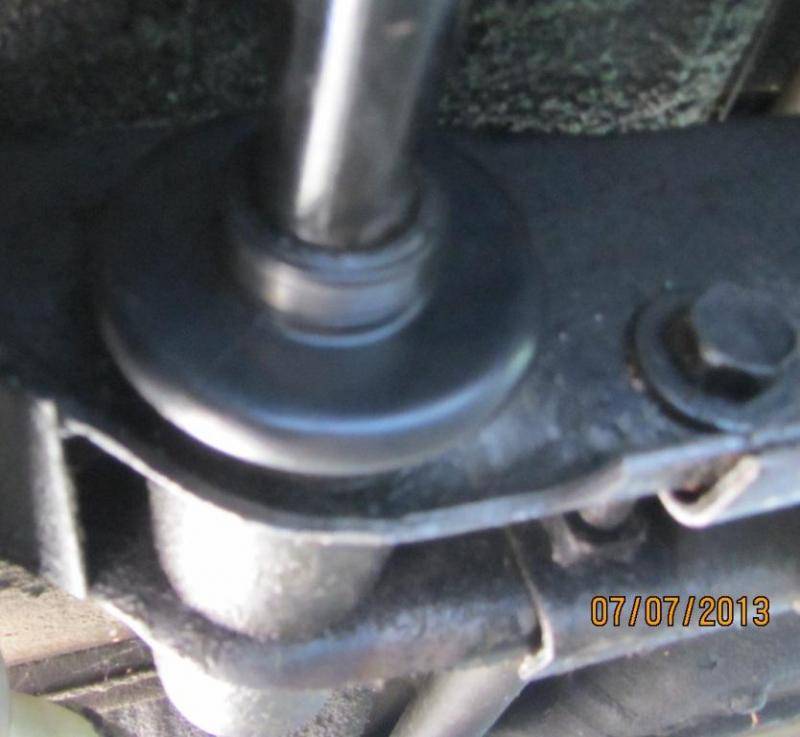

Of interest to some, the rubber grease covers on the rear anchors were bad. One fell apart. Since new ones are $$$, and I pride myself on being the cheapest Mopar bastard, I bought CV joints off ebay and cut the smallest donut off. A pair of Beck-Arnley 1032553 boots for $15 w/ shipping. They fit the Tbar tight w/ the metal clamps (photo) and look almost original. Don't fret over boots too much. These are not sliding joints. The grease is only there to stop corrosion. Indeed, the earliest cars had no grease or boots, which they soon found was not good in the salty north, since they rusted and people lost their front springs while driving. Before this, I fixed my old boots w/ silicone self-fusing tape wrap. I also installed new rubber "sway bar to strut rod" bushings, since cheap (Moog K7064). Mine from the PST kit were OK, so stored them. Of course, I painted everything purty. Not regularly driving the Newport, so I can take my time.

Since I bought used T-bars from a 440 car for which the seller said the adjusters weren't full in, and I found my strut rod bushings were degraded (ticked me off since I put in a new suspension kit ~1997, PST I recall), I decided to swap T-bars. I was going on hope, since the same PN (660/661, 0.96"D) and once I had them out, I couldn't tell any difference in the clocking. I also had T-bars from a 66 Newport convertible, but same deal. With the new T-bars, I was able to adjust to the factory ride height (A-B = 1.125") and the adjusters were exactly the same left & right. They are pretty far in, with only 3/4" length of threads left, but my LCA's are ~1" off the bumpers (photo), so I could go lower. I am also considering an alum water pump & housing and alum heads down the road, which will help. When I first installed these T-bars, the adjusters were farther out, with one side of the bolt head flush with the bottom of the LCA and the other side sticking out. However, after driving it around a parking lot and over a few speed bumps, I found the LCA's riding on the bumpers and A-B negative (LCA's about horizontal). There must have been some settling, and yes I had bounced the front after each adjustment. I found the LCA nuts tight. I thought I had left them loose, but maybe snugged them after initial setting. I forget, sometimes weeks go by between working on my cars. I had to screw the adjusters in maybe 8 turns to get ride height back. Either the rubber bushings were taking some load, the grease in the sockets squeezed out, or the T-bar metal actually moved (scary thought). Anyway, I'll check them again. I lift the car up before turning the adjusters, to not risk stripping the threads, and grease the threads and tip. They look a little scary w/ so much adjustment, but the bolt heads are only slightly past the bottom of the LCA's, which doesn't look much different than the photos in the shop manual. I don't think the adjusters could jam into the frame rail, a problem some A-body guys have seen.

Of interest to some, the rubber grease covers on the rear anchors were bad. One fell apart. Since new ones are $$$, and I pride myself on being the cheapest Mopar bastard, I bought CV joints off ebay and cut the smallest donut off. A pair of Beck-Arnley 1032553 boots for $15 w/ shipping. They fit the Tbar tight w/ the metal clamps (photo) and look almost original. Don't fret over boots too much. These are not sliding joints. The grease is only there to stop corrosion. Indeed, the earliest cars had no grease or boots, which they soon found was not good in the salty north, since they rusted and people lost their front springs while driving. Before this, I fixed my old boots w/ silicone self-fusing tape wrap. I also installed new rubber "sway bar to strut rod" bushings, since cheap (Moog K7064). Mine from the PST kit were OK, so stored them. Of course, I painted everything purty. Not regularly driving the Newport, so I can take my time.

Last edited: