Having trouble locating a new or very good user harmonic damper for my 78 440. It has a cast crank and the part number that I found for it was 3839482…. NLA.

Will the newer fluid filled dampers work the same? Does anyone have experience with them in this or a similar application.

I remember as a kid, there was an old man selling a wheel “Balancer” at the local

Glee market. This Balancer consisted of some ball bearings in a circular tube around a flat metal disc that mounted conventionally between the wheel and hub (much like a brake dust disk). I was the volunteer tester for the guy and he had me un-mount the wheel from a hub to which he had attached to an electric motor with speed control. He removed the balancer and spun it on his finger and it sounded for all the world like my sister’s hola hoop. He spun up the remounted wheel he had me bolt back on and and spun the wheel to show it was way out of balance even at slow speed. Off came the wheel and on went the balancer and …. Absolutely no vibration. From the get go… at any speed he set it.

It left a dent in my memory.

Thoughts on the fluid filled damper please???

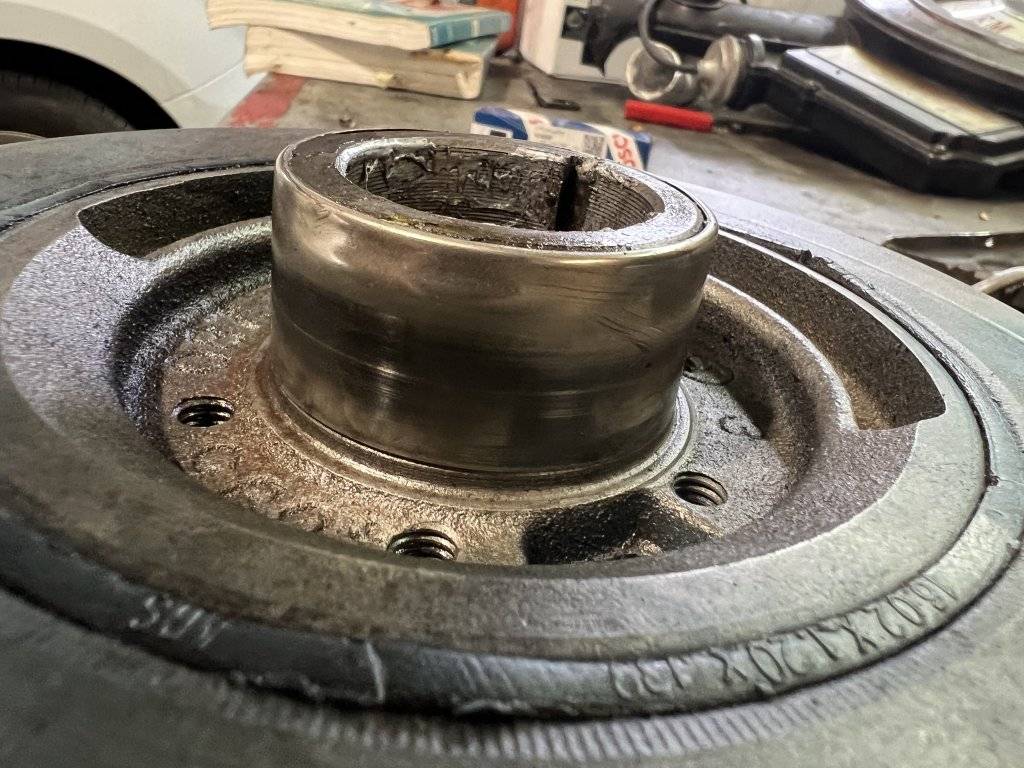

The reason I pulled it was due to a leak in the cover seal. This one looks to have slipped a bit from pictures I found of the same damper. Damper seal surface was also bent/deformed.

Will the newer fluid filled dampers work the same? Does anyone have experience with them in this or a similar application.

I remember as a kid, there was an old man selling a wheel “Balancer” at the local

Glee market. This Balancer consisted of some ball bearings in a circular tube around a flat metal disc that mounted conventionally between the wheel and hub (much like a brake dust disk). I was the volunteer tester for the guy and he had me un-mount the wheel from a hub to which he had attached to an electric motor with speed control. He removed the balancer and spun it on his finger and it sounded for all the world like my sister’s hola hoop. He spun up the remounted wheel he had me bolt back on and and spun the wheel to show it was way out of balance even at slow speed. Off came the wheel and on went the balancer and …. Absolutely no vibration. From the get go… at any speed he set it.

It left a dent in my memory.

Thoughts on the fluid filled damper please???

The reason I pulled it was due to a leak in the cover seal. This one looks to have slipped a bit from pictures I found of the same damper. Damper seal surface was also bent/deformed.