Dylan Galvin

Active Member

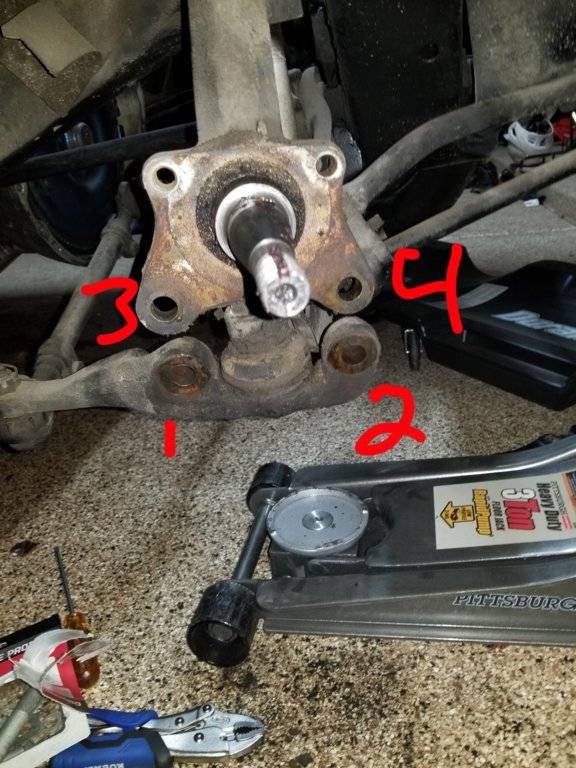

How do I get holes 1 and 2 back up behind holes 3 and 4? Should I just jack up that arm? I cant simply lift it up with my hands.

What?sometimes spellcheck isnt your friend......

Heh woopsInstalling Dick Brake Caliper Bracket

Lol oops, how did i miss your posting?You have a drum brake spindle and a lower ball joint in the picture. Are you doing aftermarket Disc brake conversion? You will need the brake backing plate to go on at the same time.

Where are the disc brake parts mentioned in the title?

Yes, I'm doing an aftermarket conversion. I have a willwood kit made specifically for the drum brake spindle, and the caliper mounting brack holds the whole mess together in my picture up there.You have a drum brake spindle and a lower ball joint in the picture. Are you doing aftermarket Disc brake conversion? You will need the brake backing plate to go on at the same time.

Where are the disc brake parts mentioned in the title?

"TRY NOT TO DIE".

Hey so I'm out working on it now. I can jack it up so it compresses a small amount but then it just lift the whole car up and doesn't seem to make any progress. Does it sound like I'm jacking in the wrong spot, or should I just keep going?^This^

I think that it needs to be mentioned that you got kinda lucky. I probably should have said that in my post

Without any support under the lower control arm, it's being pushed down by the force of the torsion bar. The same force that holds the car up. What is holding it from dropping down farther looks like the sway bar and the front strut. They can take a lot, but really not meant to limit the downward motion and force.

So, as @traintech and I are saying, be sure to place that jack under the lower arm on the other side before you unbolt the lower ball joint. Coil springs are more dangerous, but torsion bars have the same kind of stored energy that is waiting to do you some damage. Not trying to be overcritical, just trying to keep you safe.

Edit: just looked at your profile and kudos to you for being 14 and tackling this project. Being on the planet for 50 years more gives us experience doing this work and living through our mistakes (LOL), it's natural for us to know where you have to put the jack... etc.

Get the jack as far out on the arm as you can. As said, watch out that you don't break the grease fitting.Hey so I'm out working on it now. I can jack it up so it compresses a small amount but then it just lift the whole car up and doesn't seem to make any progress. Does it sound like I'm jacking in the wrong spot, or should I just keep going?