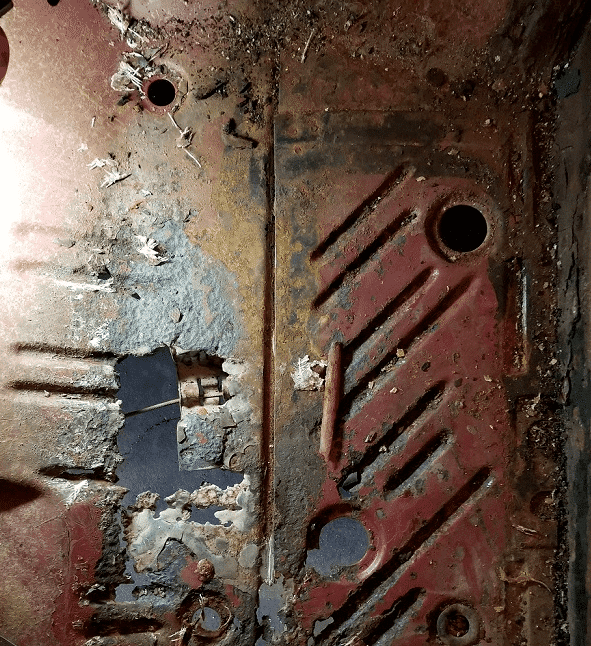

I knew there was a hole in the rear driver floorboard as some prior owner fiberglassed a patch in...however after removing the patch to see how bad, this is what it looks like:

I am not confident of building a patch that includes correctly positioning the parking brake cable bracket. Think i need to find a shop to fix this...anyone had a similar experience and how much did it cost?

Thanks,

Dave

I am not confident of building a patch that includes correctly positioning the parking brake cable bracket. Think i need to find a shop to fix this...anyone had a similar experience and how much did it cost?

Thanks,

Dave