rexus31

Senior Member

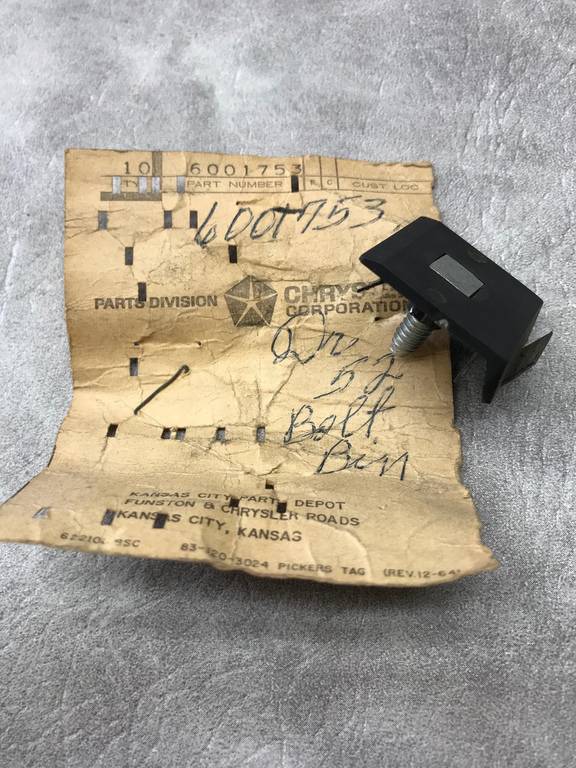

Okay, I dug the clips out. Here's the NOS threaded beltline molding clip p/n 6001753

I also had a few of these threaded clips which secure the deck lid trim on '65's incase you want to play around with it. It would probably work for a mold if you cleaned it up a bit.

I'll mail them out to you USPS Priority Mail tomorrow.

I also had a few of these threaded clips which secure the deck lid trim on '65's incase you want to play around with it. It would probably work for a mold if you cleaned it up a bit.

I'll mail them out to you USPS Priority Mail tomorrow.