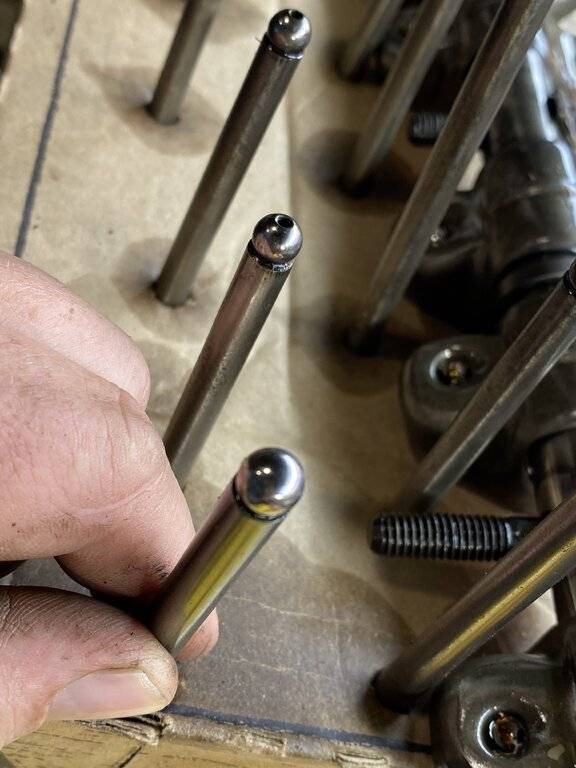

A push rod with no oil hole , needless to say I’m a little bit up set at the engine rebuilder! The engine was rebuilt back in 1999 and I’ve put on at least 150,000 miles since then but WTF .

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Pulled my 383 to replace the rear main seal and found this

- Thread starter Welder guy

- Start date

I pulled the heads to have a look at the Cylinders and pistons. The lifter doesn’t look to bad but I’m replacing them any way now

What abour the rocker arm that pushrod operated? The pushrod doesn't look too bad, or is there something I'm missing? Might just put the correct one in and refresh the gaskets and valve seals/guides/valve job?

150K with no issues? Just pulled the heads for a general inspection?

Oil consumption? Obvious blow-by? Coolant in engine oil?

Just some thoughts,

CBODY67

150K with no issues? Just pulled the heads for a general inspection?

Oil consumption? Obvious blow-by? Coolant in engine oil?

Just some thoughts,

CBODY67

twostick

Senior Member

Not sure what the problem is. Mopars don't oil thru the pushrods.

Kevin

Kevin

69 300 vert

Well-Known Member

I pulled the heads to have a look at the Cylinders and pistons. The lifter doesn’t look to bad but I’m replacing them any way now View attachment 401331 View attachment 401333

Cylinder heads are oiled through the block and rocker shaft.

69 300 vert

Well-Known Member

Cylinder heads are oiled through the block and rocker shaft.

Does seem weird they're not all alike.

It looks to me like there is one correct push rod and 15 wrong ones.

I don't know as the push rods with the oil holes would hurt anything, and 150K miles would prove that point, but it's surprising that they were used.

I don't know as the push rods with the oil holes would hurt anything, and 150K miles would prove that point, but it's surprising that they were used.

mikedrini

Well-Known Member

Also not cool that the builder either didn't notice it OR did notice it and didn't say anything about it. Shady business right there. My builder found 1 piston ring with the wrong gap size out of all of them and made the supplier send a new one out. Meticulous is as meticulous does.

Well the reason I pulled the motor is the rear main seal was leaking badly, front seal leaking and The frost plugs were weeping anti freeze. the transmission front and back was leaking. Just easier to do out side the car. Compression is good and not burning oil . Pulled the heads to do an inspection , cylinder walls look great you can still see the cross hatching. Then I noticed the push rod . The car has Keith black high compression pistons in it , they look good. The car always made a faint knocking noise upon start up like a lifter had collapsed or possible piston slap. Once it warmed up after five minutes the noise went away. I was wondering if this pushrod in combination with the lifter may have made the noise. It’s done well over the last 150 k of mileage , I just thought it strange that it has different pushrods in it. I have a 74 year old mopar mechanic friend guiding me through this. I just wondered what others opinion was on this.

So what I’m gathering from Everybody is I should get myself a new set of pushrods without oil holes in them.It looks to me like there is one correct push rod and 15 wrong ones.

I don't know as the push rods with the oil holes would hurt anything, and 150K miles would prove that point, but it's surprising that they were used.

It doesn't matter if they have holes or not. The rockers oil through the shafts and not through the pushrods like a Magnum or a Chevy engine.So what I’m gathering from Everybody is I should get myself a new set of pushrods without oil holes in them.

I wasn’t sure if there was a problem, I just noticed the pushrods last night while organizing the garage and thought I would ask . My mopar mechanic mentor that’s guiding me through this process Had already Left.Not sure what the problem is. Mopars don't oil thru the pushrods.

Kevin

And very well engineered. Some cams have a grooved bearing surface for constant rocker oiling. How much oil do you need up on top? Maybe not that much.

The lifter doesn’t look to bad but I’m replacing them any way now

If you still have the lifters in proper order and can put them EXACTLY back in the holes them came out of, I recommend you do that and NOT put new lifters on an old camshaft. Those old lifters are working fine and are properly mated to the old cam. New lifters will start a new "break-in" process on the old cam and can lead to a wiping a lobe or two or ten. I'd go with the old pushrods, too. Or replace cam, lifters pushrods, rockers, shafts to ensure no chance of a break-in failure. Mix&match is just not a good strategy with old engines.

The cold knocking you're hearing is piston knock, and that's very common, especially with forged/aftermarket pistons. My engine has all eight slugs rattling for the first minute....I kinda like it. Lets me know everything is nice and loose in there!

oldkimmer

Active Member

If and I say if u wanted pushrod oiling u will have to have lifters that are made for pushrod oiling. Mopar never did that as explained in an earlier post. Not till the small block magnum V8 arrived on the scene. Kim

Are the pushrods all the same length? Maybe the builder was finding different lengths on them? Check it out. Or maybe he used some brand X parts that were close enuf.

I agree with everything above. You don’t seem to have any problems.

I agree with everything above. You don’t seem to have any problems.

Mix&match is just not a good strategy with old engines.

Come to think of it, I'll walk that statement back just a bit. Now is the perfect time to install a new Mellings standard volume/standard pressure oil pump (#M63) and a new timing chain/gear set, as these components only "break in" to themselves. Cheeeep insurance for your next 150K miles.

And good luck with that rear main fix. It's a notorious damn thing and the internet is filled with woeful stories of multiple attempts to stop the leaking on Mopar B/RB engines.

Timing chain and gears are all ready bought, I had a high flow oil pump installed when the engine was done but a new one is not a bad idea

69 300 vert

Well-Known Member

Timing chain and gears are all ready bought, I had a high flow oil pump installed when the engine was done but a new one is not a bad idea

The one on my '68 383 failed ~ 1974 with ~ 80,000 miles. That car came off a tote the note used car lot in 1973, no idea what sort of maintenance it received. I occasionally see NORS Mellings pumps on ePay. I don't see any reason for high flow unless you've done something like fully grooved bearings?

Similar threads

- Replies

- 12

- Views

- 1K

- Replies

- 1

- Views

- 768

- Locked

- Replies

- 23

- Views

- 5K

- Replies

- 2

- Views

- 2K

- Replies

- 20

- Views

- 2K