Eye_on_Fury

New Member

Ok so first off I did do a search and couldn't find anything on this, second this may not be the right place for this question but seems like the right spot.

I'm beginning to lean toward turbos as power adders, don't want to cut a hole in my hood and throttle in a bottle just isn't my schtick. I know very little about them and I'm self teaching myself as much as I can.

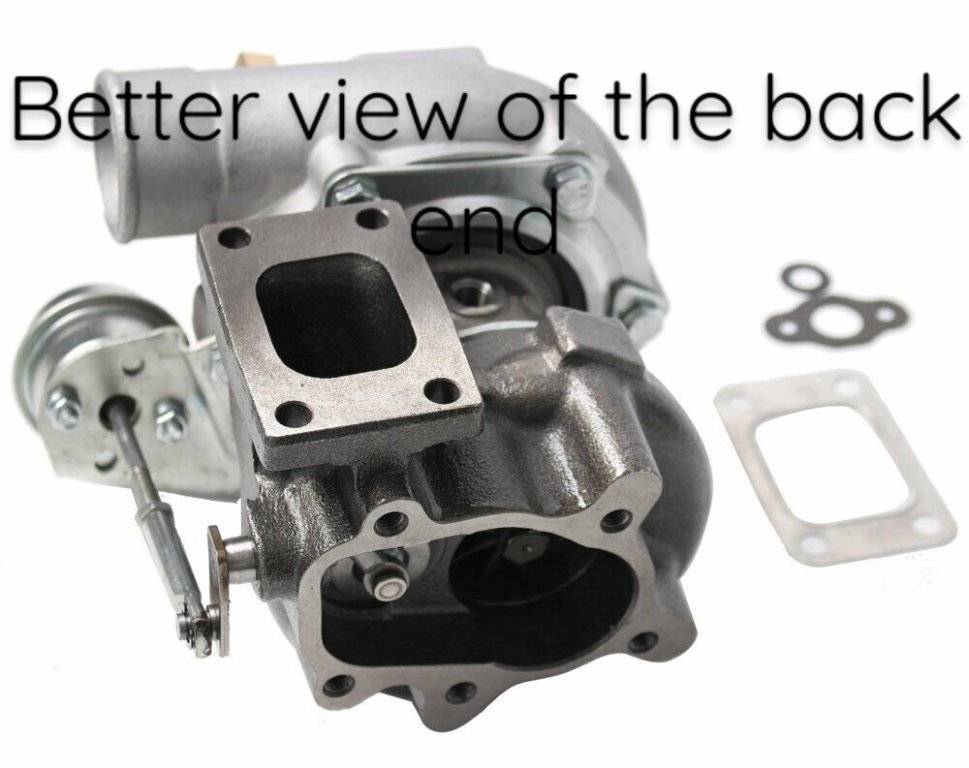

I have come across a feature on water+oil cooled models that I haven't noticed on oil only models and I would like to know what it is and does.

It's a canister that looks like it boost or flow registers and actuates linkage in the down tube end of the housing. Does anyone know what this is and does. I have no intention of buying this model it's just representative. I will be going water+oil so I want to know as much as I can about the components as possible.

This is probably a noob question about Turbochargers, then again I am a noob when it come to turbos so makes sense....

I'm beginning to lean toward turbos as power adders, don't want to cut a hole in my hood and throttle in a bottle just isn't my schtick. I know very little about them and I'm self teaching myself as much as I can.

I have come across a feature on water+oil cooled models that I haven't noticed on oil only models and I would like to know what it is and does.

It's a canister that looks like it boost or flow registers and actuates linkage in the down tube end of the housing. Does anyone know what this is and does. I have no intention of buying this model it's just representative. I will be going water+oil so I want to know as much as I can about the components as possible.

This is probably a noob question about Turbochargers, then again I am a noob when it come to turbos so makes sense....