Goldie I suspect has burnt valves. I am going to confirm this tomorrow. I have never performed any internal work on the engine, except change the timing belt and cam 10 years ago.

I am not looking for anything which will change her drivability. She has a 383, factory 4 barrel, cast exhaust manifold. No plans to change any of those components. Single exhaust but a dual exhaust is planned.

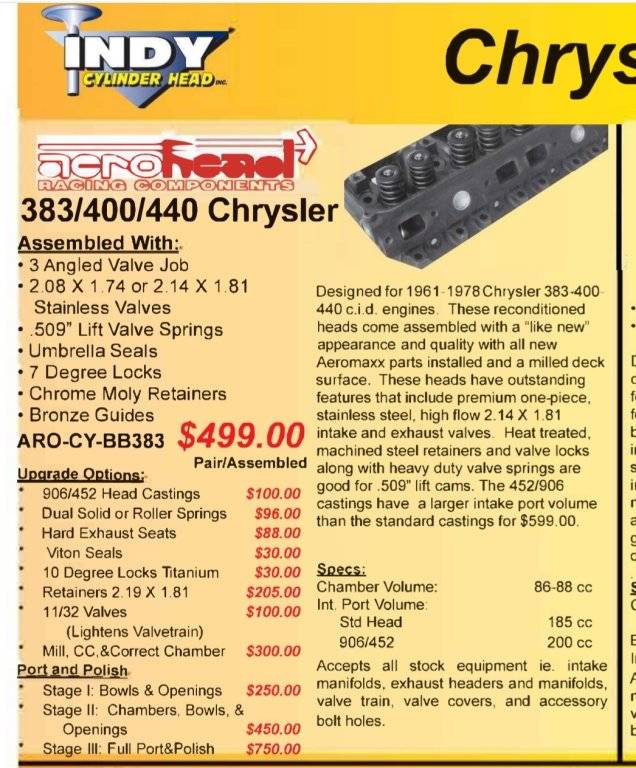

Here is my base plan, which was suggested to me by a very reputable mechanic years ago. 452 heads and hard exhaust seats these are the only comments he made at the time.

This is a new to me so I would appreciate any input and what might give me the most bang for the buck.

I am not looking for anything which will change her drivability. She has a 383, factory 4 barrel, cast exhaust manifold. No plans to change any of those components. Single exhaust but a dual exhaust is planned.

Here is my base plan, which was suggested to me by a very reputable mechanic years ago. 452 heads and hard exhaust seats these are the only comments he made at the time.

This is a new to me so I would appreciate any input and what might give me the most bang for the buck.