BillGrissom

Active Member

I posted a few months ago asking about gaskets, and there were several useful replies, but can't find it.

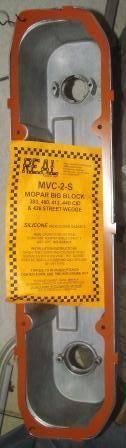

In searching for the recommended silicone gaskets, I found what looks like high-quality ones at less price - Real Gasket of Elizabethton, TN. They specialize in aircraft engine gaskets, but make some for collector vehicles. I bought both BB ($30.50) and SB ($25.20) sets. Chris signed the receipt as a Mopar Man with a 67 Cuda 440.

Unlike the photo, I ended up putting the gasket on the head, sliding the cover down, then attaching the tabs. I torqued to the spec'd 2 ft-lb, which is not much. The hard part was over an hour removing the bare silicone I used on the last pass. But the biggie was the broken stud fiasco.

It broke a few months ago when I tried tightening the nuts and forgot I had used jam nuts. I was able to drill it thru well-centered and was about to tap it out, which is the only success I have had removing broken bolts. Then I thought why not try a screw extractor since that will avoid thread damage. It broke off under not much torque (again!). Almost impossible to drill out the hardened steel, but I tried for hours. I understand some shops can burn one out. I almost drilled it using new Irwin bits and a carbide bit, but ended up just pushing it down and buggering up the threads. Later I will try installing a metric stud that is slightly bigger. For now, I hope the Holley cast aluminum cover is stiff enough to not require that stud.

In case you wonder about the harnesses in the photo, I have a Holley Projection TBI and Crane Cams electronic ignition.

In searching for the recommended silicone gaskets, I found what looks like high-quality ones at less price - Real Gasket of Elizabethton, TN. They specialize in aircraft engine gaskets, but make some for collector vehicles. I bought both BB ($30.50) and SB ($25.20) sets. Chris signed the receipt as a Mopar Man with a 67 Cuda 440.

Unlike the photo, I ended up putting the gasket on the head, sliding the cover down, then attaching the tabs. I torqued to the spec'd 2 ft-lb, which is not much. The hard part was over an hour removing the bare silicone I used on the last pass. But the biggie was the broken stud fiasco.

It broke a few months ago when I tried tightening the nuts and forgot I had used jam nuts. I was able to drill it thru well-centered and was about to tap it out, which is the only success I have had removing broken bolts. Then I thought why not try a screw extractor since that will avoid thread damage. It broke off under not much torque (again!). Almost impossible to drill out the hardened steel, but I tried for hours. I understand some shops can burn one out. I almost drilled it using new Irwin bits and a carbide bit, but ended up just pushing it down and buggering up the threads. Later I will try installing a metric stud that is slightly bigger. For now, I hope the Holley cast aluminum cover is stiff enough to not require that stud.

In case you wonder about the harnesses in the photo, I have a Holley Projection TBI and Crane Cams electronic ignition.

Last edited: