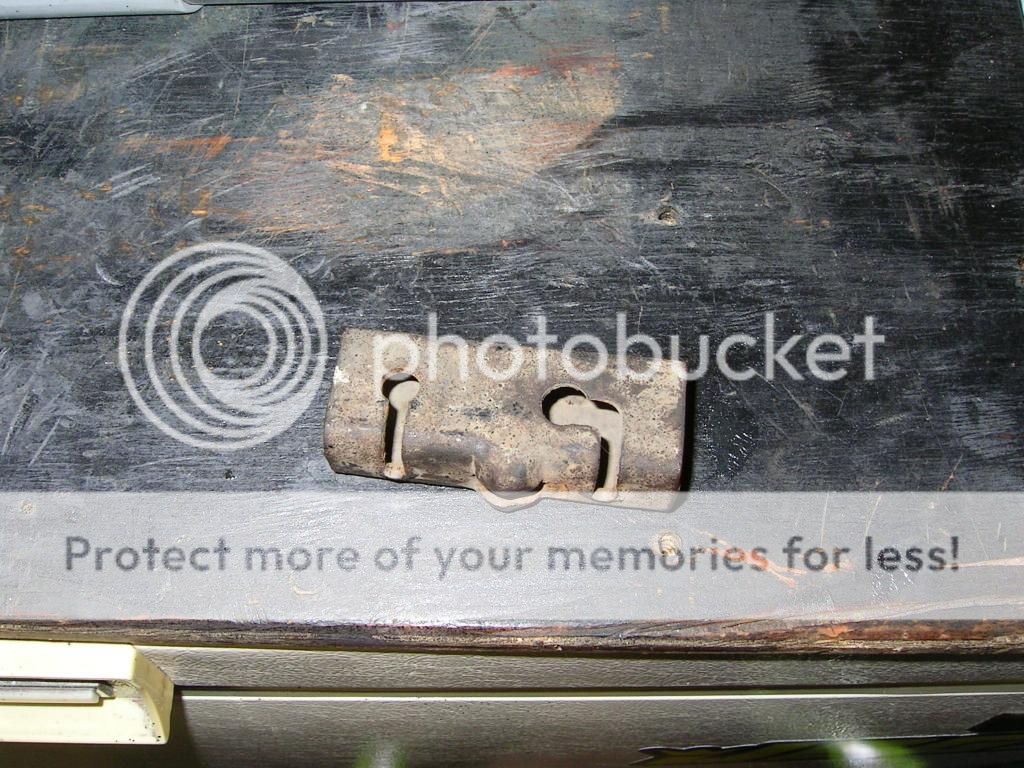

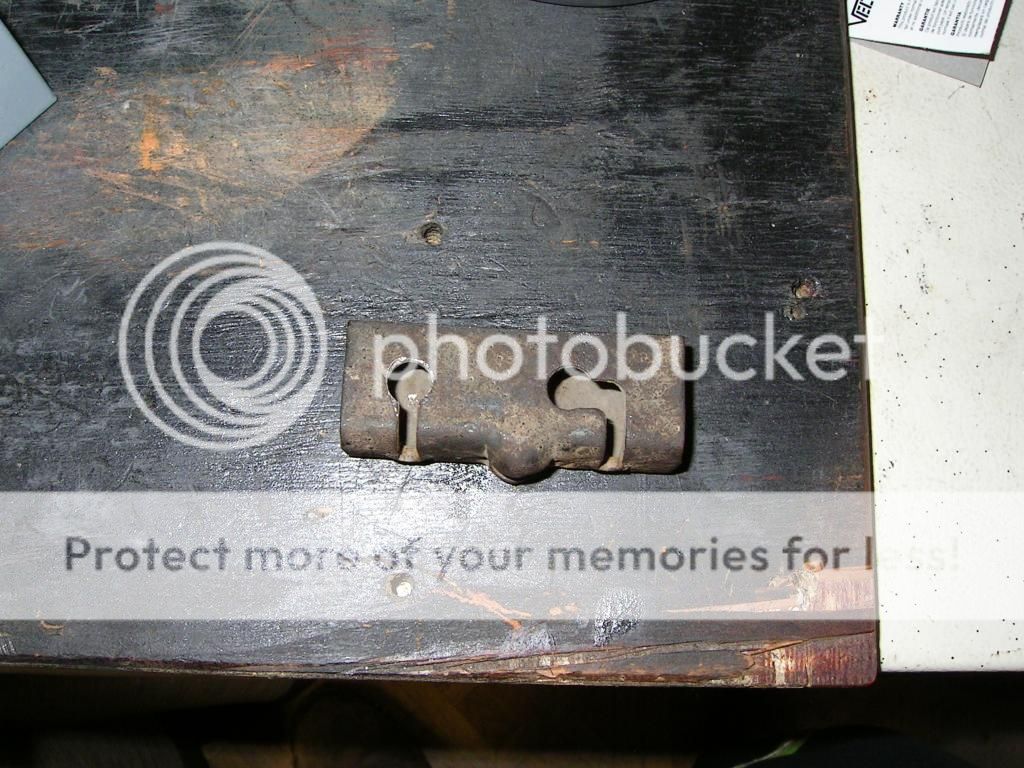

So back to the internet. This time I found a factory GM service update on how to adjust the rear E-brake. It said with the e-brake cable removed, and spring re-installed, that you had to push it forward and then let it go so it would "snap" back. This snapping would then cause the clutch to ratchet up the piston and get the proper 1/4" movement in teh e-brake lever. Only problem was it could take anywhere from 30-100 of these "snaps" to get things in place.

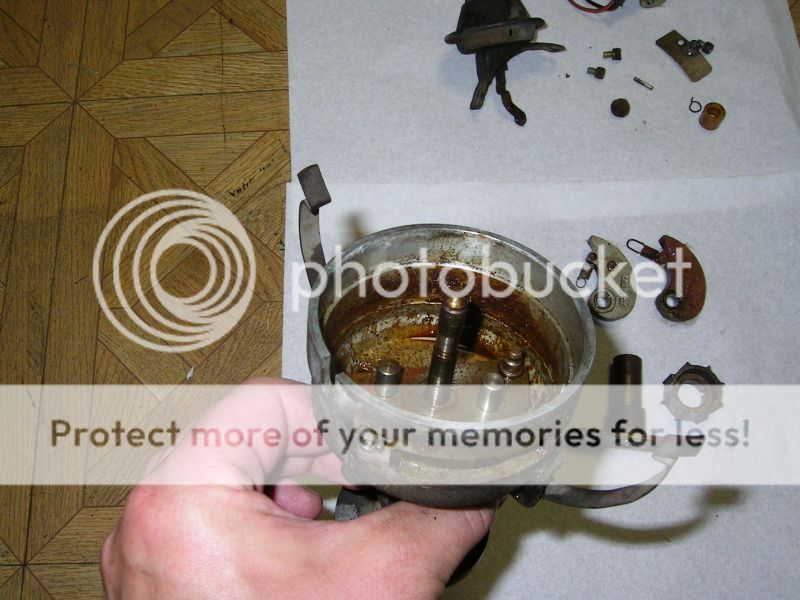

So back out to the wagona nd tried this....it seemed to work on the RH side...but just wasn't quite right. LH side...nope, nada...was not working. By this time I was about ready to pull everything, drop it in the dumpster and put the drums back on. I was sittign there looking at hings when a thought came to me...what if the calipers were binding up? So I decided to pull the caliper and check all the mounting points.

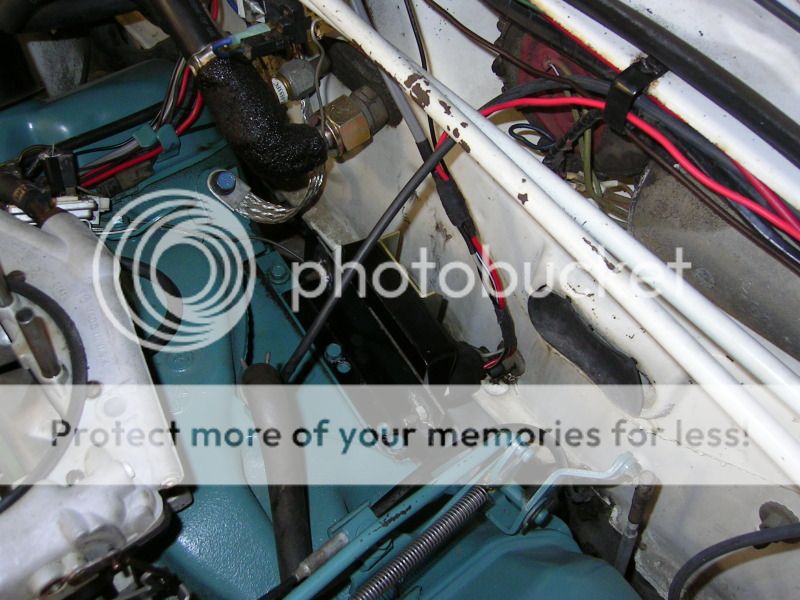

Turned out his was one of my major problems. I had primed and painted the scarbird brackets, as well as the calipers had a heavy coating of paint on them as well. So out came the sand paper, some never seize and then re-install. This time everything ratched up properly...I had the 1/4" movement for the E-brake levers and all was well!!