Mike Elenbaas

New Member

Hi all,

Not sure if this is common knowledge but thought I would share since I didn't know and have not seen this posted about yet. USCT is in the process of making subframe connectors spring relocators and minitubs for our C-body's! John went on to say they are also working on Gen3 hemi swap parts also and should have part numbers and listing for their C-body specific parts soon.

Hi Michael,

Funny you are asking - I have just completed the frame connectors and torque box designs for the C-Body and am working on the spring relocation right now!

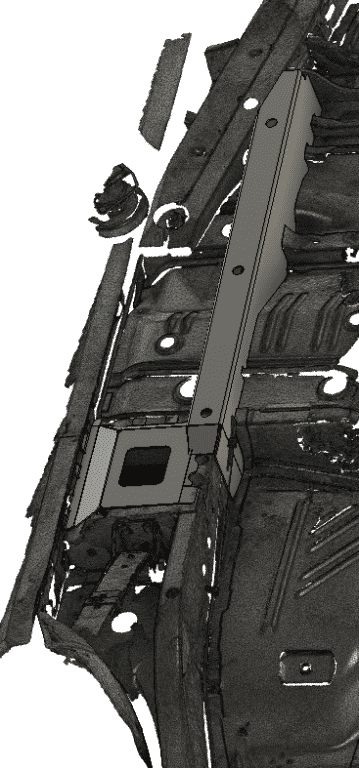

Here is a view of the CAD scan I made of the bottom of a 71 Fury with the frame connector and torque boxes located on the scan. Frame connectors are prototyped and complete as are the torque boxes - they are ready for production, spring relocation in a couple more days.

John Pasemann

Not sure if this is common knowledge but thought I would share since I didn't know and have not seen this posted about yet. USCT is in the process of making subframe connectors spring relocators and minitubs for our C-body's! John went on to say they are also working on Gen3 hemi swap parts also and should have part numbers and listing for their C-body specific parts soon.

Hi Michael,

Funny you are asking - I have just completed the frame connectors and torque box designs for the C-Body and am working on the spring relocation right now!

Here is a view of the CAD scan I made of the bottom of a 71 Fury with the frame connector and torque boxes located on the scan. Frame connectors are prototyped and complete as are the torque boxes - they are ready for production, spring relocation in a couple more days.

John Pasemann