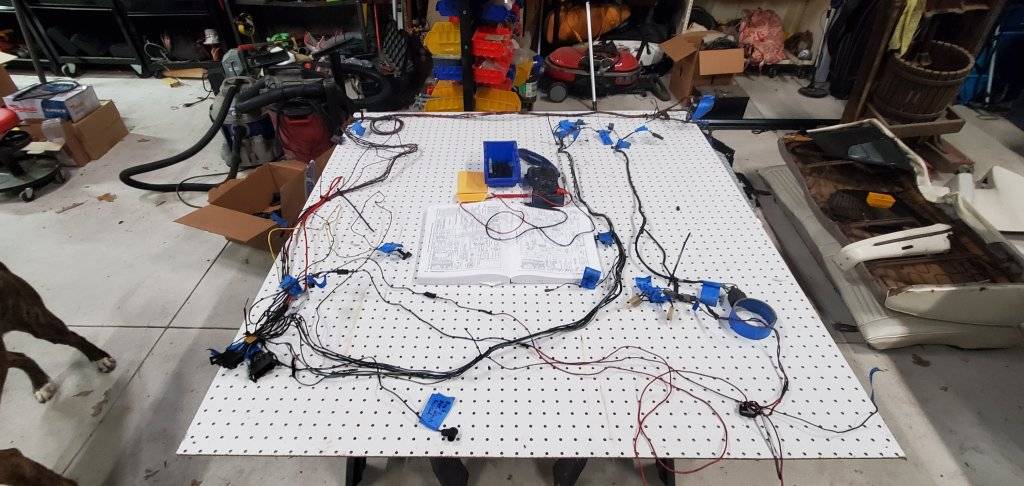

Pulled the engine and front end lighting harness out of my '68 300. Every wire in the car seems to have been cut and taped back together. Luckily no evidence of a fire but it looked like a real possibility. The firewall connectors look good so that will be reused after being cleaned up. Since I don't want to buy a new harness and I have the time I figured I would clean or replace all the connectors and make some adjustments while I have it on the bench.

- Add HEI module with new coil, removing the extra ballast resistor wiring and splicing the IGN1 and IGN2 together.

- Add electric choke wire for new Edelbrock Carb from IGN2 wire

- Remove mechanical voltage regulator and replace with solid state (D7018) to convert to a "one-wire" type alternator.

- Run new wires for the cornering lights as they were completely removed from the car.

- Add relays for the headlights

- Relocate the Headlight Door Cover relay into the engine compartment

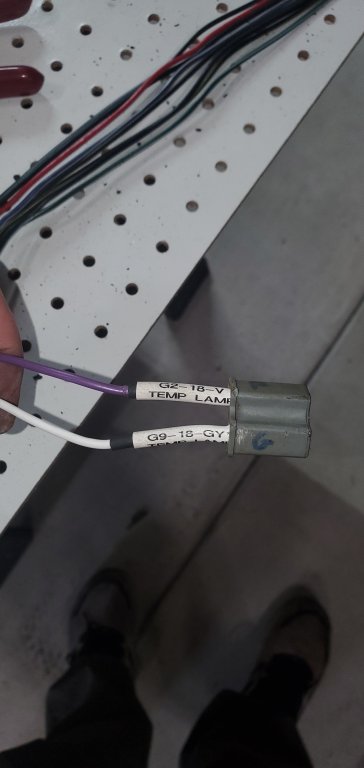

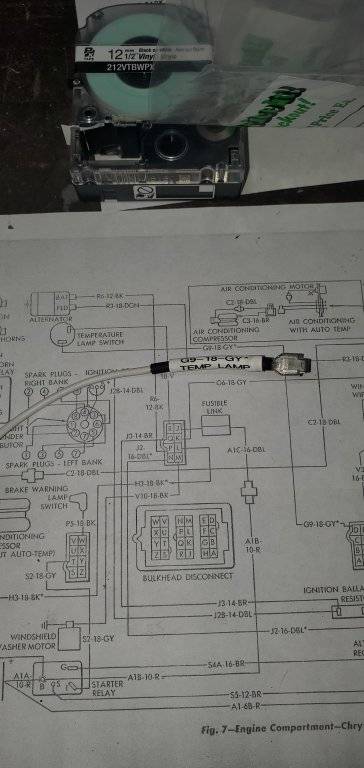

Every wire I touch will get a heat shrink label to help me or others in the future with troubleshooting. Wire colors are great until they all turn black or brown from dirt and grime! I have learned after doing the first plug for the temp lamp switch to not put the heat shrink so close to the end of the wire as it makes it difficult to reinsert into the connector.

Once I finish the engine compartment I will turn my attention to the wiring under the dash. Would like to get that done before I reinstall the heater box. Enjoying the wiring stuff way more than I thought!

- Add HEI module with new coil, removing the extra ballast resistor wiring and splicing the IGN1 and IGN2 together.

- Add electric choke wire for new Edelbrock Carb from IGN2 wire

- Remove mechanical voltage regulator and replace with solid state (D7018) to convert to a "one-wire" type alternator.

- Run new wires for the cornering lights as they were completely removed from the car.

- Add relays for the headlights

- Relocate the Headlight Door Cover relay into the engine compartment

Every wire I touch will get a heat shrink label to help me or others in the future with troubleshooting. Wire colors are great until they all turn black or brown from dirt and grime! I have learned after doing the first plug for the temp lamp switch to not put the heat shrink so close to the end of the wire as it makes it difficult to reinsert into the connector.

Once I finish the engine compartment I will turn my attention to the wiring under the dash. Would like to get that done before I reinstall the heater box. Enjoying the wiring stuff way more than I thought!

. Now I need to figure out why someone deleted the wiring for the cornering lights. Hopefully the correct switch is installed to run these when the blinker comes on. I read two different switches exist (red and white), red works with cornering lights, white does not. Will deal with that when I get under the dash.

. Now I need to figure out why someone deleted the wiring for the cornering lights. Hopefully the correct switch is installed to run these when the blinker comes on. I read two different switches exist (red and white), red works with cornering lights, white does not. Will deal with that when I get under the dash.