You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for 440 U-Code photo's

- Thread starter '69FuryIIIConvertible

- Start date

72Fury

Senior Member

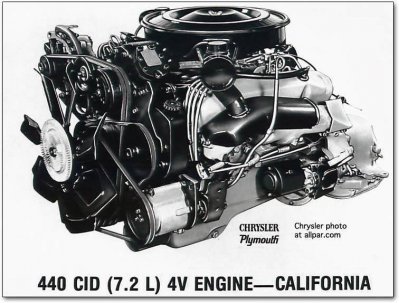

A California emission smog pump.

Wollfen

Old Man with a Hat

I havent ever seen one before, what is it connected to and how does it work?A California emission smog pump.

off- mission/product but another type of resource of "back-in-the-day" info.

surely there were other speed shops/builders where vintage R/RB photos and data could be found?

a sea of race hemis..off topic but an irresistible image

http://www.superbirdclub.com/InsideNichels.html

surely there were other speed shops/builders where vintage R/RB photos and data could be found?

a sea of race hemis..off topic but an irresistible image

http://www.superbirdclub.com/InsideNichels.html

I have never seen an air cleaner like the 440 at the bottom shows in the drawings in post 14. Probably a misprint?

yup..unsilenced element design with a snorkel hanging off it?

FWIW.....not a single 400 had an air pump. Don't know why either. In the later Formal years all engines including the slant 6 had an air pump.....except the 400. Still puzzling to me!

tbm3fan

Old Man with a Hat

I havent ever seen one before, what is it connected to and how does it work?

There is one on my car. The driven pump injects pressurized air into the exhaust stream to aid in better combustion of exhaust gases. Definitely old tech.

Fortunately, my car was not tampered with by the first owner (woman) who had it most of it's life.

A California emission smog pump.

I havent ever seen one before, what is it connected to and how does it work?

You probably have seen these on something, but it didn't register at the time. They are a popular delete item in the performance world. Generic smog pump information here. They came into use in the late 60s.All manufacturers used them at some point.

Until the catalytic converter they were used to pump air into the exhaust port to burn off combustion emissions, much like blowing on the embers of a weak fire to get it burning better. All systems use a check valve to stop exhaust coming backward to the pump and a valve to prevent backfires.

After the catalytic converter was introduced, they usually were used to blow at the exhaust port and to feed air to the catalyst so it could burn off combustion emissions (HC,CO). These systems had a switch over valve to control where the air was pumped (upstream,downstream)

They are still used today, but are usually electric and only blow to the exhaust port during warm up. Some of them are pretty hard to find as they are well hidden and much of their plumbing is cast into the heads.

They don't use much power and don't blow much pressure. The chief performance concerns are the extra heat at the exhaust valve possibly leading to detonation or burnt valves. If the engine is modified the anti backfire valves were usually vacuum controlled with ported vacuum and might not prevent all exhaust backfires. They also could cause a catalyst to overheat on very rich running cars, think lots of fuel and air, burning under your carpet, with just a few layers of sheet steel for protection.

They actually were first used on some performance models, the earliest I know of was the original z28 Cali package. While they don't really hurt performance themselves... the couple horses they consume and the above concerns made them an immediate removal item for the racey types.

commando1

Old Man with a Hat

Gonna have to change your name to Wikiflip.

Gonna have to change your name to Wikiflip.

I cant compete with the experience and research some of you more experienced gentlemen bring, so I try stick to what I know well. If I am useful, great... besides the catnip crowd has you beat to the renaming game... I'll answer to it all.

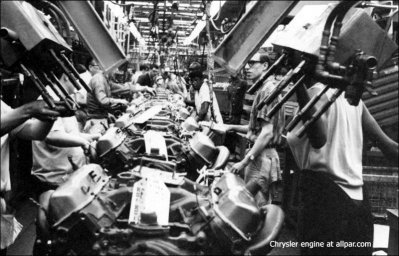

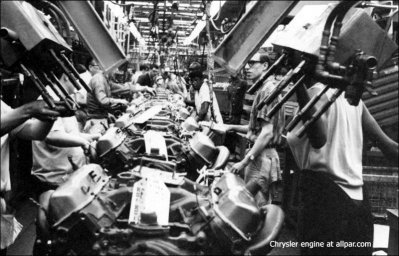

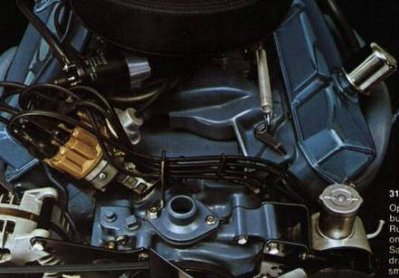

couple more from allpar (they sometimes mention peoples names - some may be willing to talk if you could find them?). again, good luck with the research!

i have been googling all sorta word combinations to try to find unmolested engine bays and/or cars, especially those depicted in black and white photos as best chance at "back in the day" products before all the maintenance/tinkering started.

really good color photos (may be too modern) of high-dollar rotisserie jobs of cars/engines MAY not have gotten it right -- so i didn't linger on those --BUT maybe 95% right is best we can do from here?

anyway, Trenton MI engine plant, May 21, 1968, celebrating 7 millionth engine. probably 1968 model year still in production, but at least we can see some visual details of what this plant was actually building.

http://www.allpar.com/corporate/factories/trenton-engine/7-million.html

i have been googling all sorta word combinations to try to find unmolested engine bays and/or cars, especially those depicted in black and white photos as best chance at "back in the day" products before all the maintenance/tinkering started.

really good color photos (may be too modern) of high-dollar rotisserie jobs of cars/engines MAY not have gotten it right -- so i didn't linger on those --BUT maybe 95% right is best we can do from here?

anyway, Trenton MI engine plant, May 21, 1968, celebrating 7 millionth engine. probably 1968 model year still in production, but at least we can see some visual details of what this plant was actually building.

http://www.allpar.com/corporate/factories/trenton-engine/7-million.html

Last edited:

commando1

Old Man with a Hat

These pics prove to me that the accelerator return spring bracket is NOT engine colored despite all the "correct" restorations.

-5 points....

-5 points....

Wollfen

Old Man with a Hat

I see it in the pic and it is engine color.These pics prove to me that the accelerator return spring bracket is NOT engine colored despite all the "correct" restorations.

-5 points....

Wollfen

Old Man with a Hat

MrMoparCHP

Old Man with a Hat

To get this post back on topic the pictures are of little use unless you know the application. Also these pictures do little to illustrate the differences between years and models.

In working on my car I have seen some differences.

1. Throttle bracket, I have yet to see another one like mine (on any car/application).

2. Starter cable bracket on the back of the driver side head, nobody here knew of it. Not all 69 C-Body HP 440 had it.

Things lo look at, alternator and power steering brackets along with pulleys. Something over the years i have seen a wide variety in.

This just takes me back to my first comment, what is it you are looking for?

Alan

In working on my car I have seen some differences.

1. Throttle bracket, I have yet to see another one like mine (on any car/application).

2. Starter cable bracket on the back of the driver side head, nobody here knew of it. Not all 69 C-Body HP 440 had it.

Things lo look at, alternator and power steering brackets along with pulleys. Something over the years i have seen a wide variety in.

This just takes me back to my first comment, what is it you are looking for?

Alan

These pics prove to me that the accelerator return spring bracket is NOT engine colored despite all the "correct" restorations.

-5 points....

There it is enlarged.

View attachment 66490

i have NO idea and am not taking a position...you fellas swim deeper into the knowledge pool than me.

Trenton pic it does look engine color to me too but its harder to see given quality of the underlying allpar photo.

the ad version shows a NON-engine color piece but then again NON-production parts were often used in those shoots due to modei year lead time issues for the ad campaigns.

if bracket was attached then painted when removed you'd see that "shadow" underneath and the screw would be engine color?.

on the other hand, we know the engines probably weren't painted with the carbs attached, so maybe at that carb attachment operation on the line the bracket was added. so likely it was NOT engine color but rather that flat black color?

there will be dozens little things like this to sort out to complete this mission ;)

Last edited:

Wollfen

Old Man with a Hat

The bolt is put in at a certain point of the production line and the bracket is put on at the same time, the carb and distributor etc are put on later and the line worker does not have to firstly have a socket to undo the bolt to put the bracket on then and doesn't have to worry about retorqueing it to original specs again. It saves these extra steps. One of the things they did on the production line was to keep things simple. The fuel pump, water pump oil pump and exhausts were all put on before the painting stage. Once painted all that was need was to bolt things on, not have to take anything off again. That extra step would introduce a potential weak point, what if the undone bolt wasn't torqued back properly? Not necessary when you understand that whether the accelerator bracket being painted or not wasn't an issue and as such was not of concern. Let it be painted, it simplifies the production line process. Look at the engine in front of the engines in the row, it is unpainted. While you cant see much of it, it does give clues.if bracket was attached then painted when removed you'd see that "shadow" underneath and the screw would be engine color?.

on the other hand, we know the engines probably weren't painted with the carbs attached, so maybe at that carb attachment operation on the line the bracket was added. so likely it was NOT engine color but rather that flat black color?

there will be dozens little things like this to sort out to complete this mission ;)

yup, it could very likely have been done exactly as you noted above.

they had pretty smart IE's, ME's, and skilled-trades folks back then too, and wasted motion = wasted time = wasted money (non-lean production, as well as poor error-proofing leading to defects/non-compliant parts) was something to be avoided, then and especially now.

just trying to give 69furyIIIconvertible more and more "breadcrumbs" to follow as he scopes out his mission plan. but along the way interesting things come up from back when people at least my age were in elementary school. ;)

they had pretty smart IE's, ME's, and skilled-trades folks back then too, and wasted motion = wasted time = wasted money (non-lean production, as well as poor error-proofing leading to defects/non-compliant parts) was something to be avoided, then and especially now.

just trying to give 69furyIIIconvertible more and more "breadcrumbs" to follow as he scopes out his mission plan. but along the way interesting things come up from back when people at least my age were in elementary school. ;)

commando1

Old Man with a Hat

You can tell from a b&w photo?There it is enlarged.

View attachment 66490

Similar threads

- Replies

- 6

- Views

- 830

- Replies

- 3

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 1

- Views

- 1K