jesus5052003

New Member

How do I read on this rear air conditioner in my 1968 plymouth sports suburban station wagon c-body 383 4bbl and how easy is it to convert or should I look for someone that adds R-12 to recharge

Not claiming you're wrong, but I had a '92 Daytona I emptied the old refrigerant, and added the 134 to the system with no other change. It worked great for the three years I had the car. Nice cold air with no dropoff in performance. At the time, it was common to change a couple of smaller parts in the system and it functioned as normal. I just wasn't putting any money into that particular car, and all things worked fine for me.R-12 dual evaporator units will usually fail if you convert them to R-134a. It is really difficult to get all of the mineral type oil out of a dual unit R-12 system prior to converting to R-134a. Any oil left in the system will turn into a jelly like snot that will not circulate and the system will likely die of oil starvation. Even with the old oil removed, R-134a is a less dense refrigerant that does not circulate oil very well, especially on dual unit systems. Ideally, you should find a shop to evacuate the system, replace the filter dryer. check for leaks, recharge the system with fresh oil and recharge it with R-12. There are also some R-12 replacement gasses available that will work better in these old systems than R-134a. R-134a is in the process of being phased out anyway. R-12 replacements are a mostly Propane/Butane blend, so there is a potential fire hazard if the gas were to happen to leak out around an electrical arc or an open flame.

Dave

The reason your Datona "lived" is that it had a rotary vane style compressor rather that than a piston type. Makes a big difference because the rotary compressor are a lot more forgiving.Not claiming you're wrong, but I had a '92 Daytona I emptied the old refrigerant, and added the 134 to the system with no other change. It worked great for the three years I had the car. Nice cold air with no dropoff in performance. At the time, it was common to change a couple of smaller parts in the system and it functioned as normal. I just wasn't putting any money into that particular car, and all things worked fine for me.

Air conditioning systems are relatively simple. As you describe, there are a few components. Leaking makes up over 90% of the issues.My 66 wagon with Dual AC was converted to R134a freon in the late 1990s - and still lives to tell the tale. It still cools like a freezer in there, both front and rear units. It stayed R134a for at least 20 years. I actually don't use R134A any more, I use the various Butane-based freons because it's cheaper. I guess the original evacuation was complete and no original oil remained when the system was converted. Any subsequent flushing done was done at multiple points to ensure completeness.

Regardless - there are several steps required before just recharging:

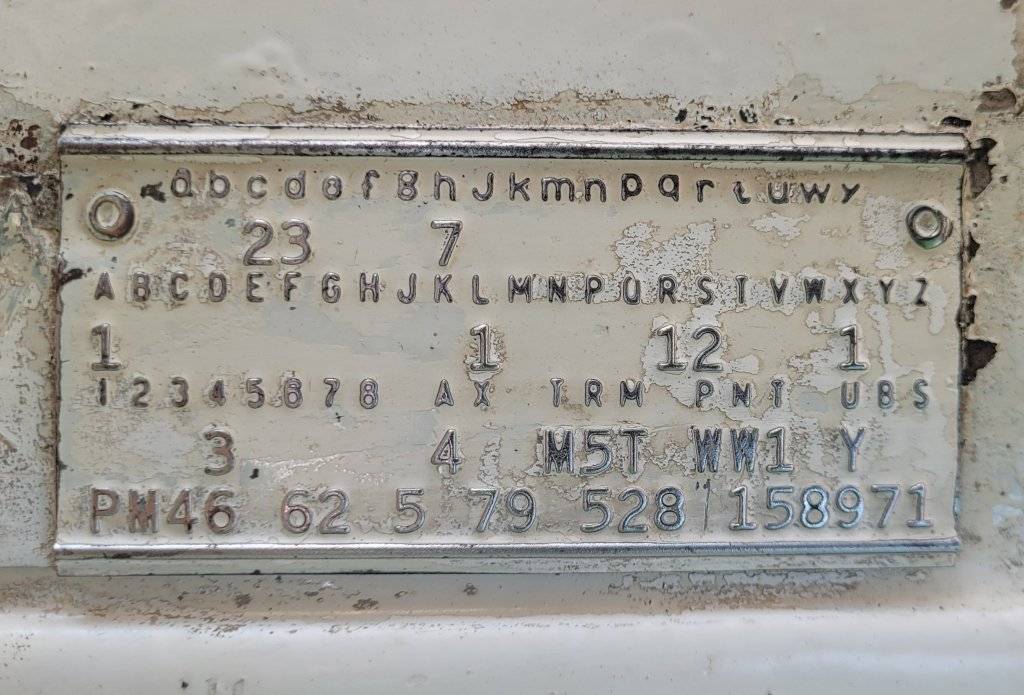

Dual AC systems such as that have their charge weights on a tag on the compressor - there is no information for that on the fender tag you posted. Typically, the dual systems in our C bodies used roughly 4 lbs of R12, but that's really not required information - yet.

First, the system has to be evacuated and see if it holds a vacuum. If it doesn't, there's a leak which needs repairing. This should be done by an AC shop - they can fill the system with an appropriate gas with a dye in it that shows leaks with UV light.

Once the leaks are repaired and the system holds vacuum (AND the compressor is able to do its job, and the pressure valves function), then you can charge the system.

Most charge weights are generic - meaning one size sort of fits all - but the best way to charge the system is to put in about 50% of a charge and start watching the temperatures at the vents. Gradually add a bit more refrigerant, and as the temps decend, watch for when they bottom out and start to rise. Take a bit of refrigerant out and that's where your system will operate the best.

Doesn't really matter what refigerant you choose to use - have it truly cleaned of every bit of old oils first by flushing at each of the major unions - replace the O rings as you go with green ones, use the proper oil that goes with the new refrigerant, and go slowly.

I have found that for R134a, about 60 - 80% of the original charge weight for R12 is about where you'll be. Butane types are maybe a tad less than that.

You do NOT need to replace all your original rubber lines if they're not leaking - that's a money grab - old barrier hoses are seasoned and will not allow new refrigerants to seep through. NEW hoses MUST be compatible with modern refrigerants, or they will leak through the material. All my original hoses are fine, no leaks or seepage.

The same with the O rings at unions - no reason to change them if they're not leaking, UNLESS you've opened the system at that point for flushing - then change the O ring to a new green one.

AC systems are actually quite simple - lots of parts, but they basically fall into these categories, and so can be gone through methodically:

Compressor

Lines

Condenser

Evaporator

Pressure regulator valves

All of these can get gummed up from poor prep and incomplete flushing when switching to new oils and refrigerants, and can stop working and require cleaning or replacement. Almost every single part is available new except for hard lines which are rarely requiring replacement, so if in doubt, replace it, or in the case of the compressor, while it's a pain, it can be rebuilt. I've gotten lucky with my compressors - again, if the prep work is done when recharging (proper flushing etc.), they're very rugged units.

From what I have heard, to do a correct conversion to R134a, you have to change out all the A/C hoses to the new barrier type. R134a is a smaller molecule than R12 and will escape out of the old R12 hoses. So if you convert and do not change over the hoses, you will be continually adding R134a as it will leak out of the R12 hoses. Given the increasing scarcity of R12 it is a good idea to replace the factory hoses with R134 barrier hoses to help prevent leaks. I'm told any good A/C shop can make up custom hoses. However this does make things a more expensive proposition. Here is an article with good info about R12 and R134: Air-conditioning dos and don’ts: Refrigerants and the law - Hagerty Media

what kind of ac compressor r u going to use with the 134a? i how not the RV2? WITH OUT A POA 134 Valve( they dont mak one now !) IT WILL NOT work RIGHT u can switch it over tp a rotary style but its a differant belt set up . i know i fought that wih my 72 440 new yorkerIf you just upgraded to the newer barrier hoses, the older "barb" OEM connectors would pierce the barrier and leaks would happen. This is the reason for the newer "bead-lock" connectors and distinctive clamping pattern on the hose ends. No piercing of the inner barrier, that way.

A LOT has been learned since R-134a was first used. A main thing is that the R-12 oil seasons (and seals) the innards of the hoses and related connections. If they are not leaking with R-12, they will not typically leak with R-134a. So rather than a "replace" orientation to hoses, it becomes a "try it and see with R-134a gas". In many cases, the old hoses are aged and need replacement anyway, so prepare to use all new hoses, connectors, and o-rings in the system. Plus a new receiver-drier too.

On many C-bodies, the metal lines which run along the rh upper fender do not need to be replaced, unless they are leaking and can't be brazed back together.

Search for a thread by "TxDon" on converting his '66 Monaco wagon to R-134a. He managed to source everything to do the deal for pretty good prices. Some assy required, though.

As things have evolved, "Better Living Through Chemistry" has happened as rather than three oils, there are fewer oils which can have universal compatibility with R-12, R-134a, and others.

R-134a is related to the newer gas now used in current OEM systems. That gas is very expensive, which definitely requires a recycling machine! As I have noticed an online mechanic has used R-52 as a drop-in replacement. R-134a might be on the way out, but it might still be a good while before that happens.

Enjoy