--> G A S K E T S <--

After the debacle with DMT, I contacted companies in Germany who could possibly make all my Gaskets. I did all the hard work myself by creating perfect fitting templates and af all the gaskets and provided digital data of all of them, still they all wanted a fortune just to cut them out (around 500€ for a set of all gaskets).

I decided to take matter into my own handy (again) and make my own gaskets. So I searched the web to find a way and stumbled across the Cricut Maker 3, a cutting plotter, initially made for (mostly women) to cut crafting materials... After researching the abilities of the machine, I finally made the move and bought a Maker 3 + Tools for ~600€. Yes, a lot of money as well, but now I can make as many gaskets as I want and even sell sets of rare gaskets no one in the market makes. I’m open for that if someone is interested. Just shoot me a PM.

After a bit fiddling around with the machine, I now have made all my gaskets no one makes and they are all a perfect fit!

After the first successfully made gaskets, I felt like I made fire for the first time! Soo satisfying!

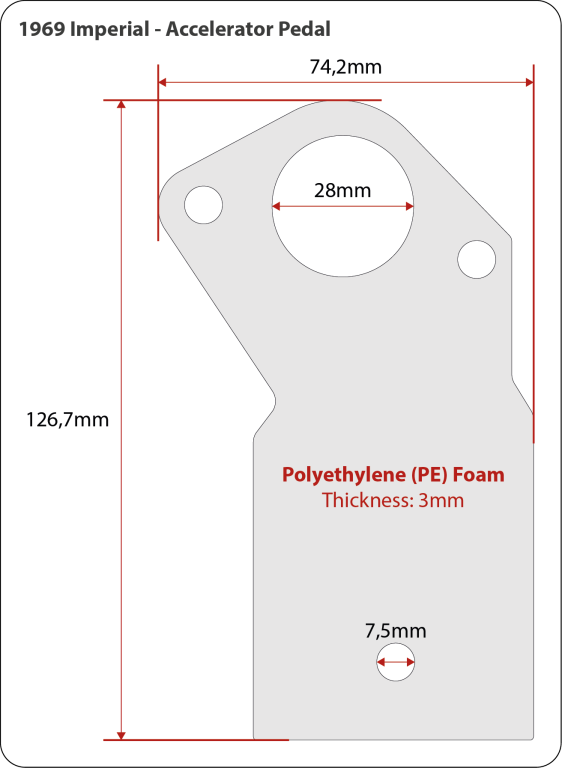

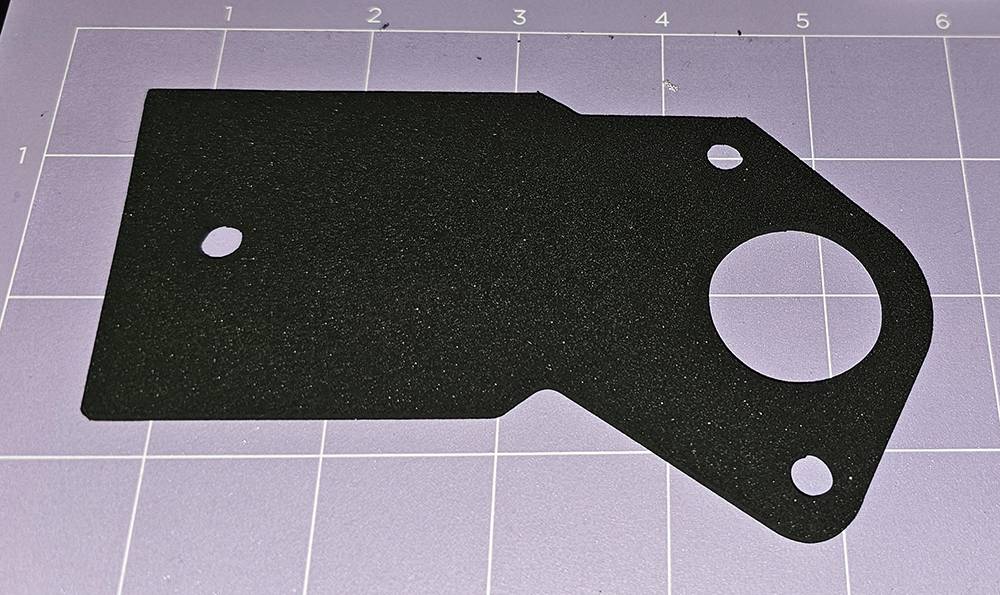

Accelerator Pedal

The OEM material is a PE-foam and I will make gaskets with the correct material soon, but for now, I made it from EPDM Cellular Rubber since I had the material already. Should not make a difference, just doesn’t look OEM.

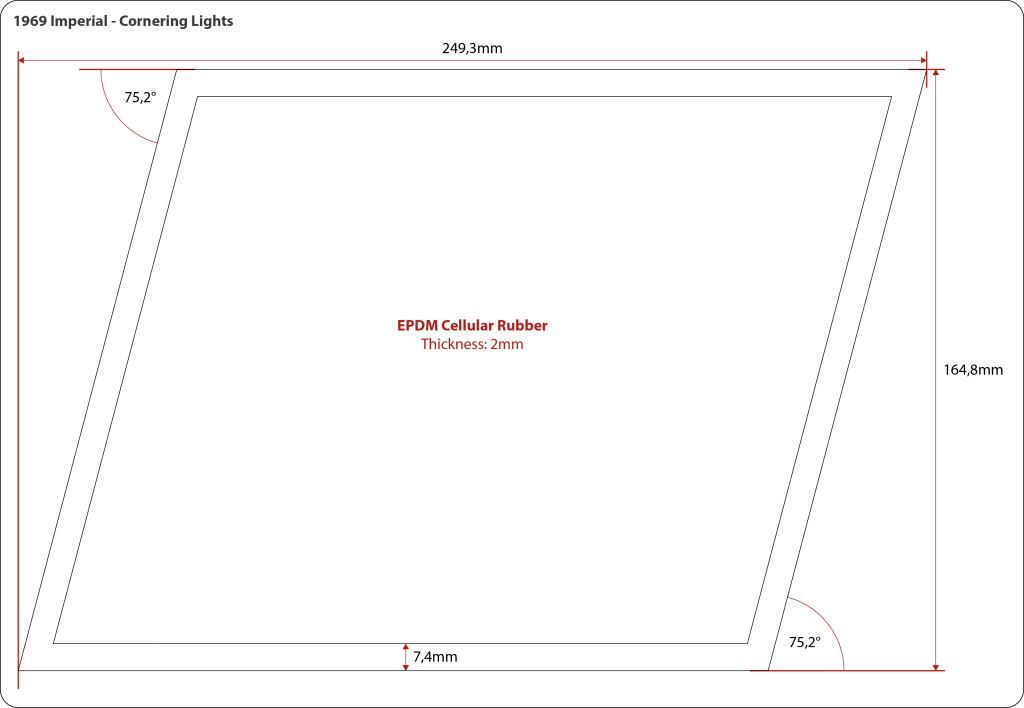

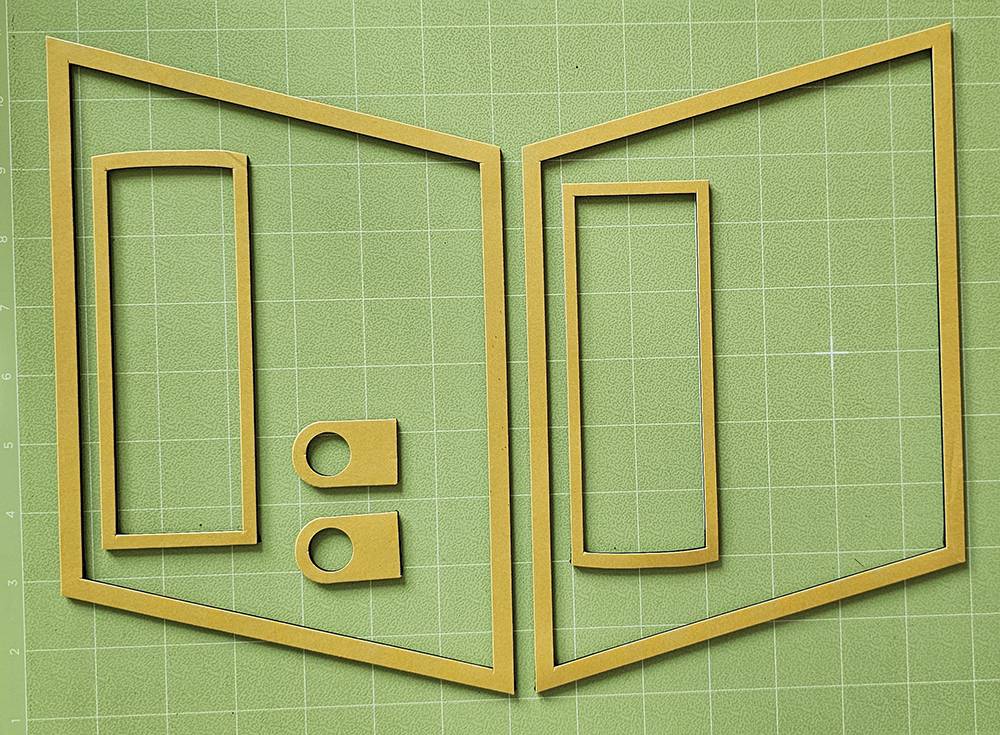

Cornering Lights

The EPDM Cellular Rubber is just like the EOM material, but black instead of the original grey material. I used adhesive backing foam, so I don’t have the glue the gaskets down separately like the factory did back then.

After the debacle with DMT, I contacted companies in Germany who could possibly make all my Gaskets. I did all the hard work myself by creating perfect fitting templates and af all the gaskets and provided digital data of all of them, still they all wanted a fortune just to cut them out (around 500€ for a set of all gaskets).

I decided to take matter into my own handy (again) and make my own gaskets. So I searched the web to find a way and stumbled across the Cricut Maker 3, a cutting plotter, initially made for (mostly women) to cut crafting materials... After researching the abilities of the machine, I finally made the move and bought a Maker 3 + Tools for ~600€. Yes, a lot of money as well, but now I can make as many gaskets as I want and even sell sets of rare gaskets no one in the market makes. I’m open for that if someone is interested. Just shoot me a PM.

After a bit fiddling around with the machine, I now have made all my gaskets no one makes and they are all a perfect fit!

After the first successfully made gaskets, I felt like I made fire for the first time! Soo satisfying!

Accelerator Pedal

The OEM material is a PE-foam and I will make gaskets with the correct material soon, but for now, I made it from EPDM Cellular Rubber since I had the material already. Should not make a difference, just doesn’t look OEM.

Cornering Lights

The EPDM Cellular Rubber is just like the EOM material, but black instead of the original grey material. I used adhesive backing foam, so I don’t have the glue the gaskets down separately like the factory did back then.