Hey guys and gals, I recently got my 65 Fury II 4 door up and running and I've been screwing around with the Stromberg WW 2 BBl set on top of the 318 poly head. The heads have been milled to achieve 10:1 compression and the cam is a 264 .450 solid lifter. I have the tti headers hooked to their H pipe dual exhaust with hush thrush mufflers on the end. I got the choke and idle nice and smooth. However I am having an issue. When I am cruising at any speed I have an ever so slight stumble feeling and if I get in on the gas pedal slightly there is a "dead spot" but comes out of it once you push on the pedal. Also if I take a 90 degree turn and try and accelerate she stalls out sometimes. Same with reverse which is a new thing as of tonight backing out of driveway and I go to give it gas. I did try the different adjustments of the accelerator pump and the best adjustment was in the middle which is what it was set at at stock. The carb is a reman carb that came with the car but I do have the original which I plan on rebuilding. Another thing to note is that my fuel filter is only about half full and it was full at the beginning of the day. Any help would be awesome

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Carb issue?

- Thread starter Rooster34

- Start date

If it's a Tomco carb, like from Oriellys etc, it's junk, period.

Pump could be weak, do a volume test. Disable ignition, unhook line at carb and put into a 16 oz bottle and crank, should fill the bottle real quickly and evenly. If not , check pump, and search for pinholes in the fuel line. If sender is original, it could have pinholes causing low fuel volume

Pump could be weak, do a volume test. Disable ignition, unhook line at carb and put into a 16 oz bottle and crank, should fill the bottle real quickly and evenly. If not , check pump, and search for pinholes in the fuel line. If sender is original, it could have pinholes causing low fuel volume

In addition to checking the fuel supply to the carb, check the float level adjustment, it may be set too low. You have significantly modified this engine and it now needs more fuel. The symptoms you describe suggest that the carb is too lean. On acceleration the accelerator pump might cause a dead spot, surging or stumbling at a steady speed means that the main jets are probably too small. Check the leather on the accelerator pump, these can fail pretty quickly if you are running moonshine blend fuel. Also check your points for gap and resistance as weak spark can also cause the problems you are describing.

Dave

Dave

Yeah I am wondering if one of my lines got clogged with some sediment from the tank. It has the original tank and I recently just filled it with 93 which I'm sure stirred up some ****. I have all new plugs, wires, rotor and cap. I did mess around with the accelerator pump adjustment, but come to think of it the carb sat out while I was rebuilding the engine and the leather could have dried out on the pump. Sboild I still check the point gaps and resistance even though that is all new?In addition to checking the fuel supply to the carb, check the float level adjustment, it may be set too low. You have significantly modified this engine and it now needs more fuel. The symptoms you describe suggest that the carb is too lean. On acceleration the accelerator pump might cause a dead spot, surging or stumbling at a steady speed means that the main jets are probably too small. Check the leather on the accelerator pump, these can fail pretty quickly if you are running moonshine blend fuel. Also check your points for gap and resistance as weak spark can also cause the problems you are describing.

Dave

Its a Stromberg WW3If it's a Tomco carb, like from Oriellys etc, it's junk, period.

Pump could be weak, do a volume test. Disable ignition, unhook line at carb and put into a 16 oz bottle and crank, should fill the bottle real quickly and evenly. If not , check pump, and search for pinholes in the fuel line. If sender is original, it could have pinholes causing low fuel volume

That is a bit more cam than the original, so the carb might need an upgrade to a 500cfm 4bbl, which is not much smaller than the ones on the 383s that model year. 600 would probably work, too, fwiw. On the other hand, a carb from a similar model year 383 might work, too, IF the bolt pattern size on the manifold will work with the later carb.

At what road speeds are the sags happening? If these issues are just off-idle, then the cam is making the engine need more air, which means the throttle blades are open too far, enough to put the transition slots in play, which is not unlike putting a bigger cam in a larger V-8 and using the stock 4bbl with it. Which is why the additional holes are drilled in the throttle plates. To allow more air past the throttle plates at idle, but also put the relationship of the throttle plates to the idle and transition ports into their designed relationship.

What idle rpm in "N"? Just curious. In "D" with the brakes fully applied? What ignition timing?

I don't know that the better exhaust system might be affecting the idle settings, but they surely might be affecting the fuel curve at "driving apm" a bit. Which might be a lost cause trying to re-calibrate the two bbl carb due to lack of jets to do it with. Which you probably didn't want to hear. You might contact FCBO member Dana at Woodruff Carb and see what he thinks.

Enjoy!

CBODY67

At what road speeds are the sags happening? If these issues are just off-idle, then the cam is making the engine need more air, which means the throttle blades are open too far, enough to put the transition slots in play, which is not unlike putting a bigger cam in a larger V-8 and using the stock 4bbl with it. Which is why the additional holes are drilled in the throttle plates. To allow more air past the throttle plates at idle, but also put the relationship of the throttle plates to the idle and transition ports into their designed relationship.

What idle rpm in "N"? Just curious. In "D" with the brakes fully applied? What ignition timing?

I don't know that the better exhaust system might be affecting the idle settings, but they surely might be affecting the fuel curve at "driving apm" a bit. Which might be a lost cause trying to re-calibrate the two bbl carb due to lack of jets to do it with. Which you probably didn't want to hear. You might contact FCBO member Dana at Woodruff Carb and see what he thinks.

Enjoy!

CBODY67

Thanks for the info! I was planning on upgrading the carb to a 500 cfm next year sometime but wanted to see if I could get the stromberg there. The "sags" or stumble happen at cruising speed all the way through which was down my road at 40 mph at about 1600 rpm. Idle in N is about 700 and when brakes are applied and in D I think its about 550-600 but will confirm later today.That is a bit more cam than the original, so the carb might need an upgrade to a 500cfm 4bbl, which is not much smaller than the ones on the 383s that model year. 600 would probably work, too, fwiw. On the other hand, a carb from a similar model year 383 might work, too, IF the bolt pattern size on the manifold will work with the later carb.

At what road speeds are the sags happening? If these issues are just off-idle, then the cam is making the engine need more air, which means the throttle blades are open too far, enough to put the transition slots in play, which is not unlike putting a bigger cam in a larger V-8 and using the stock 4bbl with it. Which is why the additional holes are drilled in the throttle plates. To allow more air past the throttle plates at idle, but also put the relationship of the throttle plates to the idle and transition ports into their designed relationship.

What idle rpm in "N"? Just curious. In "D" with the brakes fully applied? What ignition timing?

I don't know that the better exhaust system might be affecting the idle settings, but they surely might be affecting the fuel curve at "driving apm" a bit. Which might be a lost cause trying to re-calibrate the two bbl carb due to lack of jets to do it with. Which you probably didn't want to hear. You might contact FCBO member Dana at Woodruff Carb and see what he thinks.

Enjoy!

CBODY67

Also the total timing is 32 degreesThat is a bit more cam than the original, so the carb might need an upgrade to a 500cfm 4bbl, which is not much smaller than the ones on the 383s that model year. 600 would probably work, too, fwiw. On the other hand, a carb from a similar model year 383 might work, too, IF the bolt pattern size on the manifold will work with the later carb.

At what road speeds are the sags happening? If these issues are just off-idle, then the cam is making the engine need more air, which means the throttle blades are open too far, enough to put the transition slots in play, which is not unlike putting a bigger cam in a larger V-8 and using the stock 4bbl with it. Which is why the additional holes are drilled in the throttle plates. To allow more air past the throttle plates at idle, but also put the relationship of the throttle plates to the idle and transition ports into their designed relationship.

What idle rpm in "N"? Just curious. In "D" with the brakes fully applied? What ignition timing?

I don't know that the better exhaust system might be affecting the idle settings, but they surely might be affecting the fuel curve at "driving apm" a bit. Which might be a lost cause trying to re-calibrate the two bbl carb due to lack of jets to do it with. Which you probably didn't want to hear. You might contact FCBO member Dana at Woodruff Carb and see what he thinks.

Enjoy!

CBODY67

Thanks for the updates. Things sound like they are "ball park", as to idle speeds and such.

You might notice the amount of throttle pedal travel it takes to do the various road speeds where the sags happen. Then with the enging stopped, duplicate those same throttle settings and then see how much accel pump shot happens when more throttle is added past those points.

Past a certain point, the accel pump shot is not really needed as the "power piston" takes over when manifold vacuum drops past a certain point. The accel pump is temporary, as the power piston mixture is constant as long as the vacuum is below a certain level. Like 5" hg, which is where most Holley power valves open.

Our '66 Newport 383 had a Stromberg WWC3-262 2bbl carb on it. I liked the (what I considered more modern) design of the carb, when compared to the Carter BBD. My '80 Newport 360 has a 318-size BBD on it, OEM. Not a bad carb, once I learned more about it. Not sure if your WWC is prone to the same issues as the larger WWCs on 383? Does the air cleaner "clamp" onto the carb, rather than having a center carb stud and wing nut?

In the mean time, you might tweak the tune-up settings and see how things go. Maybe a bit more base timing? All the while accumulating $$$ and throttle linkage items for the 4bbl upgrade in the future.

Take care,

CBODY67

You might notice the amount of throttle pedal travel it takes to do the various road speeds where the sags happen. Then with the enging stopped, duplicate those same throttle settings and then see how much accel pump shot happens when more throttle is added past those points.

Past a certain point, the accel pump shot is not really needed as the "power piston" takes over when manifold vacuum drops past a certain point. The accel pump is temporary, as the power piston mixture is constant as long as the vacuum is below a certain level. Like 5" hg, which is where most Holley power valves open.

Our '66 Newport 383 had a Stromberg WWC3-262 2bbl carb on it. I liked the (what I considered more modern) design of the carb, when compared to the Carter BBD. My '80 Newport 360 has a 318-size BBD on it, OEM. Not a bad carb, once I learned more about it. Not sure if your WWC is prone to the same issues as the larger WWCs on 383? Does the air cleaner "clamp" onto the carb, rather than having a center carb stud and wing nut?

In the mean time, you might tweak the tune-up settings and see how things go. Maybe a bit more base timing? All the while accumulating $$$ and throttle linkage items for the 4bbl upgrade in the future.

Take care,

CBODY67

Ok, ill have to do that in the spring time! I just drove it to my storage hanger before the big storm rolls in tonight and shits a bunch of snow all over us.anything that has a light pedal pressure it stumbles. Taking a turn lightly on the gas, stalls out, (so maybe a bowl float issue there?) As i understand the accel pump is just for the initial "prime" when you are at cruising speeds and step on the gas as if you were passing someone. It gives a "shot" of fuel to the carb so its smooth until the power piston catches up so to speak(picture show power piston on the and accel pump on right with spring. It does not like light pedal pressure.Yes the WW has the air cleaning housing tighten around the air horn, and I've read that it can warp the horn and the **** gets f'd. Is there a way to tell if it wrapped? I am planning on rebuilding the carb that came original to the car when it was first purchased in 1965 and possibly drilling the jets to make them bigger, my father in law knows how to do all that. And the one that sits on there now is a remanned stromberg and I figured ill take that off, see how the one I rebuilt runs and then rebuild the reman one. And if they both suck then I plan on getting a holley 500cfm 2bbl. And selling the strombergs.Thanks for the updates. Things sound like they are "ball park", as to idle speeds and such.

You might notice the amount of throttle pedal travel it takes to do the various road speeds where the sags happen. Then with the enging stopped, duplicate those same throttle settings and then see how much accel pump shot happens when more throttle is added past those points.

Past a certain point, the accel pump shot is not really needed as the "power piston" takes over when manifold vacuum drops past a certain point. The accel pump is temporary, as the power piston mixture is constant as long as the vacuum is below a certain level. Like 5" hg, which is where most Holley power valves open.

Our '66 Newport 383 had a Stromberg WWC3-262 2bbl carb on it. I liked the (what I considered more modern) design of the carb, when compared to the Carter BBD. My '80 Newport 360 has a 318-size BBD on it, OEM. Not a bad carb, once I learned more about it. Not sure if your WWC is prone to the same issues as the larger WWCs on 383? Does the air cleaner "clamp" onto the carb, rather than having a center carb stud and wing nut?

In the mean time, you might tweak the tune-up settings and see how things go. Maybe a bit more base timing? All the while accumulating $$$ and throttle linkage items for the 4bbl upgrade in the future.

Take care,

CBODY67

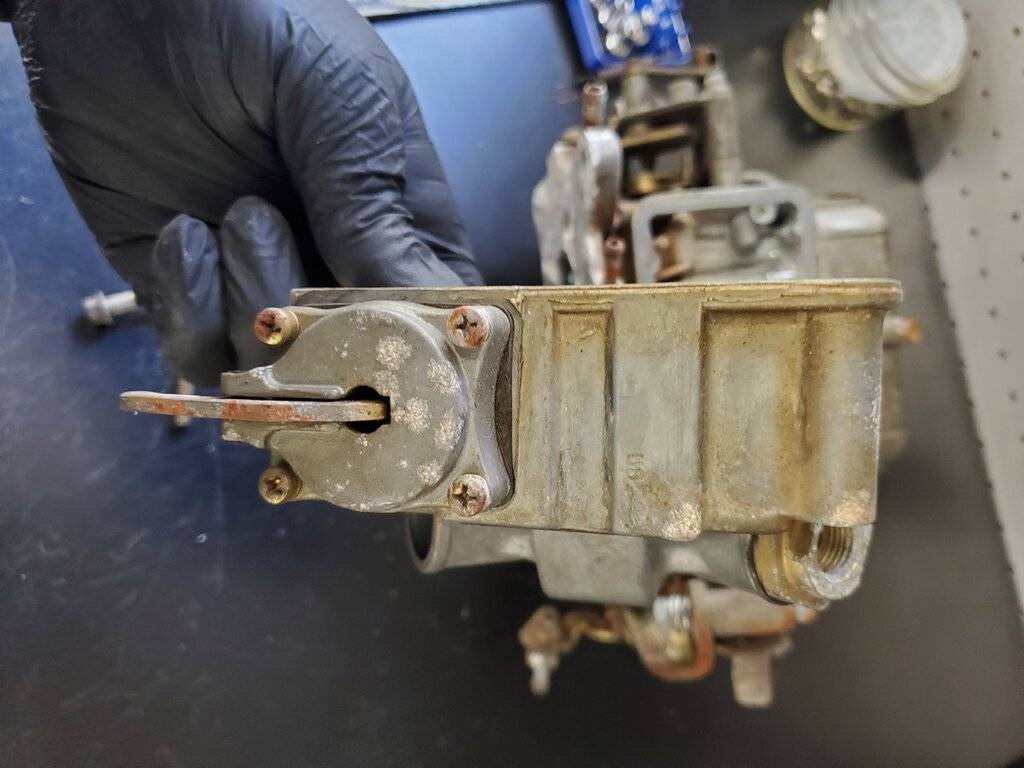

Is that leather on the pump? If so, you can take off the red one (ethenal proof) off an edelbrock as an upgrade. Leather shrinks after awhileOk, ill have to do that in the spring time! I just drove it to my storage hanger before the big storm rolls in tonight and shits a bunch of snow all over us.anything that has a light pedal pressure it stumbles. Taking a turn lightly on the gas, stalls out, (so maybe a bowl float issue there?) As i understand the accel pump is just for the initial "prime" when you are at cruising speeds and step on the gas as if you were passing someone. It gives a "shot" of fuel to the carb so its smooth until the power piston catches up so to speak(picture show power piston on the and accel pump on right with spring. It does not like light pedal pressure.Yes the WW has the air cleaning housing tighten around the air horn, and I've read that it can warp the horn and the **** gets f'd. Is there a way to tell if it wrapped? I am planning on rebuilding the carb that came original to the car when it was first purchased in 1965 and possibly drilling the jets to make them bigger, my father in law knows how to do all that. And the one that sits on there now is a remanned stromberg and I figured ill take that off, see how the one I rebuilt runs and then rebuild the reman one. And if they both suck then I plan on getting a holley 500cfm 2bbl. And selling the strombergs.

View attachment 423396

Thanks for the additional information. On one hand, it sounds like a temporary lean spot which the accel pump is not covering. On the other hand, it could also be that transition slot/throttle plate relationship thing that I mentioned causing a flat spot. Seems like that if more than .040" of the transition slot is below the throttle plates at hot base idle, poor transition (between base idle and when the main system starts working), driveability issues can happen. The HP Books and S-A Designs Holley carb books explain this situation, which is cured by drilling a hole in each of the throttle plates to allow the additional air into the engine at idle (required when wilder-than-stock cams are installed and OEM-spec carbs are used) in order to keep the transition slot and the throttle plates in the desired relationship.

If your best hot idle speed is 700rpm, then the throttle is cracked open more than it was with the stock cam, I suspect. Which is the reason I'm suspecting this might be where the issues are.

I wasn't aware that the clamp system for the air cleaner would warp the air horn. I know that on the larger WWC3 on the B engines, consistent over-torque on the air cleaner wing nut will pull the air cleaner stud (anchored into the air horn) upward and will warp THAT casting upward, right where the rear of the float bowl seals againt the top of the air horn AND where the vacuum passage goes up into the air horn to run the power valve's piston. When that happens, on a cold engine, raw fuel can be sucked from the float bowl into the throttle bores by the choke valve, until it opens up more from initial start-up. Definitely an over-rich situation, from my experiences. Fuel economy drops to about 11-12mpg, even on the highway as the power mixture is "on" all of the time. This was a known issue on the WWC3 Strombergs and the later Holley 2210s. Chrylser did come out with a "bridge kit" for the Holley 2210s, though. The Carter BBDs did not have that issue due to the way the air cleaner stud was anchored.

Using a Holley 2300 2bbl (related to the 4150/4160 Holley 4bbl family) will most probably require some sort of adapter to your (or any Chrysler 2bbl intake) manifold to get it to bolt on. Better to just plan on the 4bbl, I suspect, considering what it would take to make the Holley 2300 work. The Holley 2210 and the B-engine Carter BBD have 1.56" throttle bores and a larger bolt pattern, too.

Enjoy your winter recess from working on cars!

CBODY67

If your best hot idle speed is 700rpm, then the throttle is cracked open more than it was with the stock cam, I suspect. Which is the reason I'm suspecting this might be where the issues are.

I wasn't aware that the clamp system for the air cleaner would warp the air horn. I know that on the larger WWC3 on the B engines, consistent over-torque on the air cleaner wing nut will pull the air cleaner stud (anchored into the air horn) upward and will warp THAT casting upward, right where the rear of the float bowl seals againt the top of the air horn AND where the vacuum passage goes up into the air horn to run the power valve's piston. When that happens, on a cold engine, raw fuel can be sucked from the float bowl into the throttle bores by the choke valve, until it opens up more from initial start-up. Definitely an over-rich situation, from my experiences. Fuel economy drops to about 11-12mpg, even on the highway as the power mixture is "on" all of the time. This was a known issue on the WWC3 Strombergs and the later Holley 2210s. Chrylser did come out with a "bridge kit" for the Holley 2210s, though. The Carter BBDs did not have that issue due to the way the air cleaner stud was anchored.

Using a Holley 2300 2bbl (related to the 4150/4160 Holley 4bbl family) will most probably require some sort of adapter to your (or any Chrysler 2bbl intake) manifold to get it to bolt on. Better to just plan on the 4bbl, I suspect, considering what it would take to make the Holley 2300 work. The Holley 2210 and the B-engine Carter BBD have 1.56" throttle bores and a larger bolt pattern, too.

Enjoy your winter recess from working on cars!

CBODY67

Is that leather on the pump? If so, you can take off the red one (ethenal proof) off an edelbrock as an upgrade. Leather shrinks after awhile

Yessir it is!

Ah I see with the warplanes now. And thank you for all the info.Thanks for the additional information. On one hand, it sounds like a temporary lean spot which the accel pump is not covering. On the other hand, it could also be that transition slot/throttle plate relationship thing that I mentioned causing a flat spot. Seems like that if more than .040" of the transition slot is below the throttle plates at hot base idle, poor transition (between base idle and when the main system starts working), driveability issues can happen. The HP Books and S-A Designs Holley carb books explain this situation, which is cured by drilling a hole in each of the throttle plates to allow the additional air into the engine at idle (required when wilder-than-stock cams are installed and OEM-spec carbs are used) in order to keep the transition slot and the throttle plates in the desired relationship.

If your best hot idle speed is 700rpm, then the throttle is cracked open more than it was with the stock cam, I suspect. Which is the reason I'm suspecting this might be where the issues are.

I wasn't aware that the clamp system for the air cleaner would warp the air horn. I know that on the larger WWC3 on the B engines, consistent over-torque on the air cleaner wing nut will pull the air cleaner stud (anchored into the air horn) upward and will warp THAT casting upward, right where the rear of the float bowl seals againt the top of the air horn AND where the vacuum passage goes up into the air horn to run the power valve's piston. When that happens, on a cold engine, raw fuel can be sucked from the float bowl into the throttle bores by the choke valve, until it opens up more from initial start-up. Definitely an over-rich situation, from my experiences. Fuel economy drops to about 11-12mpg, even on the highway as the power mixture is "on" all of the time. This was a known issue on the WWC3 Strombergs and the later Holley 2210s. Chrylser did come out with a "bridge kit" for the Holley 2210s, though. The Carter BBDs did not have that issue due to the way the air cleaner stud was anchored.

Using a Holley 2300 2bbl (related to the 4150/4160 Holley 4bbl family) will most probably require some sort of adapter to your (or any Chrysler 2bbl intake) manifold to get it to bolt on. Better to just plan on the 4bbl, I suspect, considering what it would take to make the Holley 2300 work. The Holley 2210 and the B-engine Carter BBD have 1.56" throttle bores and a larger bolt pattern, too.

Enjoy your winter recess from working on cars!

CBODY67

66 Monaco 500 365

Member

I had a '60 Phoenix Dart, 318 polly with a factory 4bbl.

I rebuilt the engine and put a larger cam in it (I don't remember the specs)

I tried a Weiand aluminum intake and it KILLED low end torque with little or no improvement on the top, I put the stock intake manifold back on it and it was significantly better.

I would try to find a stock iron 4bbl manifold if possible when you upgrade to 4bbl.

My $.02

I rebuilt the engine and put a larger cam in it (I don't remember the specs)

I tried a Weiand aluminum intake and it KILLED low end torque with little or no improvement on the top, I put the stock intake manifold back on it and it was significantly better.

I would try to find a stock iron 4bbl manifold if possible when you upgrade to 4bbl.

My $.02

Thank you, and yes I can find one but I want to keep the factory 2 bbl on. I'm definitely going to mess around with the original carb, rebuild it and probably drill out the jets to make them bigger just to see. I will eventually upgrade to a 4 bbl intake but I'm going to rebuild the engine again and bor it over .040 and put a 4 inch stoker kit in it.I had a '60 Phoenix Dart, 318 polly with a factory 4bbl.

I rebuilt the engine and put a larger cam in it (I don't remember the specs)

I tried a Weiand aluminum intake and it KILLED low end torque with little or no improvement on the top, I put the stock intake manifold back on it and it was significantly better.

I would try to find a stock iron 4bbl manifold if possible when you upgrade to 4bbl.

My $.02

66 Monaco 500 365

Member

I also ran a stock LA 318 2bbl complete intake on a 360 for a while (California smog BS) and although it idled ok, it didn't run well at part throttle, too lean. jetting up will definitely help. drilling out the accelerator outlet (if it is able to be done) may help, I'm not familiar with that carb.

I hope you can get it sorted.

I hope you can get it sorted.

Thank you! My father in law is pretty good with that stuff and had suggested drilling the jets.I also ran a stock LA 318 2bbl complete intake on a 360 for a while (California smog BS) and although it idled ok, it didn't run well at part throttle, too lean. jetting up will definitely help. drilling out the accelerator outlet (if it is able to be done) may help, I'm not familiar with that carb.

I hope you can get it sorted.

Update on Carb status, I decided to get a Holley 2bbl 500 cfm. I found one on ebay for $165 bought a rebuild kit and cleaned and rebuilt it. She is sitting on top of the stock 2bbl polyhead intake. I changed the 4.5 power valve out for a 10.5 and the jets that came with it are 73s, the squirter is a 28. I have my total timing set at 34 at 3000rpm and inital is set at 15 at about 750 rpm. I've adjusted the idle screws, curb idle, and the accelerator pump to spec. The car idles nice and cruises nice and smooth, however when I am at a stop and I smash into the gas peddle she will stall and when I I'm cruising and step on it there is a slight hesitation/dead spot and then she gets up and goes. My question is should I replace the squirter nozzle to solve the issue? My father in law gave me a 31 squirter nozzle and 76 jets. I tried to advance my timing to 36 at 2500 but it was doing the same thing. Any help or advice would be awesome, I also attached some pictures of the carb before during and after cleaning and rebuild.

Similar threads

- Replies

- 17

- Views

- 1K