I know this is a couple years old, but mine just took longer to rust away. I was originally going to do the repair similar to how you did yours, but after I cut the old one away and started cleaning the surfaces, I stuck a 2x4 up there to see if the bottom of the frame was flat, thats when I got the idea to use a rectangular box beam.

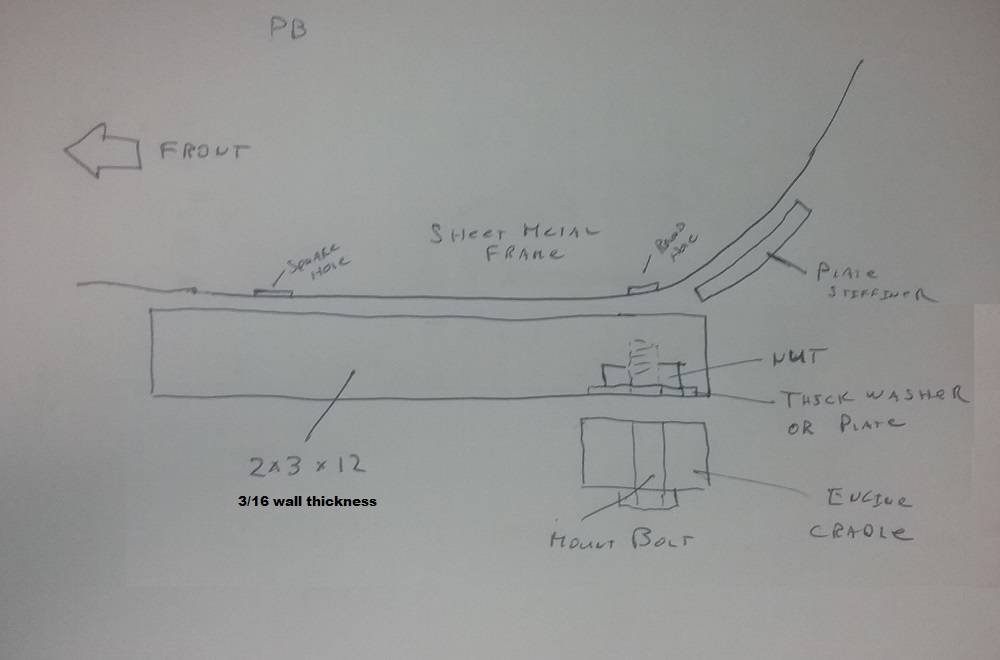

I repaired mine by welding a 2x3x12 box beam to the bottom of the frame. I did a complete writeup on my blog site

TOAD – 2003 Saturn Vue

..

I repaired mine by welding a 2x3x12 box beam to the bottom of the frame. I did a complete writeup on my blog site

TOAD – 2003 Saturn Vue

..