So I believe I’ve located my noise! I de idea to pull the distributor and check its shaft, which was fine and the bushing on the shaft is good and there is no side to side play in the shaft.

I next decided to check the oil pump drive shaft and found some play in the top of the shaft wheee it meshes with the cam; I rotated the engine by hand and found that the oil pump drive shaft “wobbles” and was clipping a bit of casting flash on the inside front of the engine just above the cam shaft front bearing, which is exactly where this frustrating “rub rub rub” noise is.

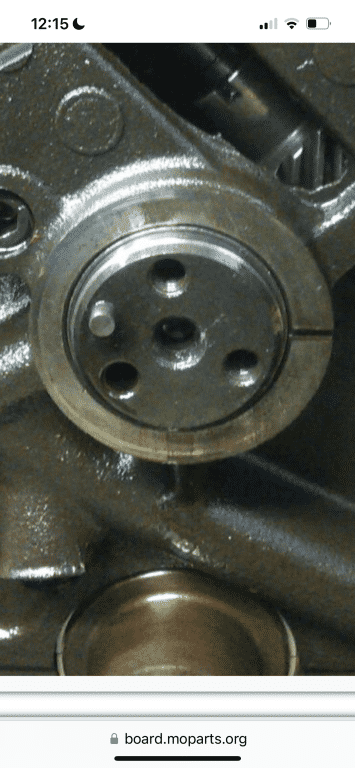

I then marked and removed the oil pump shaft, and it turns out the oil pump driveshaft bushing is completely worn out, and wallowed in an oblong shape. I re installed the shaft half way in and could rotate it in a “wobble” in a 1/2” out of round circle easily, so I’m sure that the top of the shaft is moving up and forward slightly each rotation, and the top of the gear of the oil pump shaft it clipping the end of the one part of the casting shaft, which would definitely lead to a “rub rub rub” sound at the top of the engine, at the top of the timing chain cover area.

I definitely need to fix it and I’m hoping that is the source of my noise!

A buddy had a brand new oil pump drive shaft that he didn’t use in an earlier 440 build so he gave me that. I’m off to my local engine machining shop first thing tomorrow to get a new bushing.

So my only hurdle is how to go about removing the worn out old bushing. I thought I could pull it through the distributor hole with my pilot bushing puller on a slide hammer, but the legs on the pilot puller are just a bit too wide to go through the hole in the bearing.

Has anyone here replaced the oil pump shaft bushing with the engine in the car, and if so how can I go about removing the old one?