Bit of a mistake describing the spark plug situation.

The plugs that were in the engine when it was put into storage 25 years ago were RN12YC. And N12YC. Um, ya. Three were non-resistor. Not sure of the story behind that. They are black. Electrodes are not in bad condition, the non-resistor plugs gap a little more than 35 but not 40, the resistor plugs gap over 40 but not 45.

It now has RN14YC. Every time I've had the engine running, the temp guage has barely got to the cold line on the gauge. I know it's mostly idling, it should be driven I know.

Then I decided to go hi-tech:

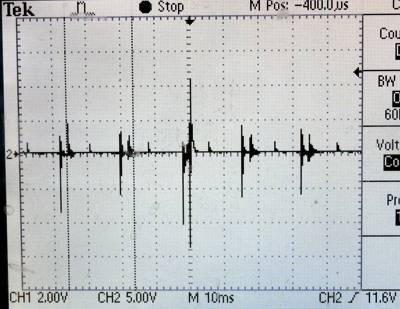

I'm using a scope to look at cylinder 1 plug wire, and I'm also looking at the signal across the primary leads of the coil.

Looking at the traces and going the math, I was coming up with the engine running at 250 rpm. But then I realized - the crank turns twice for every 8 sparks. So the engine was idling at 500 rpm here.

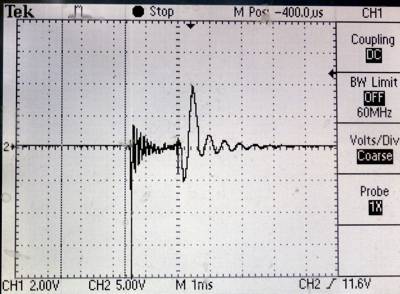

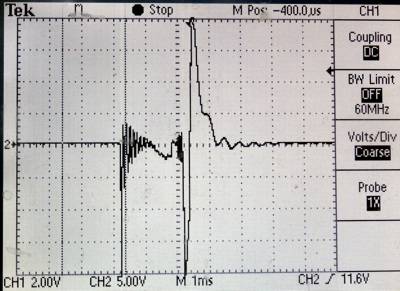

I had 10 turns of wire wrapped around spark-wire 1, but I was seeing a signals for each spark on this wire. Obviously a lot of cross talk, but here's what a weak (cross-talk) signal looks like, vs probably the real spark:

(weak signal, likely cross-talk)

(strong signal, probably the real spark)

In the future, I'll use fewer turns of wire to pick up this signal without the cross-talk.

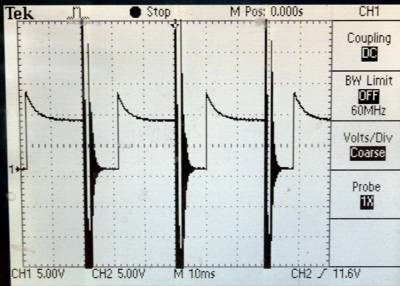

Here's what the coil signal looks like:

Those are 3 consecutive coil charge/discharge cycles. I brought these pictures into a graphics editing program and took some measurements from them, put those into excel and did some math. Those 3 consecutive coil sparks, when converted into instantaneous RPM, work out to 509, 524 and 528 RPM. So there's a lot of timing variability here, where exactly it comes from I don't know.

The ratio of how long the points are open vs closed I can get from that trace, and that does change from 37% to 32%. If 100% = 45 degrees (360 / 8 = 45) then 32% is 14 degrees and 37% is 17 degrees. So my dwell is between 14 and 17 degrees? Am I doing this math right?

The plugs that were in the engine when it was put into storage 25 years ago were RN12YC. And N12YC. Um, ya. Three were non-resistor. Not sure of the story behind that. They are black. Electrodes are not in bad condition, the non-resistor plugs gap a little more than 35 but not 40, the resistor plugs gap over 40 but not 45.

It now has RN14YC. Every time I've had the engine running, the temp guage has barely got to the cold line on the gauge. I know it's mostly idling, it should be driven I know.

Then I decided to go hi-tech:

I'm using a scope to look at cylinder 1 plug wire, and I'm also looking at the signal across the primary leads of the coil.

Looking at the traces and going the math, I was coming up with the engine running at 250 rpm. But then I realized - the crank turns twice for every 8 sparks. So the engine was idling at 500 rpm here.

I had 10 turns of wire wrapped around spark-wire 1, but I was seeing a signals for each spark on this wire. Obviously a lot of cross talk, but here's what a weak (cross-talk) signal looks like, vs probably the real spark:

(weak signal, likely cross-talk)

(strong signal, probably the real spark)

In the future, I'll use fewer turns of wire to pick up this signal without the cross-talk.

Here's what the coil signal looks like:

Those are 3 consecutive coil charge/discharge cycles. I brought these pictures into a graphics editing program and took some measurements from them, put those into excel and did some math. Those 3 consecutive coil sparks, when converted into instantaneous RPM, work out to 509, 524 and 528 RPM. So there's a lot of timing variability here, where exactly it comes from I don't know.

The ratio of how long the points are open vs closed I can get from that trace, and that does change from 37% to 32%. If 100% = 45 degrees (360 / 8 = 45) then 32% is 14 degrees and 37% is 17 degrees. So my dwell is between 14 and 17 degrees? Am I doing this math right?