fury69

New Member

thanks for your answers. meanwhile i assembled the engine again .... put rtv silicon on all the intake-chambers (intake side and head side)

--> still the same

but i was able to run the engine again and get the oilpressure and compression.

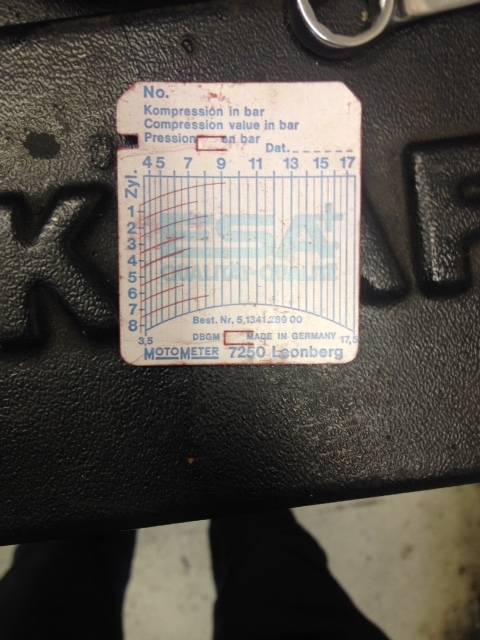

Oilpressure looks fine.... the compression is attached ...

thanks for your input dave: but i can't follow you at this time

what do you mean whit the " front and rear rails"??

is that the place where the rubber or cork gaskets should be installed?

fyi ... as the edelbrock manual says ... i did not use this gaskets, just put a

1/4 inch thick rtv silicon coat on it instead of the seals.

--> still the same

but i was able to run the engine again and get the oilpressure and compression.

Oilpressure looks fine.... the compression is attached ...

thanks for your input dave: but i can't follow you at this time

what do you mean whit the " front and rear rails"??

is that the place where the rubber or cork gaskets should be installed?

fyi ... as the edelbrock manual says ... i did not use this gaskets, just put a

1/4 inch thick rtv silicon coat on it instead of the seals.