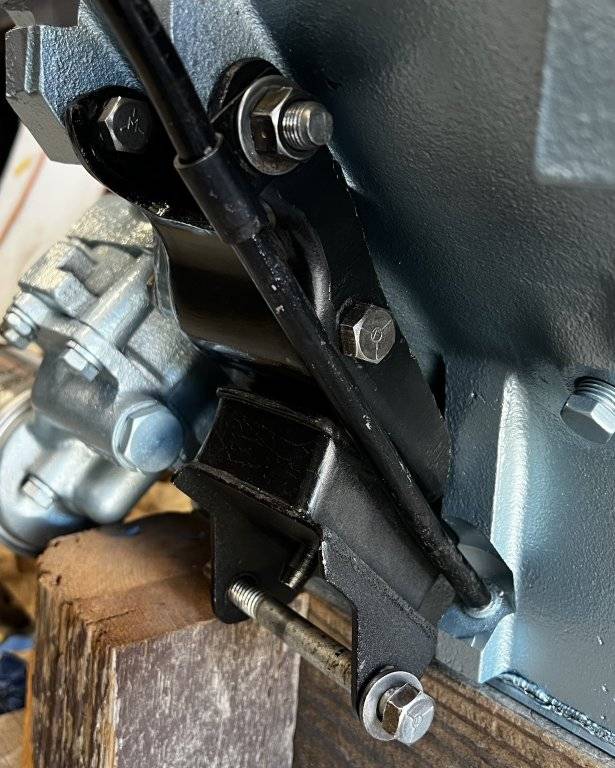

These brackets are basically touching the block… is that really how they’re supposed to be?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor mount question…

- Thread starter Isaiah Estrada

- Start date

lemondana

Active Member

Yep!

1970FuryConv

Old Man with a Hat

Looks OK to me.

Gerald Morris

Senior Member

Lovely! What brand of rubber biscuit did you use? I would add some sort of torque strap on the driver side, as I've separated too many rubber biscuits there which otherwise still had good looking rubber. I used a short bit of 1/4" thick towchain for years after going through 3 biscuits the first summer, then finally found an original Mopar cable from a bloke in this Forum. Some folks use turnbuckles to good effect.

Lovely! What brand of rubber biscuit did you use? I would add some sort of torque strap on the driver side, as I've separated too many rubber biscuits there which otherwise still had good looking rubber. I used a short bit of 1/4" thick towchain for years after going through 3 biscuits the first summer, then finally found an original Mopar cable from a bloke in this Forum. Some folks use turnbuckles to good effect.

Heh, that's a new term for these to me! Gonna steal that ...

To answer your question tho, I'm honestly not sure. I bought them a really long time ago. They are just a generic brand. I paid about $25 for them IIRC. If I was loaded maybe I'd spend the extra cash on those fancy schmancy $200 polyurethane mounts.

See Post 7. With your mount out of the car, you can easily make this mod to the driver's mount and NEVER worry about it again.

strong engine mounts 1969 c body 440

strong engine mounts 1969 c body 440

sixpkrt

Senior Member

- Joined

- Jan 18, 2013

- Messages

- 2,537

- Reaction score

- 7,610

Here are some reference pics from my 440

Gerald Morris

Senior Member

Yowza YOWZA! Ways abound for reinforcing the rubber biscuit. The ONE advice to stick with is this: KEEP IT RUBBER! Solid steel, or polyurethane mounts TRANSMIT ENGINE VIBRATION TO THE FRAME, defeating the purpose of having an "INSULATOR" in the 1st place. I concede, for drag racing, these harder substances outlast rubber, but I don't want those EVIL VIBRATIONS going to my ride.

Putting one or 2 bolts through the biscuit works well for plenty folks. Had I not found the rare, nigh unobtainable cable I'm blessed with, then I would have run the bolts through the biscuit as described in numerous pages and threads. But I stumbled onto the thing, made for Hemi Cudas I reckon, and thank St. Joe and Son for it.

Putting one or 2 bolts through the biscuit works well for plenty folks. Had I not found the rare, nigh unobtainable cable I'm blessed with, then I would have run the bolts through the biscuit as described in numerous pages and threads. But I stumbled onto the thing, made for Hemi Cudas I reckon, and thank St. Joe and Son for it.

See Post 7. With your mount out of the car, you can easily make this mod to the driver's mount and NEVER worry about it again.

strong engine mounts 1969 c body 440

Yowza YOWZA! Ways abound for reinforcing the rubber biscuit. The ONE advice to stick with is this: KEEP IT RUBBER! Solid steel, or polyurethane mounts TRANSMIT ENGINE VIBRATION TO THE FRAME, defeating the purpose of having an "INSULATOR" in the 1st place. I concede, for drag racing, these harder substances outlast rubber, but I don't want those EVIL VIBRATIONS going to my ride.

Putting one or 2 bolts through the biscuit works well for plenty folks. Had I not found the rare, nigh unobtainable cable I'm blessed with, then I would have run the bolts through the biscuit as described in numerous pages and threads. But I stumbled onto the thing, made for Hemi Cudas I reckon, and thank St. Joe and Son for it.

Made the modification today!

Used a nylock to hold it down

Ready for use!

I think the head of your bolt might stop your mount from settling low enough for the through bolt to frame to thread.Made the modification today!

View attachment 558479

View attachment 558480

Used a nylock to hold it down

View attachment 558478

Ready for use!

Try it before you try lifting motor into car.

Gerald Morris

Senior Member

Isaiah, that big hex head will rest on the pad which the mount should lie flat on. Countersink a carriage bolt head a bit, or use a flat allen socketted head. Look at Boyd's pic carefully. The rest of your motor is damned ENVIABLE! NICE!

I was thinking the same thing about that bolt head. That's why some of the mods folks have used countersunk bolts.

If yours will bolt up, you're fine. I filed my heads until there wasn't much there, because a wafer-thin head provides plenty of strength in this application. Also, just checking....you left a little slop in the assembly when you used that nylock nut, correct? I had about a "business card" looseness.

Otherwise, nice tidy job on your mount! And it will NEVER cause trouble again.

If yours will bolt up, you're fine. I filed my heads until there wasn't much there, because a wafer-thin head provides plenty of strength in this application. Also, just checking....you left a little slop in the assembly when you used that nylock nut, correct? I had about a "business card" looseness.

Otherwise, nice tidy job on your mount! And it will NEVER cause trouble again.

I was thinking the same thing about that bolt head. That's why some of the mods folks have used countersunk bolts.

View attachment 558491

If yours will bolt up, you're fine. I filed my heads until there wasn't much there, because a wafer-thin head provides plenty of strength in this application. Also, just checking....you left a little slop in the assembly when you used that nylock nut, correct? I had about a "business card" looseness.

Otherwise, nice tidy job on your mount! And it will NEVER cause trouble again.

Thanks! Do you think I should just grind the head down some more or should I just disassemble and use a countersunk bolt?

I made sure to not tighten the nylock all the way down!

I'd whittle away at the head of the bolt until you can test-fit it into the K mount location. If you can get the long bolt to thread back into the mount, you're good. Yeah, your engine will be 1/8th inch higher on the driver's side due to that thin head, but that's insignificant.

Good-o on the nylock loosey. Your teeth will thank you.

Good-o on the nylock loosey. Your teeth will thank you.

I'd whittle away at the head of the bolt until you can test-fit it into the K mount location. If you can get the long bolt to thread back into the mount, you're good. Yeah, your engine will be 1/8th inch higher on the driver's side due to that thin head, but that's insignificant.

Good-o on the nylock loosey. Your teeth will thank you.

You all are the best! Went countersunk today…

Wow! Look at you and your countersunk bolt!! That is mighty spiffy....and highly effective.

Good workYou all are the best! Went countersunk today…

View attachment 558681

Similar threads

- Replies

- 5

- Views

- 825

- Replies

- 42

- Views

- 7K

- Replies

- 4

- Views

- 681

- Replies

- 24

- Views

- 3K

- Locked

- Replies

- 0

- Views

- 433