OldWarHorse300

Active Member

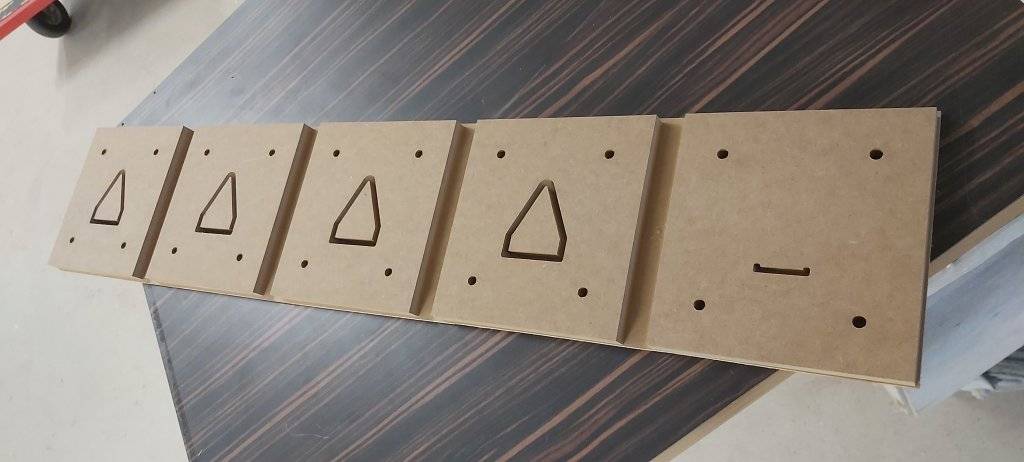

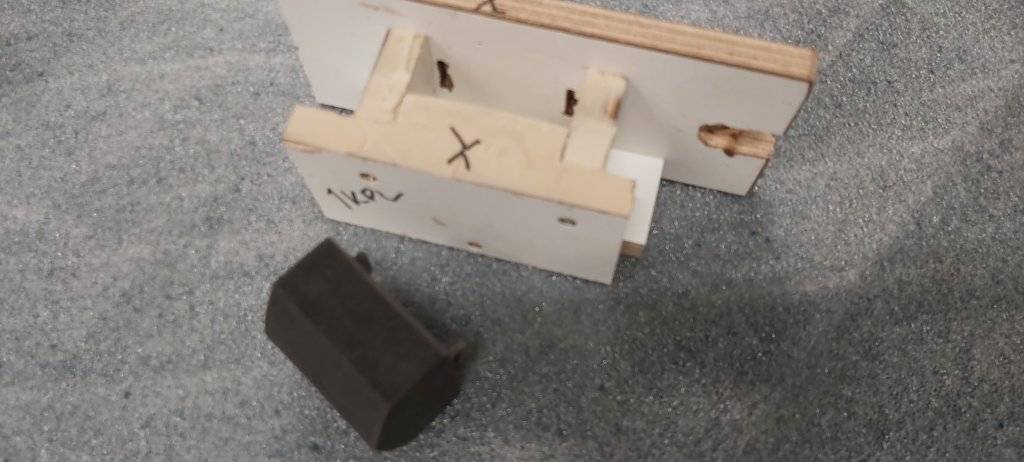

Here's some parts for my -69 Le Baron project. LCA bushings and rear spring isolators are no longer available so I decided to try to make these and some other parts . First I did measuring for 3D modeling, luckily these was simple parts and easy to make with Solidworks . After that it was time for CNC routing , mdf block works for casting mold. Isolators needs two part mold.

Mold surface is painted with 2-part polyuretan topcoat for easy releasing. Metal parts must be sandblasted with coarse sand and clean as possible. Metal needs special primer layer before polyuretan casting. Casting material hardness is A70 , like car tire or maybe little stiffer .

Casting is made by guy who is working with this material. This is very fast 2 component mixing, pot life/ reaction time is only 20 seconds! So there is no time for hesitation..

I'm very happy with a result, parts fits in place nicely.

Regards,

Mika

Mold surface is painted with 2-part polyuretan topcoat for easy releasing. Metal parts must be sandblasted with coarse sand and clean as possible. Metal needs special primer layer before polyuretan casting. Casting material hardness is A70 , like car tire or maybe little stiffer .

Casting is made by guy who is working with this material. This is very fast 2 component mixing, pot life/ reaction time is only 20 seconds! So there is no time for hesitation..

I'm very happy with a result, parts fits in place nicely.

Regards,

Mika