Last December 30th marked the fifth year of my NYB adventure.

Looking back on my original thread, I’m humbled by all the help received from fellow members. I also realized, how much we’ve done and learned in that time.

So… I’ve been mentioning, on my other main thread, that I would replace the original working Lean Burn ignition with its logical “next step” of development had Chrysler taken it to fuel injection….Namely: the Holley Sniper. There are other systems out there and I did look at them but settled on the Holley system having seen it on this site (and others) being installed to excellent effect.

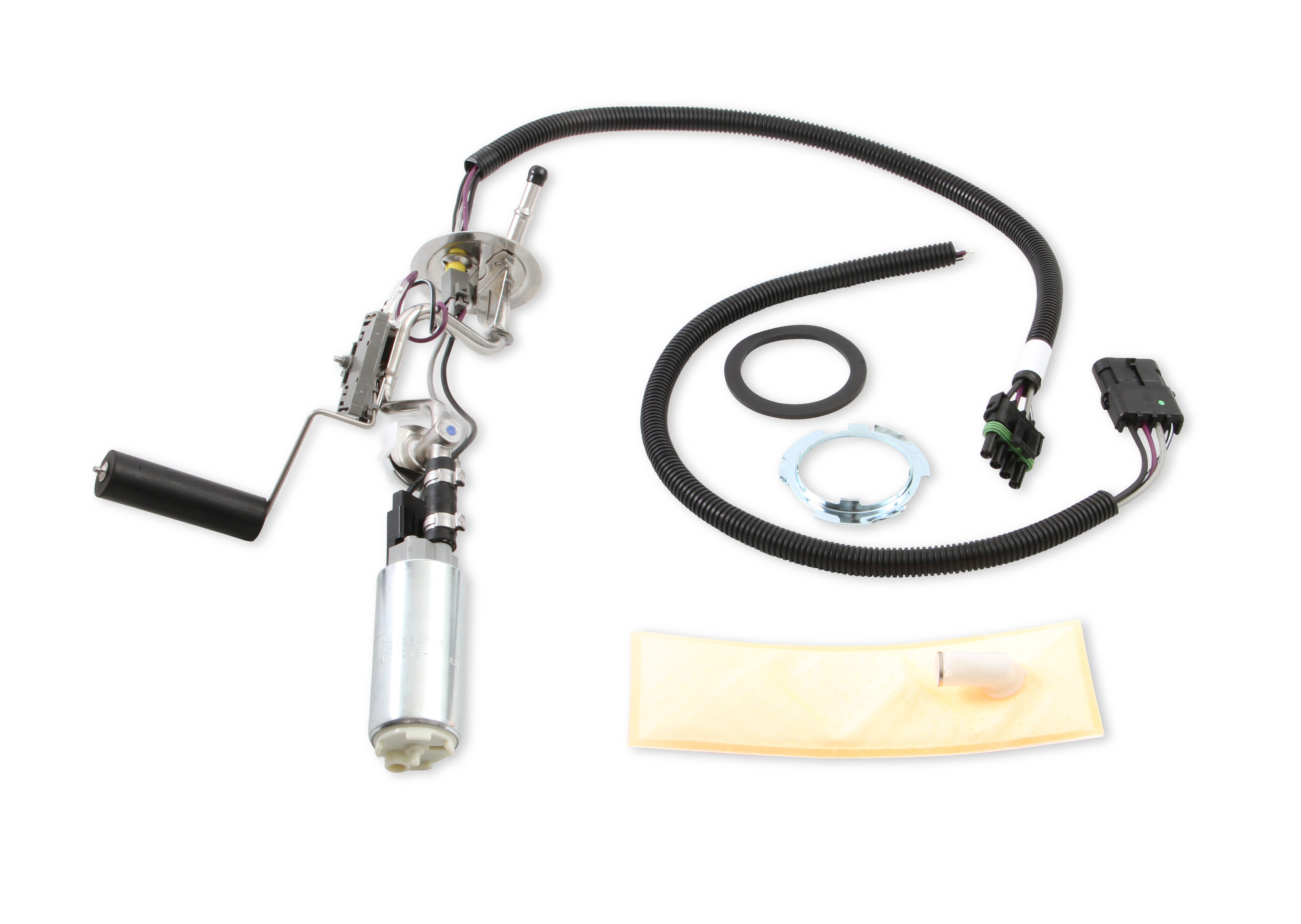

Specifically, I chose the Holley Sniper 550-511D kit which included an in-tank pump to provide the pressurized fuel needed.

Having restored a 76 and then a 77 Cadillac Seville, I knew a thing or two about antique and simple fuel injection systems. Both these cars had external pumps which then fed pressurized fuel (similar to Mercedes). Both systems exposed the pumps to problems with weathering exposure, (and damage) which I did not want to do. I figured we could set up the in-tank pump so I could access it through the trunk if I worked it carefully.

So that’s where we will start. Let the fun begin!

Partial kit contents

El pumpo

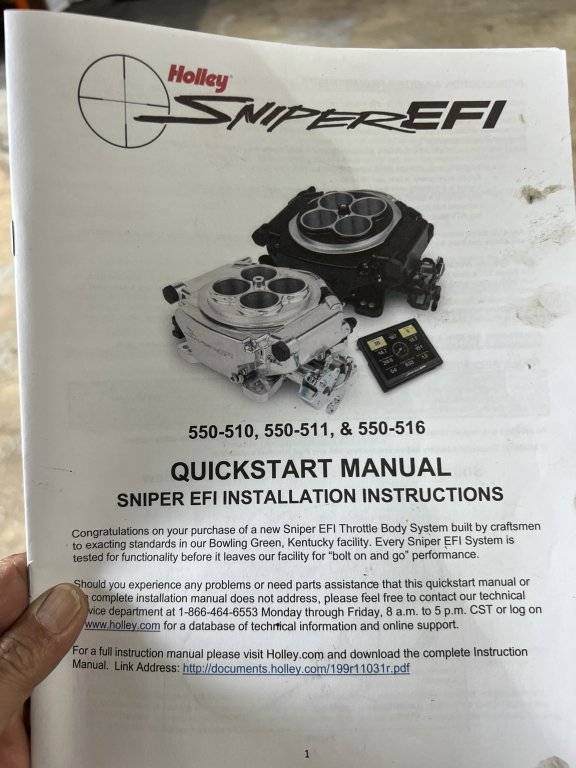

Great instructions that even a moron like me can understand with a few re-readings

Tank out…. No big deal. Hardest part was dumping 20 plus gallons of premium. I put most of it in my wagon and gave the guys in the shop the rest with a “Who wants it “ offer…. It didn’t last.

Where we decided to put the pump. Commando’s suggestion. Thanks.

The kit…. Black because the Thermoquad was mostly black…. Not that anyone will see it under the air cleaner.

Well,at least, I found out why the sender was getting wonky… gloat was filled with gas. New sender with float on the way. No need to have to go through this again any time soon…. I hope!

Will need to fabricate a cover over the pump as it will protrude into the trunk. Fuel line will be routed to the front (I think, still working that out in my head) to then intercept the original hard fuel line to the engine bay

First test fit on the engine… linkage will need some McGivering to get it to work but nothing too difficult to solve. At least it’s on the correct side!

Looking back on my original thread, I’m humbled by all the help received from fellow members. I also realized, how much we’ve done and learned in that time.

So… I’ve been mentioning, on my other main thread, that I would replace the original working Lean Burn ignition with its logical “next step” of development had Chrysler taken it to fuel injection….Namely: the Holley Sniper. There are other systems out there and I did look at them but settled on the Holley system having seen it on this site (and others) being installed to excellent effect.

Specifically, I chose the Holley Sniper 550-511D kit which included an in-tank pump to provide the pressurized fuel needed.

Having restored a 76 and then a 77 Cadillac Seville, I knew a thing or two about antique and simple fuel injection systems. Both these cars had external pumps which then fed pressurized fuel (similar to Mercedes). Both systems exposed the pumps to problems with weathering exposure, (and damage) which I did not want to do. I figured we could set up the in-tank pump so I could access it through the trunk if I worked it carefully.

So that’s where we will start. Let the fun begin!

Partial kit contents

El pumpo

Great instructions that even a moron like me can understand with a few re-readings

Tank out…. No big deal. Hardest part was dumping 20 plus gallons of premium. I put most of it in my wagon and gave the guys in the shop the rest with a “Who wants it “ offer…. It didn’t last.

Where we decided to put the pump. Commando’s suggestion. Thanks.

The kit…. Black because the Thermoquad was mostly black…. Not that anyone will see it under the air cleaner.

Well,at least, I found out why the sender was getting wonky… gloat was filled with gas. New sender with float on the way. No need to have to go through this again any time soon…. I hope!

Will need to fabricate a cover over the pump as it will protrude into the trunk. Fuel line will be routed to the front (I think, still working that out in my head) to then intercept the original hard fuel line to the engine bay

First test fit on the engine… linkage will need some McGivering to get it to work but nothing too difficult to solve. At least it’s on the correct side!

Last edited: