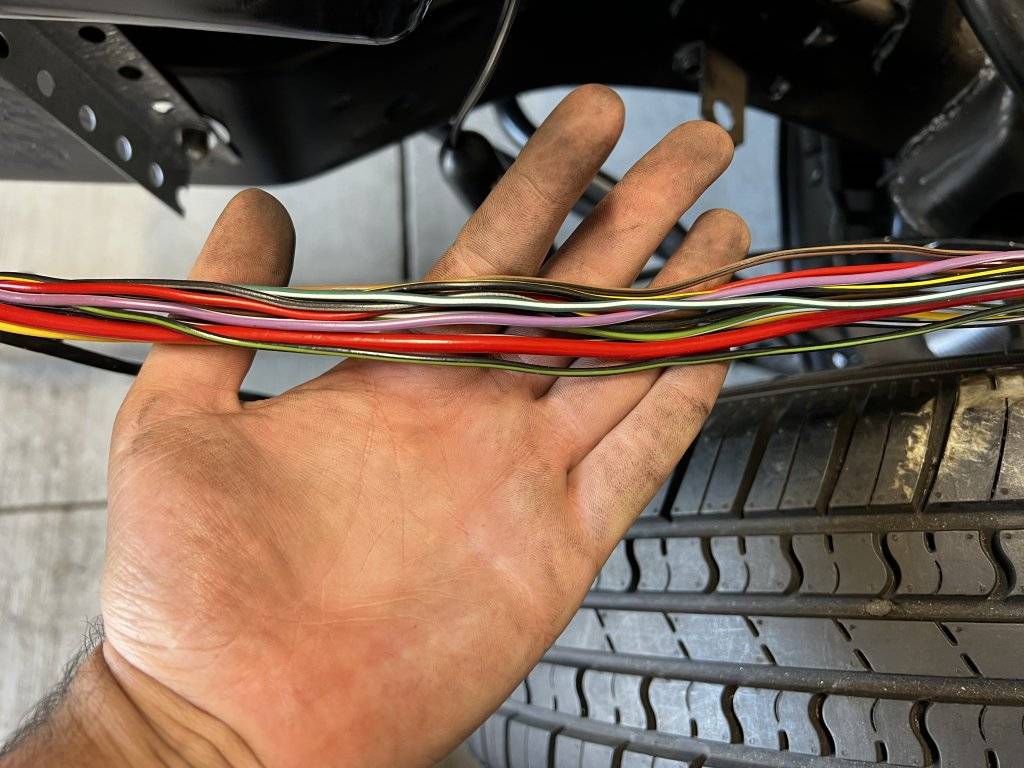

Began to tear into the factory wiring harness of the 68. Amazingly the rats didn’t chew it up, and the tape loom, although crunchy was still intact. I guess I shouldn’t be surprised, but I am - this wire looks BRAND new for its age.

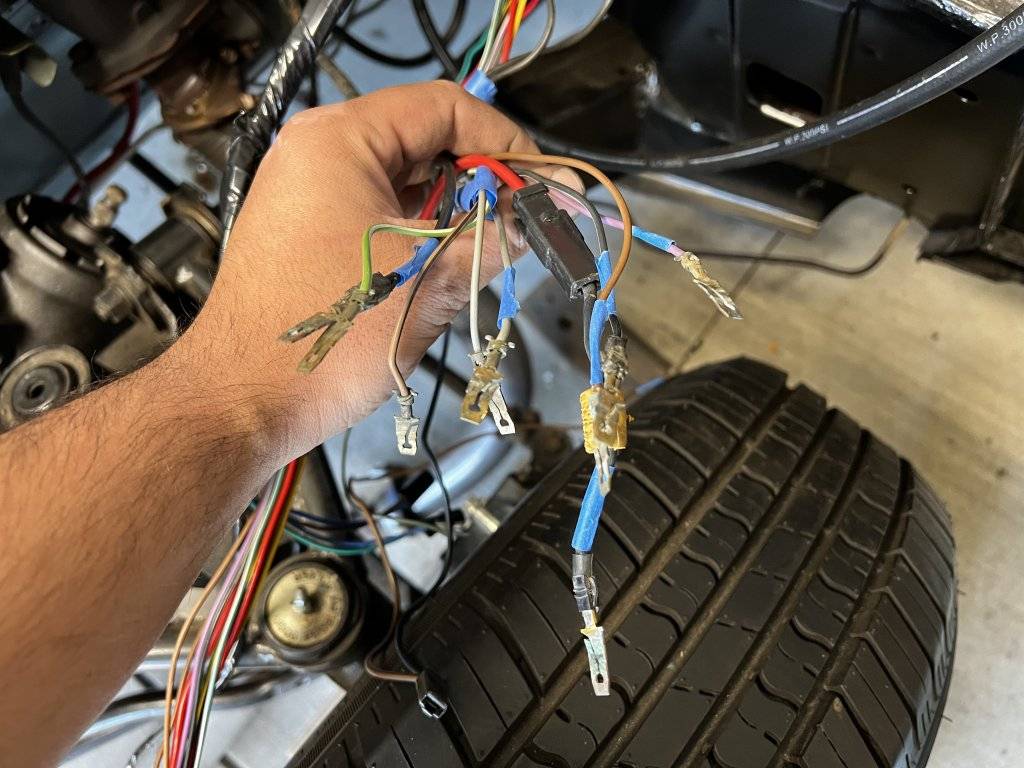

Now to replace all the blade connectors and install them into a new bulkhead. Will be bypassing the ammeter along the way and adding a new headlight relay harness into the mix and then I’ll tidy it all up with new looms.

I started a new job recently and it’s a true blessing. Full time, benefits, and EXCELLENT pay. Only downside (for now) is I’m training on 1st shift (8-4) before going to my graveyard. Sure graveyard isn’t ideal but the way I see it, get off at 8 - sleep for a few hours and wake up around 12, I’ll have a lot of my day to work on my own projects and as long as I can sleep for about 2-3 hours before work at midnight I’ll be fine. Worked for me at my previous job at least!

As you know I’ve been looking at a 62 Chrysler. Still confident I’ll end up bringing it home. Even if I don’t, I’ve still gathered lots of really cool parts for one.

My latest score are these awesome 4 bolt valve covers for that 413

I’m glad to at least be farther along on the 68 than I had been previously. Today was my first day back in about 3 weeks since I started the job. Hard to make it out to the next town over after work!

All that’s left is to rebuild the heater box, and install the dash and she’d be “turnkey” and ready to move under her own power. Seats are almost done, floors are patched up. Just needs POR-15 all over the inside, insulation and then my new carpet, headliner, seats and door panels. Trying hard to not let myself get down with this car. It’s going to be worth it someday!

Now to replace all the blade connectors and install them into a new bulkhead. Will be bypassing the ammeter along the way and adding a new headlight relay harness into the mix and then I’ll tidy it all up with new looms.

I started a new job recently and it’s a true blessing. Full time, benefits, and EXCELLENT pay. Only downside (for now) is I’m training on 1st shift (8-4) before going to my graveyard. Sure graveyard isn’t ideal but the way I see it, get off at 8 - sleep for a few hours and wake up around 12, I’ll have a lot of my day to work on my own projects and as long as I can sleep for about 2-3 hours before work at midnight I’ll be fine. Worked for me at my previous job at least!

As you know I’ve been looking at a 62 Chrysler. Still confident I’ll end up bringing it home. Even if I don’t, I’ve still gathered lots of really cool parts for one.

My latest score are these awesome 4 bolt valve covers for that 413

I’m glad to at least be farther along on the 68 than I had been previously. Today was my first day back in about 3 weeks since I started the job. Hard to make it out to the next town over after work!

All that’s left is to rebuild the heater box, and install the dash and she’d be “turnkey” and ready to move under her own power. Seats are almost done, floors are patched up. Just needs POR-15 all over the inside, insulation and then my new carpet, headliner, seats and door panels. Trying hard to not let myself get down with this car. It’s going to be worth it someday!