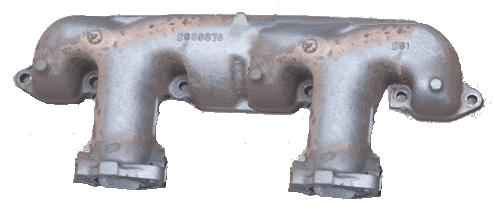

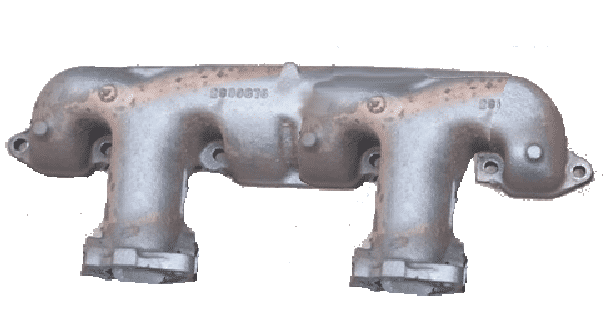

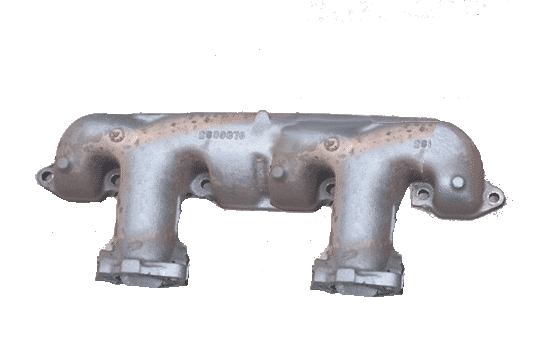

This was just a quick mock-up of an idea I had of taking two sets of manifolds, cutting them and welding them into a dual-outlet setup. Why? Better flow than stock w/o the headaches and noise of headers...maybe. And to be unique and different  Would require some custom piping of course. Could neck them down to one pipe right off the manifold, run them back to a y-pipe to combine them or run two 2" pipes per side all the way back. I have to wonder what that would even sound like, might be interesting!

Would require some custom piping of course. Could neck them down to one pipe right off the manifold, run them back to a y-pipe to combine them or run two 2" pipes per side all the way back. I have to wonder what that would even sound like, might be interesting!

I realize because of the firing order the flow out each of the 4 outlets wouldn't be perfectly balanced. I also wonder what the pros/cons are of leaving the passage between the pairs open vs. welding it shut.

Just another one of hair-brained ideas that popped into my head...

I realize because of the firing order the flow out each of the 4 outlets wouldn't be perfectly balanced. I also wonder what the pros/cons are of leaving the passage between the pairs open vs. welding it shut.

Just another one of hair-brained ideas that popped into my head...