A bit late if your compressor is already installed, but you should make sure the rebuilt unit has the spring and rubber check ball. The last couple of re-mans I went through did not. They are part of the oil system.

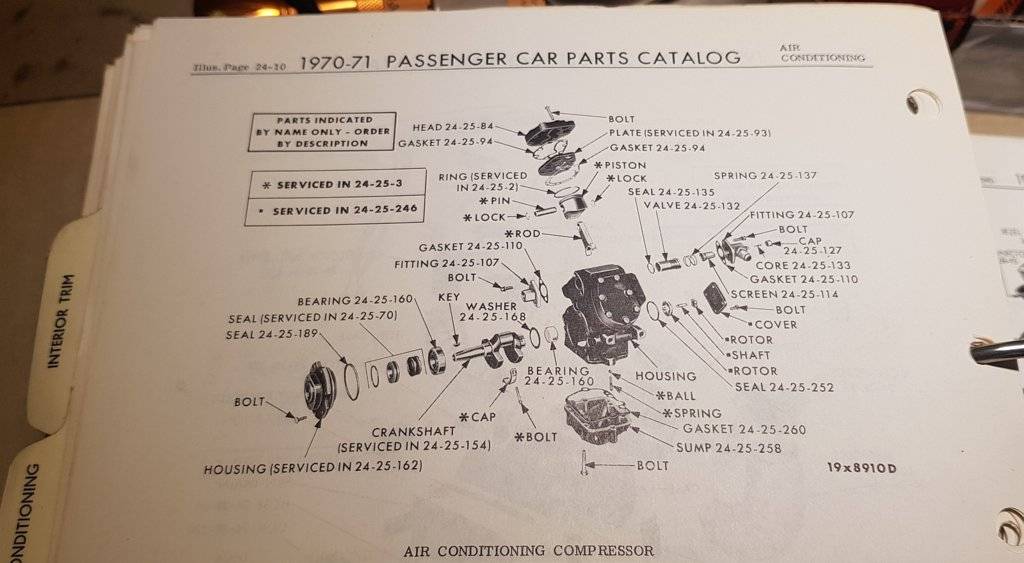

Yep, and that's NOT GOOD. But note that later compressors DID NOT use the ball and spring, and there's no passage for it in the crankcase (see pic below). I think I discussed that in the link above, and maybe in some other thread.

My problems were:

1. Crud stuck to the inside of the sump. It was baked on, and thus minor, but still worrisome.

2. No checkball and spring. I fussed to Four Seasons and a tech there sent me a kit with a steel ball.

3. Once installed and charged, my gas seal wasn't even close to being installed correctly. Just WTF are they rebuilding with these things? The paint job, I guess.

Here's where the checkball and spring go. If there's no passage at this location, you have a newer pump system so no worries.

This is where dye comes in VERY handy....looking for leaks. My gas seal was leaking immediately after charging and running the system. Never had a chance. I bought a $10 aftermarket seal kit from AutoZone and that solved the problem.

And finally, a compressor crankcase with NO checkball and spring. See the red dot on the gasket surface? That's where it's "not".