Last year when I finished putting my car together I got a Quick Trick Alignment system. I figured that two trips to an alignment shop would pay for it. Plus most don’t know how to do it anyway. I did the first alignment last year. Now that I have a couple of thousand miles on it I figured my new rubber bushings have settled in. I will go through the whole process and talk about the Pro’s and cons of the quick trick system as I go. Start with a flat work area. No hoist yet.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

‘68 Polara Alignment by the book

- Thread starter HWYCRZR

- Start date

Before I get the alignment kit out I will start with the basic set up.

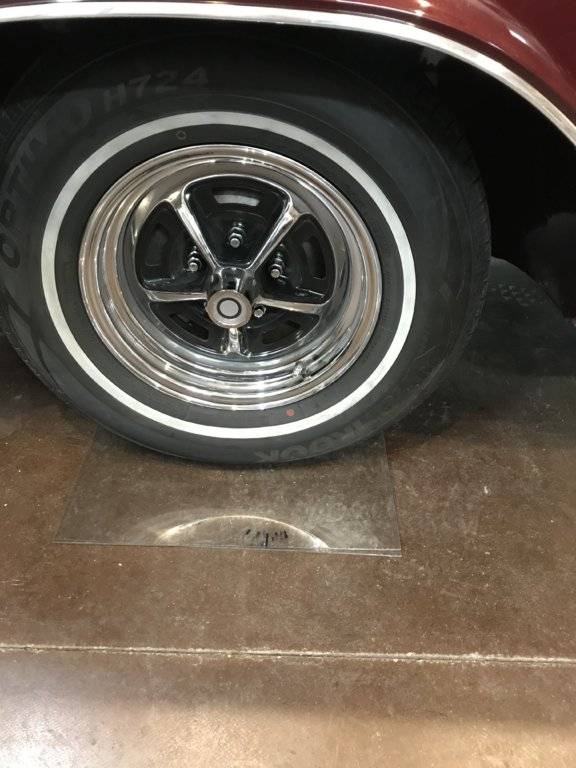

I rotated the tires first. At 2000 miles they really didn’t need it yet, but wanted to check for any wear. The Hankook’s still look new. No scuffing that I could see. Alignment must have been ok.

Check all the air pressures and make sure all are even or your alignment may be off.

Full tank of fuel, empty trunk except spare tire.

To keep the front tires free and able to move when aligning I used two 1/8 pieces of plexiglass with a shot of oil in between. This allows the tires to turn without binding. If I really want to be accurate I would put 1/4” under the rear tires as well. I am not sure my gauges are that accurate.

This is your basic prep. Now you are ready to start.

I rotated the tires first. At 2000 miles they really didn’t need it yet, but wanted to check for any wear. The Hankook’s still look new. No scuffing that I could see. Alignment must have been ok.

Check all the air pressures and make sure all are even or your alignment may be off.

Full tank of fuel, empty trunk except spare tire.

To keep the front tires free and able to move when aligning I used two 1/8 pieces of plexiglass with a shot of oil in between. This allows the tires to turn without binding. If I really want to be accurate I would put 1/4” under the rear tires as well. I am not sure my gauges are that accurate.

This is your basic prep. Now you are ready to start.

First step

Make sure your steering wheel is centered. If your tires are turned or way off you may want to check for tie rod or steering link damage. Or the last guy that did the alignment didn’t know what he was doing. Clamp your steering wheel in the center ( so it doesn’t turn) then turn your steering rods to get your wheels relatively straight before you start. They don’t have to be perfect at this stage. You will fine tune when you check your toe-in in the last step.

Make sure your steering wheel is centered. If your tires are turned or way off you may want to check for tie rod or steering link damage. Or the last guy that did the alignment didn’t know what he was doing. Clamp your steering wheel in the center ( so it doesn’t turn) then turn your steering rods to get your wheels relatively straight before you start. They don’t have to be perfect at this stage. You will fine tune when you check your toe-in in the last step.

Hey Kids before you do anything else get your Service manual out and turn to Section 2. Front Suspension and Steering Linkage. It has things you need.

Suspension height.

This is your first check or adjustment. It seems I had a little settling on the driver’s side. As it was a little low. (Maybe it is just my fat ***). Either last year when I set it, the bushings were all still stiff and new and maybe binding. Or I screwed up.

Any way jounce all 4 corners compressing the suspension 3 or 4 times releasing when its at the bottom.

If it keeps bouncing you need new shocks.

Ride height on my ‘68 Polara is 1-1/8” + - 1/8”. Don’t be alarmed that is not the distance to the ground but the difference in height between the bottom of the adjusting blade and the bottom of the ball joint housing.

In my case I had to add an extra 1/4” as the ball joint measurement because of the plexiglass slides. The adjusting blade measurement needs to be 1-1/8” higher than the bottom of the ballpoint.

Do one side first and then go to the next side. To raise turn the adjusting bolt clockwise. To lower turn counterclockwise. My measurement was about 3/4 of an inch too low.

Don’t mind the bugs. I guess I didn’t crawl all the way under and scrub them off.

Suspension height.

This is your first check or adjustment. It seems I had a little settling on the driver’s side. As it was a little low. (Maybe it is just my fat ***). Either last year when I set it, the bushings were all still stiff and new and maybe binding. Or I screwed up.

Any way jounce all 4 corners compressing the suspension 3 or 4 times releasing when its at the bottom.

If it keeps bouncing you need new shocks.

Ride height on my ‘68 Polara is 1-1/8” + - 1/8”. Don’t be alarmed that is not the distance to the ground but the difference in height between the bottom of the adjusting blade and the bottom of the ball joint housing.

In my case I had to add an extra 1/4” as the ball joint measurement because of the plexiglass slides. The adjusting blade measurement needs to be 1-1/8” higher than the bottom of the ballpoint.

Do one side first and then go to the next side. To raise turn the adjusting bolt clockwise. To lower turn counterclockwise. My measurement was about 3/4 of an inch too low.

Don’t mind the bugs. I guess I didn’t crawl all the way under and scrub them off.

Last edited:

I love this, and will be looking into it, I've always had a rack where I've worked, but if I don't have to drag my own stuff in, that's would be great.

Nick

Nick

The rack would be great for height adjustment. Thankfully I have long arms. I have to lay under the front of the car and reach in. I cold gain about 3” if I put it on the dollies to adjust the height. Someday a lift.I love this, and will be looking into it, I've always had a rack where I've worked, but if I don't have to drag my own stuff in, that's would be great.

Nick

Tomorrow I will tackle the rest of the alignment.

Remember this: don’t adjust height with the front tires on the ground. Jack the front up to take the weight off the tires before turning the adjusting bolts.

It puts more load on the threads and they can gall or strip.

It puts more load on the threads and they can gall or strip.

Last edited:

Is that to make it a bit easier to turn the adjusting bolt? Or a reason to let the jack down quickly so you don't have to bounce the front end (to settle it) before taking the height reading? In any event, having the correct front ride height in specs is important.

GREAT looking car! Thanks for the thread.

CBODY67

GREAT looking car! Thanks for the thread.

CBODY67

Thanks for the tip. The service manual doesn’t outline this. Also I forget that not everyone is starting with clean bolts and adjusting blocks. It is key to make sure your threads are well lubricated and clean to prevent getting dirt and crap that causes the galling in your adjusting block. A little shot of lubricant where the bolt pushes the cam up also helps.Remember this: don’t adjust height with the front tires on the ground. Jack the front up to take the weight off the tires before turning the adjusting bolts.

It puts more load on the threads and they can gall or strip.

Not sure the wheels need to be all the way off the ground but a floor jack under the center cross member to take some weight off the torsion bar’s also help. If you can easily turn the bolt with a normal length 1/2 drive ratchet (12” long), you shouldn’t be causing any damage. If you have to use a longer bar or impact, don’t. You will screw something up.

Just make sure you give the body a couple of extra jounces when you do set it down before measuring.

PH27L7

Well-Known Member

If you don't have the oiled plexiglass, a couple layers of wax paper works great.

Time to get my Alignment pack off the wall.

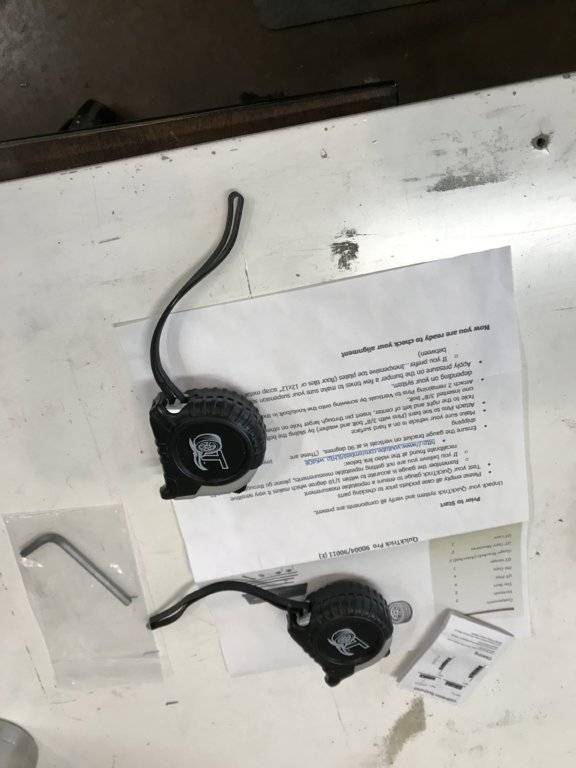

I have no affiliation with Quick Trick. I bought this set when they had a 10 or 15 % sale going on.

It is very simple, and maybe a little over priced for what you get, but a couple trips to the alignment shop or a replacement of a bad tire due to improper alignment will pay for it. Plus I am an extreme do it yourselfer and like tools.

They offer different size kits, and now have upgraded to an aluminum set that in my opinion holds the level better for the camber measurement.

The set I purchased included the brackets, two tape measures (for toe in), one digital gauge and a case.

It didn’t come with instructions but they have a 12 page PDF that you can download along with numerous YouTube videos to watch.

I believe mine is Model QuickTrick Pro 9004/90011.

It is for 13-18” wheels. They obviously have other sizes as well.

I did go on Amazon and get another digital gauge so I could have one for each side. Same gauge as in the kit.

I have no affiliation with Quick Trick. I bought this set when they had a 10 or 15 % sale going on.

It is very simple, and maybe a little over priced for what you get, but a couple trips to the alignment shop or a replacement of a bad tire due to improper alignment will pay for it. Plus I am an extreme do it yourselfer and like tools.

They offer different size kits, and now have upgraded to an aluminum set that in my opinion holds the level better for the camber measurement.

The set I purchased included the brackets, two tape measures (for toe in), one digital gauge and a case.

It didn’t come with instructions but they have a 12 page PDF that you can download along with numerous YouTube videos to watch.

I believe mine is Model QuickTrick Pro 9004/90011.

It is for 13-18” wheels. They obviously have other sizes as well.

I did go on Amazon and get another digital gauge so I could have one for each side. Same gauge as in the kit.

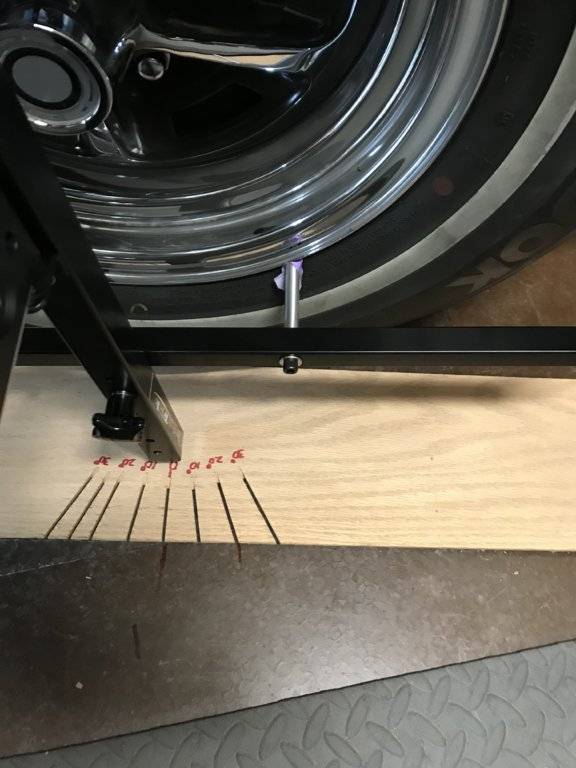

For the setup on the wheel you want everything centered and a plumb as you can get it. I am sure there is room for some error, but I tend to be a perfectionist when it comes to some measurements.

I also used my miter saw to make a protractor so I know where 20 degrees is when checking caster.

I also used my miter saw to make a protractor so I know where 20 degrees is when checking caster.

Alignment order.

Tire inflation

Ride height

Caster Angle

Camber

Toe-in

Caster is the fore and aft angle between your upper and lower ball joints (steering axis). Positive caster is when the top is angled towards the rear.

On our old Mopar’s with manual steering the spec is 0 degrees to -1 degree. This makes steering a little easier. For Power Steering, our cars already steer pretty easily, so the spec is a positive 1/4 - 1-1/4 degrees with less than 3/4 degrees between sides (‘68 Dodge Polara specs).

To measure caster , make sure your vertical bar on the alignment frame is vertical (fore and aft). Put the gauge on the Horizontal tab and turn your tires 20 degrees. Zero your gauge and then steer 20 degrees past center in the opposite direction. Read your gauge and multiply by 1.5. This tells you your Caster . I do this a couple of times for accuracy. If each measurement is the same or within .10 of a degree (level accuracy). Do the calculation and go to the next side.

My left was .4 degrees x 1.5= .6 degrees or about 5/8 degrees

My right was between .4 and .5 each time so I took the average. .45 x 1.5= .675 degrees or close to 11/16 degrees.

Both sides were in spec and well within 3/4 of a degree of each other. If the caster is out it gets a little tricky with the adjusting cams, but can be done. In reality the cams are adjusting both at the same time. I will get into that on my next post and after I eat some lunch.

Tire inflation

Ride height

Caster Angle

Camber

Toe-in

Caster is the fore and aft angle between your upper and lower ball joints (steering axis). Positive caster is when the top is angled towards the rear.

On our old Mopar’s with manual steering the spec is 0 degrees to -1 degree. This makes steering a little easier. For Power Steering, our cars already steer pretty easily, so the spec is a positive 1/4 - 1-1/4 degrees with less than 3/4 degrees between sides (‘68 Dodge Polara specs).

To measure caster , make sure your vertical bar on the alignment frame is vertical (fore and aft). Put the gauge on the Horizontal tab and turn your tires 20 degrees. Zero your gauge and then steer 20 degrees past center in the opposite direction. Read your gauge and multiply by 1.5. This tells you your Caster . I do this a couple of times for accuracy. If each measurement is the same or within .10 of a degree (level accuracy). Do the calculation and go to the next side.

My left was .4 degrees x 1.5= .6 degrees or about 5/8 degrees

My right was between .4 and .5 each time so I took the average. .45 x 1.5= .675 degrees or close to 11/16 degrees.

Both sides were in spec and well within 3/4 of a degree of each other. If the caster is out it gets a little tricky with the adjusting cams, but can be done. In reality the cams are adjusting both at the same time. I will get into that on my next post and after I eat some lunch.

Last edited:

Adjusting caster with the Mopar eccentric cam system. The service manual doesn’t explain this at all. They just say adjust the Camber and Caster using the Cam bolts.

The cam bolts hold the upper control arm in position with the frame. The eccentric washers on the cam bolts and bushings change the alignment when rotated.

For maximum positive caster, you want the front cam bolt turned so the bolt is on the top side of the eccentric washer and the rear cam bolt turned so it is on the bottom of the eccentric washer. This is the maximum amount of positive caster. Remember any time you move these bolts within the eccentric circle you are also changing your camber.

For close to zero or negative caster you would want to turn your front cam bolts so they are at the bottom of your eccentric washer and the rear cam bolt is rotated towards the top of your washer. This tilts the Control Arm forward. You should never realistically be at these extremes, but somewhere in the middle. If you jack the back end up to get more forward take you can adjust the caster more towards the positive end to account for that.

However based on experience in high school there isn’t much caster adjustment to go too high. You quickly run out of positive caster and go negative. Talk about quick steering. It was all I could do to keep it between the lines until I removed one of my “helper” springs I added to the rear. Up next going 3d to accommodate Caster and camber. It can be done.

The cam bolts hold the upper control arm in position with the frame. The eccentric washers on the cam bolts and bushings change the alignment when rotated.

For maximum positive caster, you want the front cam bolt turned so the bolt is on the top side of the eccentric washer and the rear cam bolt turned so it is on the bottom of the eccentric washer. This is the maximum amount of positive caster. Remember any time you move these bolts within the eccentric circle you are also changing your camber.

For close to zero or negative caster you would want to turn your front cam bolts so they are at the bottom of your eccentric washer and the rear cam bolt is rotated towards the top of your washer. This tilts the Control Arm forward. You should never realistically be at these extremes, but somewhere in the middle. If you jack the back end up to get more forward take you can adjust the caster more towards the positive end to account for that.

However based on experience in high school there isn’t much caster adjustment to go too high. You quickly run out of positive caster and go negative. Talk about quick steering. It was all I could do to keep it between the lines until I removed one of my “helper” springs I added to the rear. Up next going 3d to accommodate Caster and camber. It can be done.

Last edited:

When setting your caster try not to mess up your camber too bad. you can usually do this by turning the bolts and eccentric washers in opposite directions. If you turn the front bolt clockwise turn the rear so the eccentric washer goes in the opposite direction the same amount. (The bolt heads are inserted from the outer side in opposing directions so if you put your ratchet head on the rear it will turn the rear opposite). This should adjust caster without affecting the camber too much.

Last edited:

Checking camber

Positive camber is where the top of the wheel leans out, negative camber is where the top of the wheel leans in.

Left side at +.5 degrees. Spec says +1/4 (.25) to +3/4 (.75) +1/2 degree preferred. So right on.

Right side at + .2 spec says 0 to + 1/2 (.5) with+ 1/4 (.25) preferred , so should be good. 1/10 of a degree is less than a 1/32 of movement at the end of the level. It doesn’t take much to change.

So the good news is I don’t have to re-adjust. And it held from last year.

Any, if I was to adjust without messing up my camber, I would want to make sure I was turning the eccentric washers in the same direction, the same amount. To get more positive caster I would turn them so the eccentric washers would push the bolts towards the outside of car. To get more negative camber you would turn the bolts and eccentric washers so the bolts go in towards the engine pulling the upper control arm in.

zero level on the floor to take into account any floor angle.

Positive camber is where the top of the wheel leans out, negative camber is where the top of the wheel leans in.

Left side at +.5 degrees. Spec says +1/4 (.25) to +3/4 (.75) +1/2 degree preferred. So right on.

Right side at + .2 spec says 0 to + 1/2 (.5) with+ 1/4 (.25) preferred , so should be good. 1/10 of a degree is less than a 1/32 of movement at the end of the level. It doesn’t take much to change.

So the good news is I don’t have to re-adjust. And it held from last year.

Any, if I was to adjust without messing up my camber, I would want to make sure I was turning the eccentric washers in the same direction, the same amount. To get more positive caster I would turn them so the eccentric washers would push the bolts towards the outside of car. To get more negative camber you would turn the bolts and eccentric washers so the bolts go in towards the engine pulling the upper control arm in.

zero level on the floor to take into account any floor angle.

Last edited:

The grand finally.

Tow in. This seems to be a controversial subject due to our cars were originally equipped with bias ply tires which had much more movement and roll over when turning.

What I have been finding is that every one has an opinion without a lot of fact.

It ranges from set it to the original specs (1/8” toe in on my car) to neutral toe-in (0) to tow out.

What I have read is that with radial tires that if you have tow in (Per specs) it may want to chase highway cracks and ridges. If there is too much toe out, you will get wandering as well. Around neutral seems to be the most common answer. I am going to shoot for 0 to 1/16” of tow-in.

Tow in. This seems to be a controversial subject due to our cars were originally equipped with bias ply tires which had much more movement and roll over when turning.

What I have been finding is that every one has an opinion without a lot of fact.

It ranges from set it to the original specs (1/8” toe in on my car) to neutral toe-in (0) to tow out.

What I have read is that with radial tires that if you have tow in (Per specs) it may want to chase highway cracks and ridges. If there is too much toe out, you will get wandering as well. Around neutral seems to be the most common answer. I am going to shoot for 0 to 1/16” of tow-in.

First step is to center your steering wheel. I used a clamp wedging between the seat and floor.

Also when I pulled the car in the garage I made sure the car was straight with one of my expansion joints. This way I can make sure the wheels are straight when the steering wheel is centered.

I locked the steering wheel and then measured from each side of my alignment brackets back to the crack. I turned the left hand steering adjuster until the the wheel was parallel with the crack. (It was a couple of degrees off last summer.) I locked that adjuster in place and made sure my steering wheel was still straight. Then I moved over to the right side and finished the toe-in adjustment. I ended up with about 1/32” of tow-in. Close enough to zero and yet leaving me a little bit of tow-in like the original specs say.

We will see if it makes any difference and cuts down on chasing cracks compared to last year.

Hope the information helps.

Also when I pulled the car in the garage I made sure the car was straight with one of my expansion joints. This way I can make sure the wheels are straight when the steering wheel is centered.

I locked the steering wheel and then measured from each side of my alignment brackets back to the crack. I turned the left hand steering adjuster until the the wheel was parallel with the crack. (It was a couple of degrees off last summer.) I locked that adjuster in place and made sure my steering wheel was still straight. Then I moved over to the right side and finished the toe-in adjustment. I ended up with about 1/32” of tow-in. Close enough to zero and yet leaving me a little bit of tow-in like the original specs say.

We will see if it makes any difference and cuts down on chasing cracks compared to last year.

Hope the information helps.

live4theking

Old Man with a Hat

- Joined

- Nov 24, 2014

- Messages

- 12,902

- Reaction score

- 9,090

Thanks for the comprehensive thread. My father had a homemade bar that he used for setting toe in. Jack the front end up spin the wheels and mark with chalk. Set the car down and then check the difference front to back off the tire. He had a set of then tables for the front end to set on, but I don't recall seeing him use those. I like your plexiglass idea, a couple of thin pieces of sheetmetal with oil or grease would work too.

3175375

Old Man with a Hat

Nice write up and pictures.First step is to center your steering wheel. I used a clamp wedging between the seat and floor.

Also when I pulled the car in the garage I made sure the car was straight with one of my expansion joints. This way I can make sure the wheels are straight when the steering wheel is centered.

I locked the steering wheel and then measured from each side of my alignment brackets back to the crack. I turned the left hand steering adjuster until the the wheel was parallel with the crack. (It was a couple of degrees off last summer.) I locked that adjuster in place and made sure my steering wheel was still straight. Then I moved over to the right side and finished the toe-in adjustment. I ended up with about 1/32” of tow-in. Close enough to zero and yet leaving me a little bit of tow-in like the original specs say.

We will see if it makes any difference and cuts down on chasing cracks compared to last year.

Hope the information helps.

View attachment 362241 View attachment 362242 View attachment 362243

Isn’t toe supposed to be measured at the most forward and aft points of the tire? Long ago, I learned how to align all 4 wheels on a 66 Corvair and we measured at the mid-point, vertically of the tire.

we used a piece of angled steel with 1/8” welding rod mounted at each end to each up to the vertical midpoint of the tire....

Similar threads

- Replies

- 18

- Views

- 583

- Replies

- 7

- Views

- 1K

- Locked

- Replies

- 7

- Views

- 4K

- Replies

- 3

- Views

- 3K