hi,

it might be a good idea ( and it did not know what title to give to this thread ) to have a space to give or to gather files with 3D parts and reproduction files ( gaskets for exemple ) we have to make in order to get a new or to repair old parts.

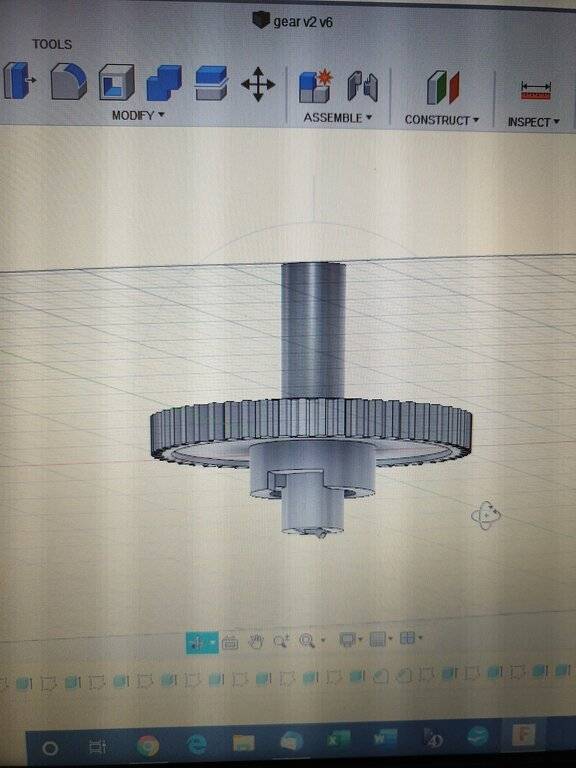

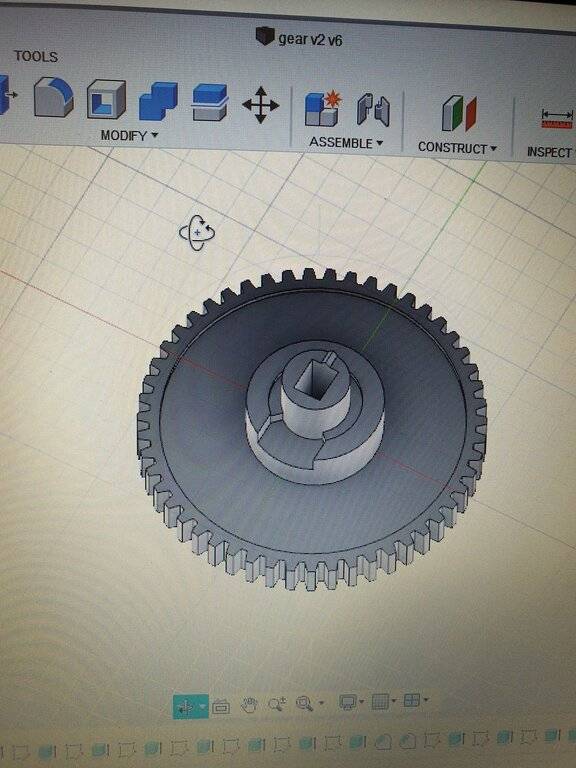

being confined at home i started to reproduce part I needed and i think it can be a good idea to share files. I started with the headlight motor gear : I did the 3D and a guy printed it and it is perfect. I tested it and it fit perfectly.

i choose not to reproduce the large theeth of the gear. i think that it may contribue to broke it. ( if the internal shut down system does not work the motor continue to roll but not the gear, i am thinking of an external system. )

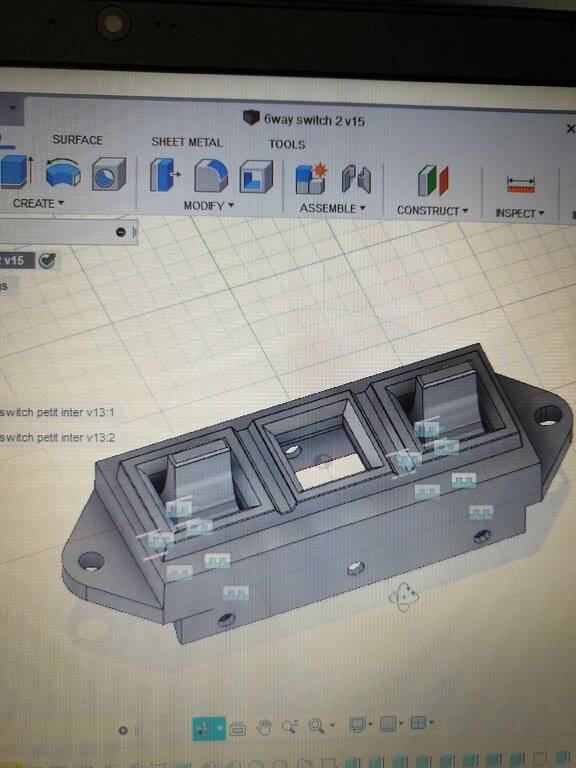

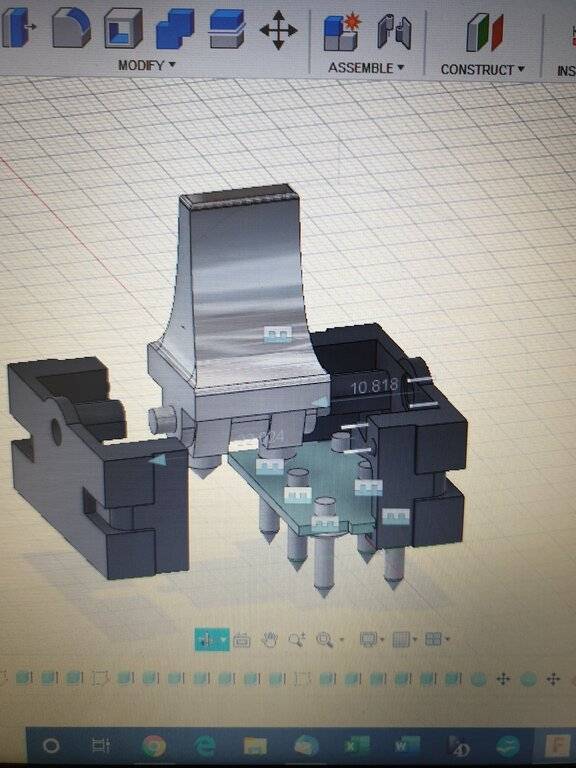

I am starting wotking on the seat switch

it might be a good idea ( and it did not know what title to give to this thread ) to have a space to give or to gather files with 3D parts and reproduction files ( gaskets for exemple ) we have to make in order to get a new or to repair old parts.

being confined at home i started to reproduce part I needed and i think it can be a good idea to share files. I started with the headlight motor gear : I did the 3D and a guy printed it and it is perfect. I tested it and it fit perfectly.

i choose not to reproduce the large theeth of the gear. i think that it may contribue to broke it. ( if the internal shut down system does not work the motor continue to roll but not the gear, i am thinking of an external system. )

I am starting wotking on the seat switch

Last edited: