Gerald Morris

Senior Member

The Poor Man’s Master Cylinder Upgrade

by: Gerald E. Morris

Brakes first concerned me just 3 days after purchasing Mathilda (our 2 door ‘66 Chrysler Newport). I had to replace drums, studs, shoes, springs all within the first month of owning Tilly. Front wheel cylinders and hoses followed a year later. By the second year’s end, I had GOOD brakes which stopped Mathilda’s hurtling 2.1 tons quickly, reliably and consistently, with but ONE fly polluting the DOT 3 fluid: the single pot master cylinder.

The lethal potential of this system manifest itself after I had replaced the front hoses. I neglected to tighten the left hose sufficiently (probably due to distraction from my get running amok while I worked), making a leak just dangerous enough to nearly drain the brake system the following evening as we returned home from worship. The brakes went suspiciously soft by the time I stopped for a Sunday supper of fried chicken. THANK GOD FOR CHURCH’S CHICKEN!

All but a couple tablespoons of the brake fluid had squirted out that loose hose fitting, as I saw from the telltale brake fluid under the fender. Carrying all sorts of tools, fluids and stuff in the trunk made it easy to refill the master cylinder. I tightened the hose and thanked the Lord and St. Joe for the timely warning, then drove us all home safe and sound. This convinced the wife that a few dollars on a master cylinder upgrade would be MOST WISELY invested. Despite having no further brake trouble, that business remained in mind until I got a good chance to effect the upgrade this summer.

I. By 1967, Mopar adopted dual pot master cylinders with strong encouragement from newly empowered Federal bureaucrats motivated in part by accident statistics on brake failure due to the inherent flaw of the venerable single pot design. For the majority of their vehicles, still equipped with drum brakes all around, the Bendix 2660809 succeeded resoundingly for 3 years.

The Bendix 2660809 Master Cylinder

I chose this because with a 1” bore, and the same piston stroke length as its predecessor, I could bolt it in without some booster complicating my brake system. Both Babushka and I alike loathe the FACT that brake boosters rely on a running engine to provide ready braking power. I’ve experienced several times in my misspent youth having the engine suddenly quit while thundering along the Interstate at some respectable multiple of the posted speed limit. I prefer to have brakes which work as well CONSISTENTLY without dependence on any extra power system.

This unit merits respect to this present day; so much so that its copied by those swinging capitalists in the “Peoples Middle Kingdom" or "Republic.” Had there been a shiny new U.S. made one readily available when I shopped for what I bought, I would have likely ponied up for it. As things are: I’m going to trust that the cast iron body of the unit I purchased has been competently poured. It seems so anyway. These sino-repops run between $65-75 on ePay. At least I didn’t have to pop for an adapter plate to bolt it in, as I would have for a Wilwood. It also works very nicely with the original pushrod.

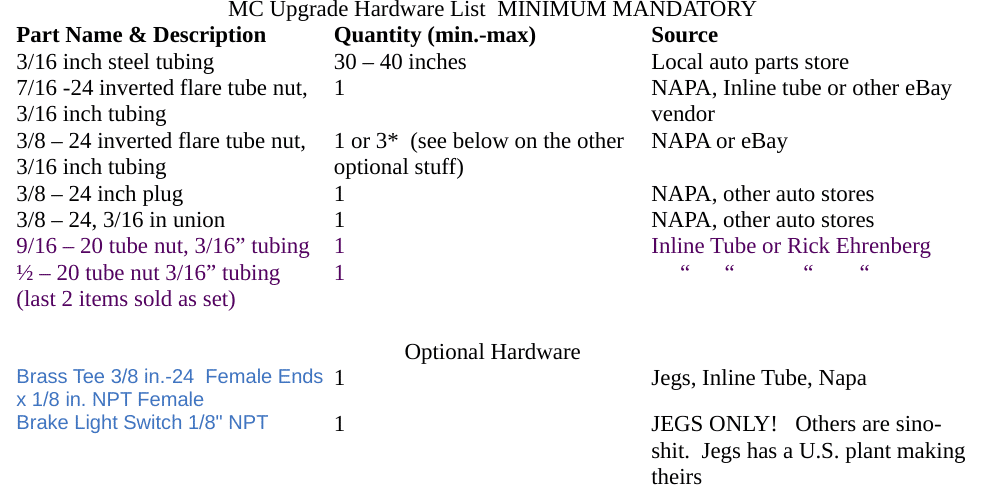

II. Aside from the MC, one needs a few other bits of hardware to upgrade.

(Note: this table had to be inserted as an image to preserve formatting --G.M

III. Disassemby

Remove the single pot MC as per your FSM. A 7/16” tube nut wrench should do to remove the ¼ inch

line from the old master cylinder to the 3 line junction block strapped to the front frame rail below.

Remove that line from the junction block now too. Take special care to use a proper 3/8” tube nut wrench when disconnecting the rear brake line from the junction block. I

Old Re-purposed Junction Block, plugged rear port.

STRONGLY advise one to remove the junction block from the frame rail by loosening the big sheet metal screw holding the strap down on the inner side of the rail prior to the attempt. This permits one to slip the tube nut wrench over the tube nut. Removing some of the wire wound around the tube as reinforcement and insulation near the nut also helps. (I HAD TO!)

Grasp the junction block with vice-grips, apply torque to the tube nut with your wrench, and pray that you don’t round off every one of the 6 hexagonal corners as you attempt breaking that nut loose. I JUST managed this, after much PB Blast, and several false starts which rounded 4 of the 6 corners off. After a prayer and BEATING the tube nut wrench back onto that tube nut, I FINALLY got it to turn. Decades of old, baked on hydrocarbons polymerized to hold that nut fast and I suspect my beating the wrench back on cracked this super-molecular bond enough to free the nut with further work. Oddly enough, neither front line nut gave half so much trouble.

After removing the rear line from the junction block, plug that rear hole with that 3/8-24 plug With a little blessing, you’ll never need to remove it. Make sure both front line nuts are snug in at this point also. If everything else came off and out, you can commence installing the new master cylinder.

IV. Installation.

Fill the new MC with the brake fluid of your choice and bench bleed it, then close the lid and plug the ports with your bleeding hoses or tubes. Hang it on the 4 studs meant for attaching to the firewall and tighten them to 100 inch-lbs. Leave off on the push-rod until all the lines have been securely installed and tightened.

Cut a 15 inch length of 3/16 line, slide on a 3/8-24 tube nut, double flare the end, then snug in the union. If all went satisfactorily thus far, screw the other female end of the union onto the tube nut on the rear line. Slide on the ½ -20 (blue) tube nut, double flare the other end of the 15 inch extension, bend a 90 degree turn about 2 inches from the end of the tube nut, then snug this into the front port on the MC, which will be labeled with an R for “Rear.”

Frontal view, Bendix (repop) MC w brake-light switch tee connected on fender.

Note how the rear brake line sweeps smoothly down to the union, visible just right of the gear selector at the bottom center of the picture above. Given that distance from the exhaust manifold has been optimized here, using the MC itself to shield this line, I deemed it unnecessary to put a cooling curve in this line. Given how the front line must connect to the junction block directly beneath the MC on the frame rail, it comes marginally closer to the manifold, so the cooling curve between the brake light switch tee and the cylinder serves to insure against vaporizing the brake fluid in this most important line.

IFF one cares to adopt a hydraulic brake light switch as I have, then one should next obtain a 7 inch length of 3/16 tubing, double flare one end, slide on a 7/16-24 tube nut and loosely start this into the top of the line junction block on the frame rail. Now slide down a 3/8-24 nut facing up, then flare the top end of the tube. Snug this into the hydraulic switch tee. If the switch hasn’t yet been screwed into the 1/8 inch NPT port at the middle of the tee, do so now.

Take about 15 inches of 3/16 tubing, flare one end, and slide your last 3/8-24 tube nut over that. Loosely screw this into the end of the tee, slide the 9/16-20 nut onto the other end, and flare that. Now, make a full 360 degree loop starting about 2 inches from the top of the green 9/16 nut. This bend will give a nice bit of flexibility to the tube as you then snug the 9/16 nut into the REAR port of the MC, which has a capital “F” for FRONT labeling it. Now snug down the last nut in the tee, but leave the 7/16-24 nut loose, or even back it off and put the end of the line into a clean jar for bleeding.

[ If foregoing the hydraulic switch, then you can connect directly from the top of the junction block to the front brake port on your MC. It takes a 15-20 inch piece of tubing to do this, depending on how much of a cooling loop, if any, you want to put in the tube. This way, you will have a VERY LOW material bill for your upgrade, though the hydraulic brake light switch isn’t too costly, and sure makes life easy. ]

NOW attach the push rod to the pedal after making sure it will slide smoothly into the master cylinder, pressing the pistons. If all went well, you now should slowly pump the brake pedal ONCE to bleed the new front brake line as far as the junction block. Once the line is air-free this far, you can snug the 7/16-24 nut down for good in the top of the old junction block. I found VERY FEW bubbles from either front brake cylinder after hooking everything up, I happily report!

The rear requires some serious bleeding. Go to the passenger side rear wheel, and place your bleeding reservoir and hose there. Open the port. Pump the brake a good 3 times. This will pump most of what little fluid the rear pot holds on the Bendix 2660809. Note how much dirty fluid and big bubbles turn up in your bleeding jar. Replace the lost fluid in the rear brake reservoir up front with new stuff, then pump again. Repeat this procedure until new, clean, bubble free fluid is ALL that fills the bleeding hose. Now, close the port, pump up pressure after filling the pot again, then, with a good weight on the pedal, go back, slowly open the port and watch for bubbles. If bubble-free at this point, close the port, bleed the other 3 wheel cylinders, then take your upgraded asphalt yacht for a cruise!

by: Gerald E. Morris

Brakes first concerned me just 3 days after purchasing Mathilda (our 2 door ‘66 Chrysler Newport). I had to replace drums, studs, shoes, springs all within the first month of owning Tilly. Front wheel cylinders and hoses followed a year later. By the second year’s end, I had GOOD brakes which stopped Mathilda’s hurtling 2.1 tons quickly, reliably and consistently, with but ONE fly polluting the DOT 3 fluid: the single pot master cylinder.

The lethal potential of this system manifest itself after I had replaced the front hoses. I neglected to tighten the left hose sufficiently (probably due to distraction from my get running amok while I worked), making a leak just dangerous enough to nearly drain the brake system the following evening as we returned home from worship. The brakes went suspiciously soft by the time I stopped for a Sunday supper of fried chicken. THANK GOD FOR CHURCH’S CHICKEN!

All but a couple tablespoons of the brake fluid had squirted out that loose hose fitting, as I saw from the telltale brake fluid under the fender. Carrying all sorts of tools, fluids and stuff in the trunk made it easy to refill the master cylinder. I tightened the hose and thanked the Lord and St. Joe for the timely warning, then drove us all home safe and sound. This convinced the wife that a few dollars on a master cylinder upgrade would be MOST WISELY invested. Despite having no further brake trouble, that business remained in mind until I got a good chance to effect the upgrade this summer.

I. By 1967, Mopar adopted dual pot master cylinders with strong encouragement from newly empowered Federal bureaucrats motivated in part by accident statistics on brake failure due to the inherent flaw of the venerable single pot design. For the majority of their vehicles, still equipped with drum brakes all around, the Bendix 2660809 succeeded resoundingly for 3 years.

The Bendix 2660809 Master Cylinder

This unit merits respect to this present day; so much so that its copied by those swinging capitalists in the “Peoples Middle Kingdom" or "Republic.” Had there been a shiny new U.S. made one readily available when I shopped for what I bought, I would have likely ponied up for it. As things are: I’m going to trust that the cast iron body of the unit I purchased has been competently poured. It seems so anyway. These sino-repops run between $65-75 on ePay. At least I didn’t have to pop for an adapter plate to bolt it in, as I would have for a Wilwood. It also works very nicely with the original pushrod.

II. Aside from the MC, one needs a few other bits of hardware to upgrade.

(Note: this table had to be inserted as an image to preserve formatting --G.M

III. Disassemby

Remove the single pot MC as per your FSM. A 7/16” tube nut wrench should do to remove the ¼ inch

line from the old master cylinder to the 3 line junction block strapped to the front frame rail below.

Remove that line from the junction block now too. Take special care to use a proper 3/8” tube nut wrench when disconnecting the rear brake line from the junction block. I

Old Re-purposed Junction Block, plugged rear port.

Grasp the junction block with vice-grips, apply torque to the tube nut with your wrench, and pray that you don’t round off every one of the 6 hexagonal corners as you attempt breaking that nut loose. I JUST managed this, after much PB Blast, and several false starts which rounded 4 of the 6 corners off. After a prayer and BEATING the tube nut wrench back onto that tube nut, I FINALLY got it to turn. Decades of old, baked on hydrocarbons polymerized to hold that nut fast and I suspect my beating the wrench back on cracked this super-molecular bond enough to free the nut with further work. Oddly enough, neither front line nut gave half so much trouble.

After removing the rear line from the junction block, plug that rear hole with that 3/8-24 plug With a little blessing, you’ll never need to remove it. Make sure both front line nuts are snug in at this point also. If everything else came off and out, you can commence installing the new master cylinder.

IV. Installation.

Fill the new MC with the brake fluid of your choice and bench bleed it, then close the lid and plug the ports with your bleeding hoses or tubes. Hang it on the 4 studs meant for attaching to the firewall and tighten them to 100 inch-lbs. Leave off on the push-rod until all the lines have been securely installed and tightened.

Cut a 15 inch length of 3/16 line, slide on a 3/8-24 tube nut, double flare the end, then snug in the union. If all went satisfactorily thus far, screw the other female end of the union onto the tube nut on the rear line. Slide on the ½ -20 (blue) tube nut, double flare the other end of the 15 inch extension, bend a 90 degree turn about 2 inches from the end of the tube nut, then snug this into the front port on the MC, which will be labeled with an R for “Rear.”

Frontal view, Bendix (repop) MC w brake-light switch tee connected on fender.

IFF one cares to adopt a hydraulic brake light switch as I have, then one should next obtain a 7 inch length of 3/16 tubing, double flare one end, slide on a 7/16-24 tube nut and loosely start this into the top of the line junction block on the frame rail. Now slide down a 3/8-24 nut facing up, then flare the top end of the tube. Snug this into the hydraulic switch tee. If the switch hasn’t yet been screwed into the 1/8 inch NPT port at the middle of the tee, do so now.

Take about 15 inches of 3/16 tubing, flare one end, and slide your last 3/8-24 tube nut over that. Loosely screw this into the end of the tee, slide the 9/16-20 nut onto the other end, and flare that. Now, make a full 360 degree loop starting about 2 inches from the top of the green 9/16 nut. This bend will give a nice bit of flexibility to the tube as you then snug the 9/16 nut into the REAR port of the MC, which has a capital “F” for FRONT labeling it. Now snug down the last nut in the tee, but leave the 7/16-24 nut loose, or even back it off and put the end of the line into a clean jar for bleeding.

[ If foregoing the hydraulic switch, then you can connect directly from the top of the junction block to the front brake port on your MC. It takes a 15-20 inch piece of tubing to do this, depending on how much of a cooling loop, if any, you want to put in the tube. This way, you will have a VERY LOW material bill for your upgrade, though the hydraulic brake light switch isn’t too costly, and sure makes life easy. ]

NOW attach the push rod to the pedal after making sure it will slide smoothly into the master cylinder, pressing the pistons. If all went well, you now should slowly pump the brake pedal ONCE to bleed the new front brake line as far as the junction block. Once the line is air-free this far, you can snug the 7/16-24 nut down for good in the top of the old junction block. I found VERY FEW bubbles from either front brake cylinder after hooking everything up, I happily report!

The rear requires some serious bleeding. Go to the passenger side rear wheel, and place your bleeding reservoir and hose there. Open the port. Pump the brake a good 3 times. This will pump most of what little fluid the rear pot holds on the Bendix 2660809. Note how much dirty fluid and big bubbles turn up in your bleeding jar. Replace the lost fluid in the rear brake reservoir up front with new stuff, then pump again. Repeat this procedure until new, clean, bubble free fluid is ALL that fills the bleeding hose. Now, close the port, pump up pressure after filling the pot again, then, with a good weight on the pedal, go back, slowly open the port and watch for bubbles. If bubble-free at this point, close the port, bleed the other 3 wheel cylinders, then take your upgraded asphalt yacht for a cruise!

Last edited: