1970FuryConv

Old Man with a Hat

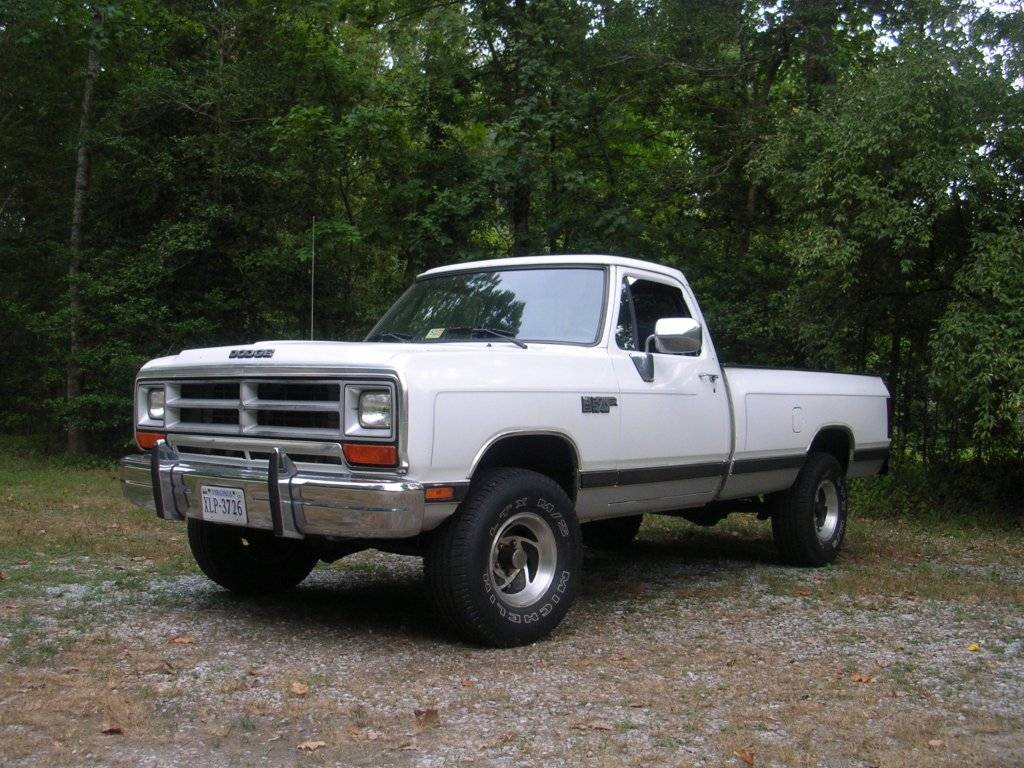

I have a 1990 W150 Power Ram 5.9/46RH. It has TBI with a return fuel line. It has SBEC as its computer. It has a Hall effect distributor with a 5 V return wire to the computer that allows the computer to calculate RPM and helps the computer to then calculate the amount of fuel to send through the 2 fuel injectors at the throttle body.

The truck spontaneously and unpredictably cuts off while driving - engine's hot. There is no coughing or sputtering. It just immediately cuts off. Then after waiting a few minutes, it starts up again and drives home like normal. I have a friend with a 96 1500 that is doing the same thing. I’ve been over the coil, the wiring, the distributor. I replaced the Hall effect sensor three times. I’ve replaced the SBEC with a rebuilt Delco unit. I replaced the fuel pump. Replaced the fuel filter twice. Checked all kinds of wiring. I’m coming to wits end on this. Has anyone run into this problem? How did you fix it? Thanks for any help, Ben

The truck spontaneously and unpredictably cuts off while driving - engine's hot. There is no coughing or sputtering. It just immediately cuts off. Then after waiting a few minutes, it starts up again and drives home like normal. I have a friend with a 96 1500 that is doing the same thing. I’ve been over the coil, the wiring, the distributor. I replaced the Hall effect sensor three times. I’ve replaced the SBEC with a rebuilt Delco unit. I replaced the fuel pump. Replaced the fuel filter twice. Checked all kinds of wiring. I’m coming to wits end on this. Has anyone run into this problem? How did you fix it? Thanks for any help, Ben

It's the little things that kill. I put the engine in this truck. I set up all the pulleys and electrical. I put the transmission in the truck. I put the transfer case and driveshaft in the truck. I put both axles on the truck. I rebuilt the steering & steering portion of the front axle. I did the brakes. And now after 13 years it has developed this problem.

It's the little things that kill. I put the engine in this truck. I set up all the pulleys and electrical. I put the transmission in the truck. I put the transfer case and driveshaft in the truck. I put both axles on the truck. I rebuilt the steering & steering portion of the front axle. I did the brakes. And now after 13 years it has developed this problem.