Today’s bit of progress…. Only had 2 hours to give it.

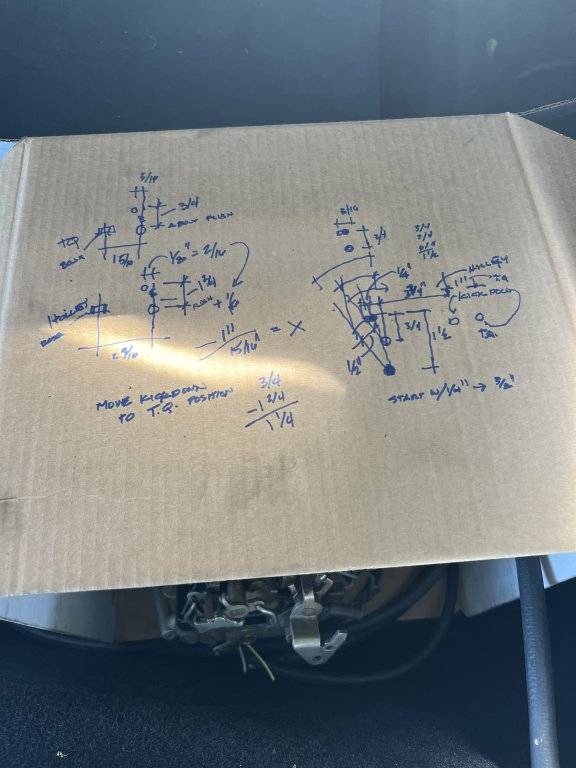

Some measurements to see how much I needed to extend the slot in the kickdown bar. Holley linkage sits an inch further back than the Thermoquad and about 3/4 inch higher. Distance between center lines of throttles shafts to the linkage points are about the same (with my fabricated adapter). But being higher on the Holley, I’m running into the bottom of the air cleaner with the Cruise control linkage by about 3/8 of an inch. Will need to relocate it outboard and down. I have a longer link to use to make up the difference.

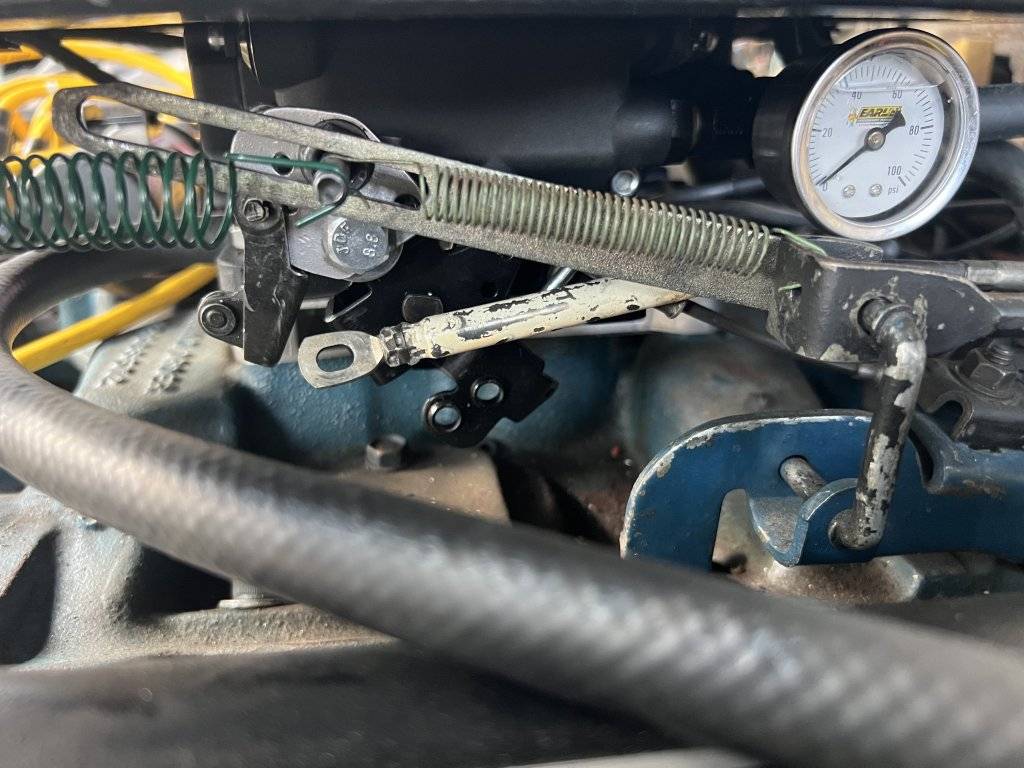

Here it is installed…. Went with 1/2 inch figuring I can creat an adjustment later to make downshifts where I want it. It just touches at about 20% throttle per the on board TPS.

Cleaned up the wires to the ballast.

Still a few wires to go. The original coil positive, the purple temp sensor wire, a/c compressor wire and a blue wire with white tracer I haven’t been able to figure out. Anyone out there know?

These I want to wrap and put away from the coil and temp sensor to the Holley (which are already in their own holly provided cover).

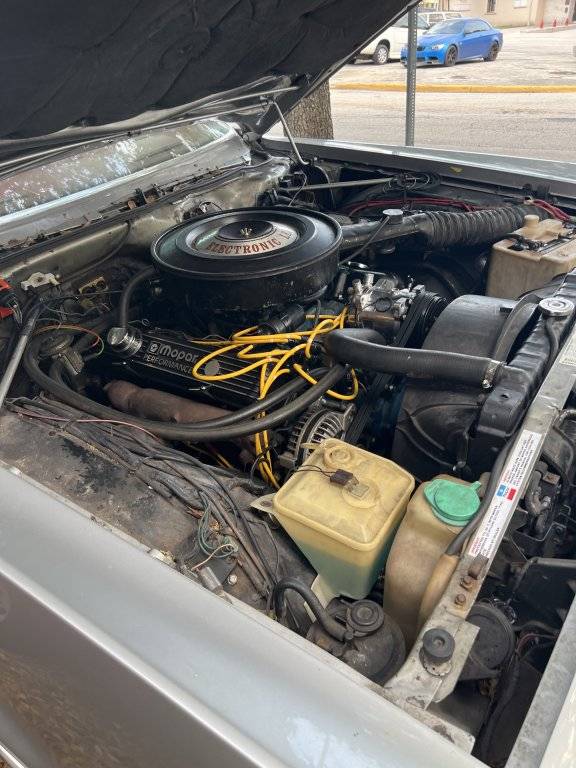

Overall view…. outside this time. She’s a roller now and they need room in the shop for more “profitable work”.

Anyone out there have a 440 air cleaner without the hole I can buy?

Some measurements to see how much I needed to extend the slot in the kickdown bar. Holley linkage sits an inch further back than the Thermoquad and about 3/4 inch higher. Distance between center lines of throttles shafts to the linkage points are about the same (with my fabricated adapter). But being higher on the Holley, I’m running into the bottom of the air cleaner with the Cruise control linkage by about 3/8 of an inch. Will need to relocate it outboard and down. I have a longer link to use to make up the difference.

Here it is installed…. Went with 1/2 inch figuring I can creat an adjustment later to make downshifts where I want it. It just touches at about 20% throttle per the on board TPS.

Cleaned up the wires to the ballast.

Still a few wires to go. The original coil positive, the purple temp sensor wire, a/c compressor wire and a blue wire with white tracer I haven’t been able to figure out. Anyone out there know?

These I want to wrap and put away from the coil and temp sensor to the Holley (which are already in their own holly provided cover).

Overall view…. outside this time. She’s a roller now and they need room in the shop for more “profitable work”.

Anyone out there have a 440 air cleaner without the hole I can buy?

Last edited: