69 Chrysler 300.

Who is/are the Guru's for dashboard repair and correct type & size fasteners? I have some broken tabs and missing screws/clip nuts.

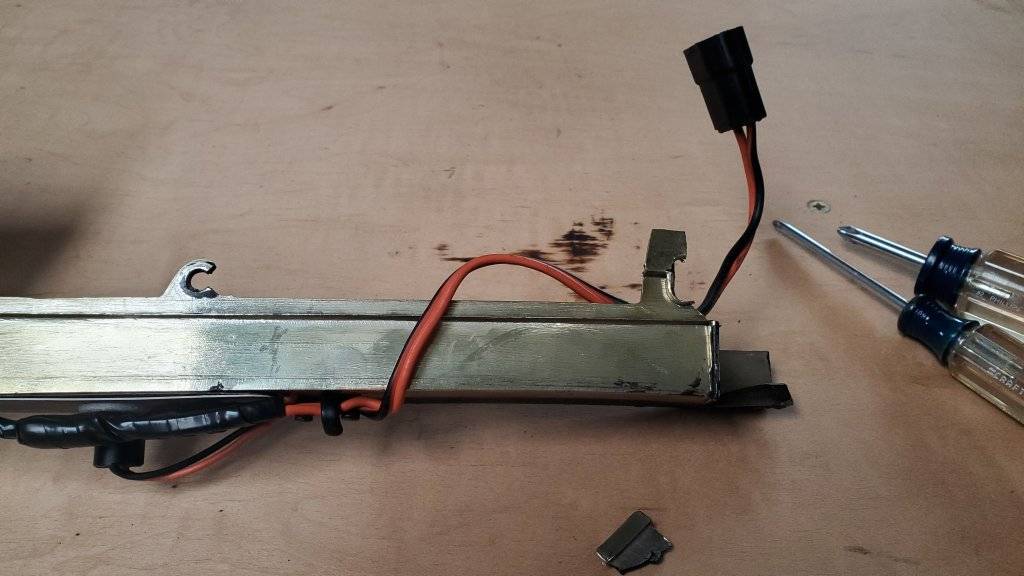

In the last two photos, the lower part of the metal Dash has several square & rectangular cut outs. Am I missing a Cover or Part?

Thx

Who is/are the Guru's for dashboard repair and correct type & size fasteners? I have some broken tabs and missing screws/clip nuts.

In the last two photos, the lower part of the metal Dash has several square & rectangular cut outs. Am I missing a Cover or Part?

Thx