MoJo

New Member

Before posting, I always search the forums for suggestions to help resolve any issues on my 1966 300. I followed all the posted suggestion and still cannot figure out why the fuel gauge is not working. In any event, I trying to troubleshoot why my fuel gauge reads empty all the time. Below are the steps and results I've done so far in trying to resolve the problem:

1. Checked an verified all fuses are good

2. Put temp ground jumper on fuel sending unit body and tested ground with test light all the way back to the battery to verify good ground - Result, no change in the fuel gauge

3. Put test light on sending unit wire at the tank and got a pulsating light on the tester

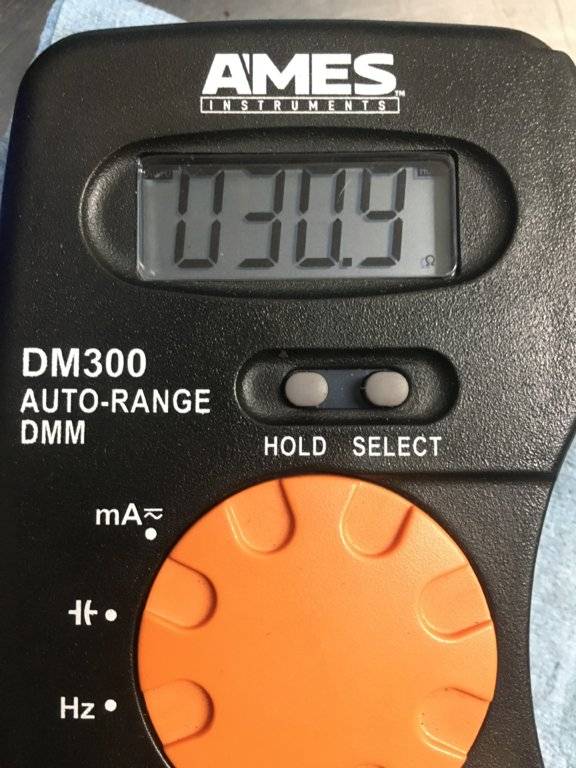

4. Put ohm meter across the fuel sending unit connector stud and unit ground and read 31 ohms

5. Grounded out the fuel sending wire and gauge swings over to full when i turn on the key.

So, I've got a good ground at the sending unit, pulsating voltage on the wire at the tank which indicates the voltage limiter is working, 31 ohms through the sending unit and I verified the gauge works when grounding the wire at the tank. It should be reading 1/3 to 1/2 of a tank, but only shows empty. Of course, this sending unit was new when I installed it last year and hasn't worked from day one. Any thoughts?

1. Checked an verified all fuses are good

2. Put temp ground jumper on fuel sending unit body and tested ground with test light all the way back to the battery to verify good ground - Result, no change in the fuel gauge

3. Put test light on sending unit wire at the tank and got a pulsating light on the tester

4. Put ohm meter across the fuel sending unit connector stud and unit ground and read 31 ohms

5. Grounded out the fuel sending wire and gauge swings over to full when i turn on the key.

So, I've got a good ground at the sending unit, pulsating voltage on the wire at the tank which indicates the voltage limiter is working, 31 ohms through the sending unit and I verified the gauge works when grounding the wire at the tank. It should be reading 1/3 to 1/2 of a tank, but only shows empty. Of course, this sending unit was new when I installed it last year and hasn't worked from day one. Any thoughts?