WissaMan

Well-Known Member

- Joined

- Sep 12, 2018

- Messages

- 597

- Reaction score

- 607

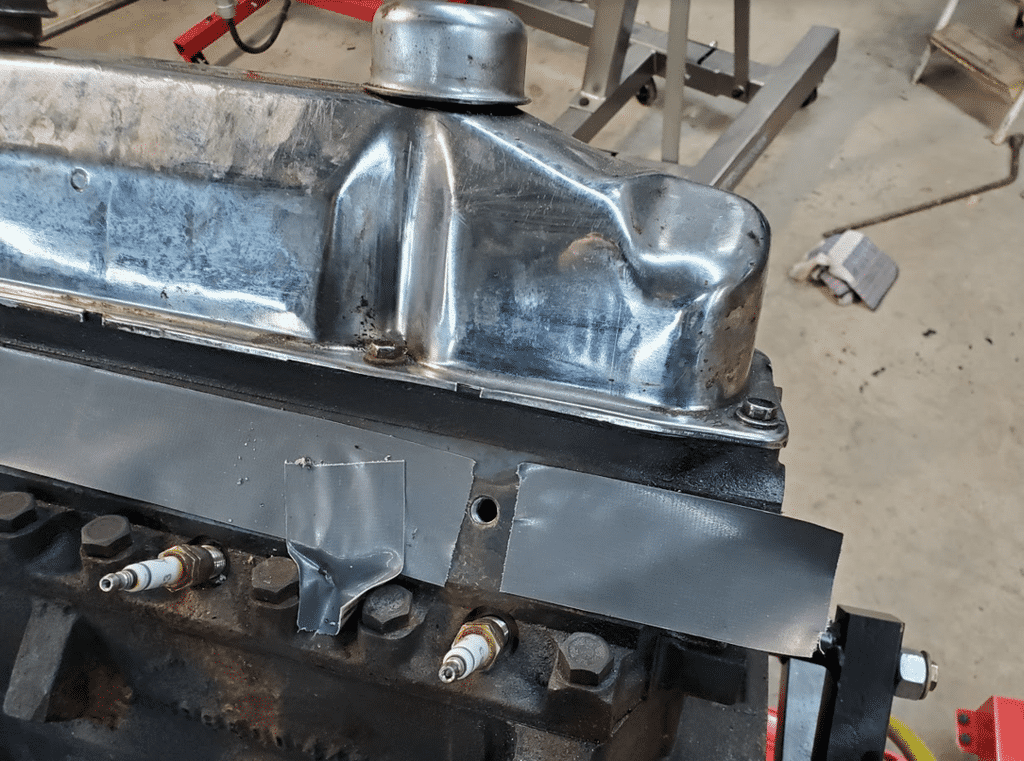

So this 440 I'm working on had an exhaust manifold stud broken off previously. It's on the driver side, to the right of the #7 exhaust port. It actually did not show any signs of having been leaking around the gasket in that area, but I thought it'd be the proper thing to do to get that out of there before putting the HP manifolds on.

Frustratingly, the bolt extractor broke off when trying to back the stud out so I had to drill that out too. Fortunately, there is a tool that can do it called the Rescue Bit, you can find it here. It's pricey but really does work.

so I had to drill that out too. Fortunately, there is a tool that can do it called the Rescue Bit, you can find it here. It's pricey but really does work.

Anywho, as I was grinding out the stud/extractor combo with the Rescue Bit, it went all the way through and there was nothing beyond it. When I took the tape off the exhaust ports, I could see some metal grindings sitting on top of the exhaust valve, which unfortunately was open so I can only assume some metal grindings got inside the combustion chamber.

So how screwed am I? Do I need to pull the head and thoroughly clean it and the cylinder? Or should I trying hitting it with a good dose of compressed air and hope for the best? Or maybe rotate the engine so the exhaust port is face down and spray WD-40 into the cylinder to flush it out?

Mind you, this is not a freshly rebuilt motor (as you can plainly see lol). I just want to drop a running motor into my 68 Newport to get it moving under it's own power so I can access the rest of the car's drive train, suspension, etc. So I'm not concerned with perfection. But at the same time, I don't want to totally f-up the cylinder wall either as I'm guessing that could potentially make it the block non-rebuildable.

Thoughts / opinions?

And go ahead and feel free to call me a doofus if I should've known better

Frustratingly, the bolt extractor broke off when trying to back the stud out

so I had to drill that out too. Fortunately, there is a tool that can do it called the Rescue Bit, you can find it here. It's pricey but really does work.

so I had to drill that out too. Fortunately, there is a tool that can do it called the Rescue Bit, you can find it here. It's pricey but really does work.Anywho, as I was grinding out the stud/extractor combo with the Rescue Bit, it went all the way through and there was nothing beyond it. When I took the tape off the exhaust ports, I could see some metal grindings sitting on top of the exhaust valve, which unfortunately was open so I can only assume some metal grindings got inside the combustion chamber.

So how screwed am I? Do I need to pull the head and thoroughly clean it and the cylinder? Or should I trying hitting it with a good dose of compressed air and hope for the best? Or maybe rotate the engine so the exhaust port is face down and spray WD-40 into the cylinder to flush it out?

Mind you, this is not a freshly rebuilt motor (as you can plainly see lol). I just want to drop a running motor into my 68 Newport to get it moving under it's own power so I can access the rest of the car's drive train, suspension, etc. So I'm not concerned with perfection. But at the same time, I don't want to totally f-up the cylinder wall either as I'm guessing that could potentially make it the block non-rebuildable.

Thoughts / opinions?

And go ahead and feel free to call me a doofus if I should've known better