challenger

Active Member

I don't know why this thing is being such a problem but the steering column, which I removed to R&R the input seal on the PS box, isn't lining up as described in the FSM.

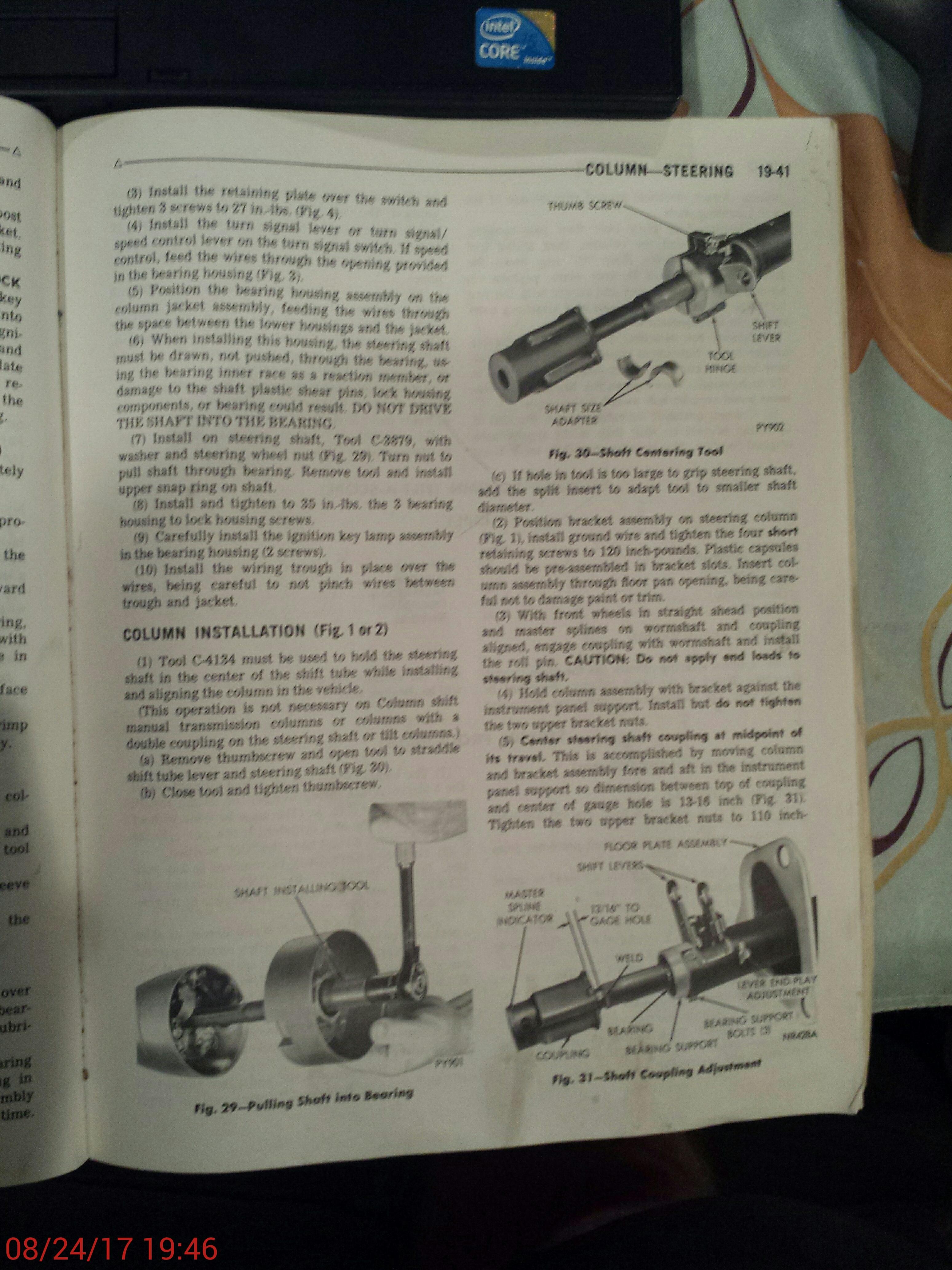

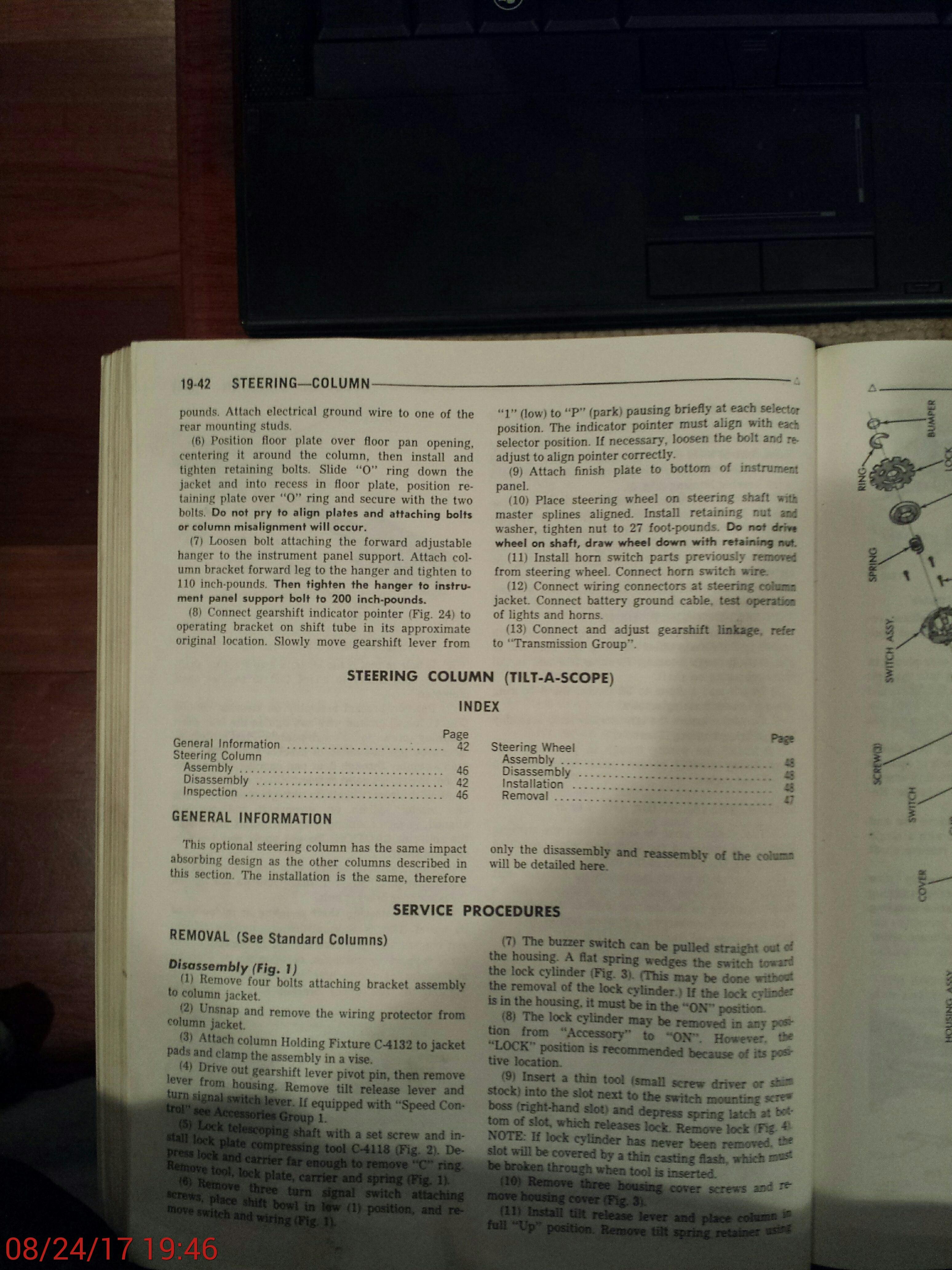

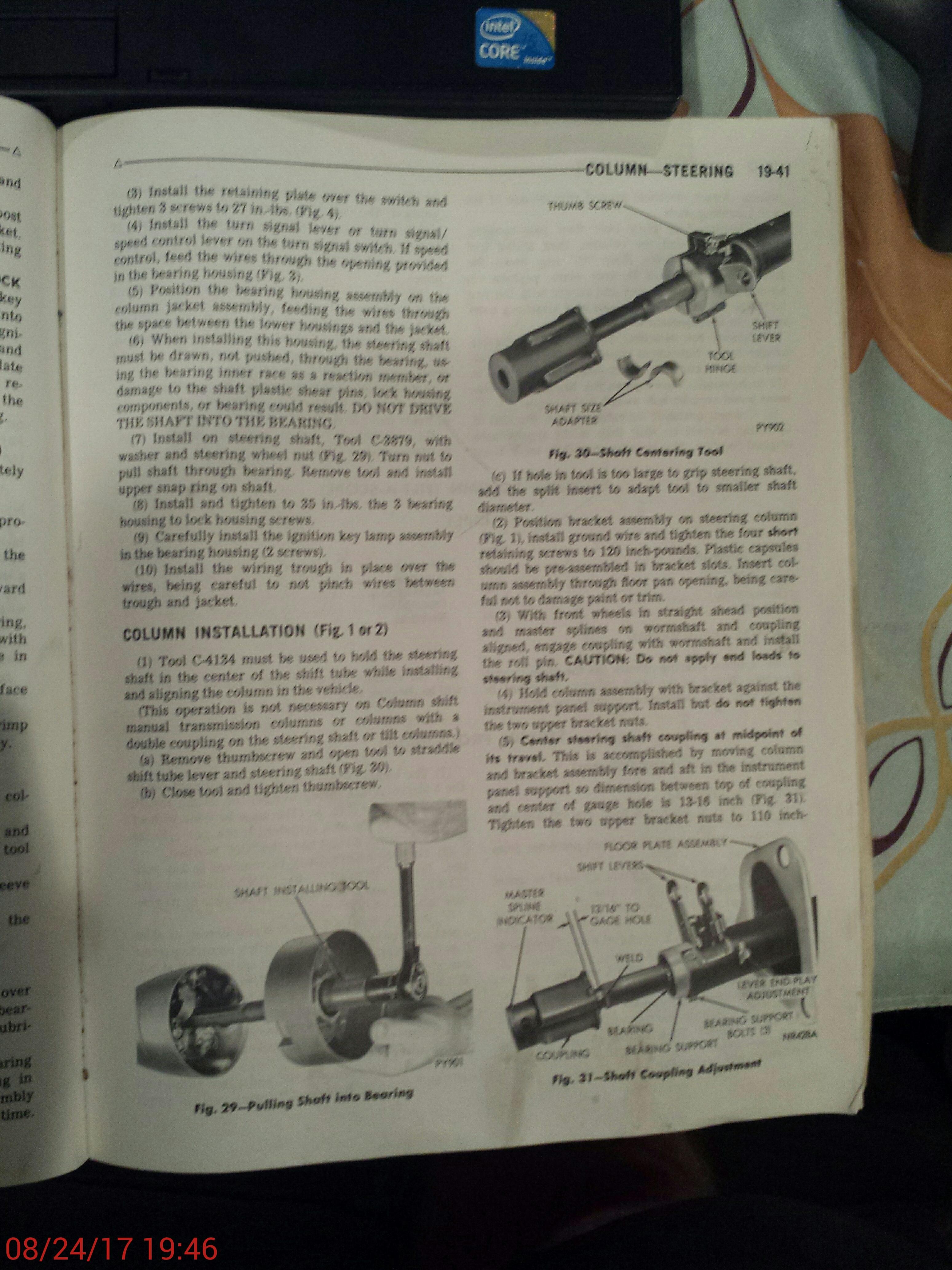

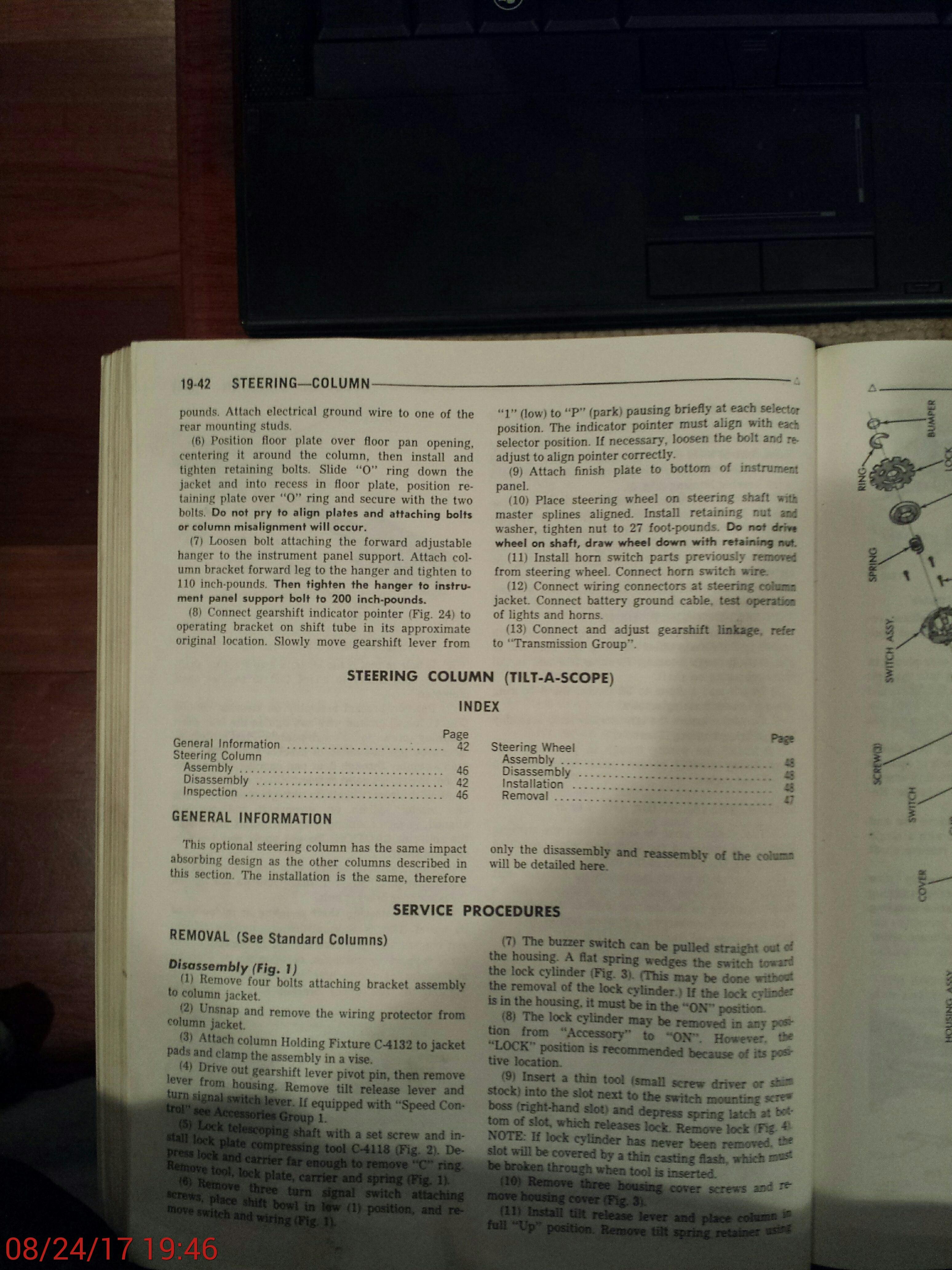

The current problem I have is with the steering shaft not being in the center of the shift tube. For some reason the FSM for this car and I have a terrible communication problem. I've worked on several Mopars and had a FSM for all of them but this one always finds a way to confuse the **** out of me. Here are the pages, from my FSM, for the installation of the column:

I do not have a shaft centering tool so I figured I could snug up the 3 floor bolts and center the shaft by using the pressure from the bolts to keep the shift tube somewhat centered. This has not worked so far. The bolts either get tightened too much or too little so the tube either won't stay somewhat centered ot I can't move it. In addition to this the manual never states when to remove the centering tool from the tube. As mentioned, I am not going to use the tool BUT I'd like to know if its use is finished after everything is tightened up are somewhere else? The main reason I ask this is because I really can't figure out WTF the reason is for having the "O" ring retainer. Is it to secure the tube to the floor plate?

Lastly what impact does the rear hanger bracket and bolt have on the whole alignment of the column/shaft/shift tube. There doesn't seem to be much play in the bracket yet it is one of the last items to be tightened down.

BTW - is there a simply tool that others have used to keep the shaft centered in the shift tube?

The current problem I have is with the steering shaft not being in the center of the shift tube. For some reason the FSM for this car and I have a terrible communication problem. I've worked on several Mopars and had a FSM for all of them but this one always finds a way to confuse the **** out of me. Here are the pages, from my FSM, for the installation of the column:

I do not have a shaft centering tool so I figured I could snug up the 3 floor bolts and center the shaft by using the pressure from the bolts to keep the shift tube somewhat centered. This has not worked so far. The bolts either get tightened too much or too little so the tube either won't stay somewhat centered ot I can't move it. In addition to this the manual never states when to remove the centering tool from the tube. As mentioned, I am not going to use the tool BUT I'd like to know if its use is finished after everything is tightened up are somewhere else? The main reason I ask this is because I really can't figure out WTF the reason is for having the "O" ring retainer. Is it to secure the tube to the floor plate?

Lastly what impact does the rear hanger bracket and bolt have on the whole alignment of the column/shaft/shift tube. There doesn't seem to be much play in the bracket yet it is one of the last items to be tightened down.

BTW - is there a simply tool that others have used to keep the shaft centered in the shift tube?