Rest it back on the stands incrementally and see...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New Member, New Polara

- Thread starter Stev

- Start date

Stev

Active Member

Rest it back on the stands incrementally and see...

I did it both ways with little progress. My hand was constantly on the latch looking for it to soften up. Nothing. And I was very afraid about opening the gate and losing the sill, I only want to find the correct sweet spot to leave it exactly there. As far as the car is concerned, the only important geometry is the front leaf spring pads which the donor locates innately. Everything else is just visual, if it looks right, it is right.

I got bodyshop buddy coming over sometime this week. He's got all the proper collision repair jacks, pullers, pushers, and the knowhow to use them. we'll sort it out and brace the car properly. Until then I'll just get other work done like getting the RR wheelhouse donor ready to go in, maybe even get the wheelhouse out while I wait.

By the by, I really need the upper RR door monaco trim and one of the reverse light bezels on the bumper. Wildcat didn't have any. If anyone here does, let me know. Nothing on Ebay or here that i can see.

Last edited:

Stev

Active Member

Still waiting on bodyshop friend. He's hard to get around when there's a pile of money on the table, let alone favours.

While i'm here, what's the proper way to extract the rear leaf spring hanger from the spring eye bushing and hanger bracket? They're in there real good on both sets of springs, and the studs appear to be integral to the hanger plate, or at least press fit, so i'm averse to just smashing them out like a caveman or using a puller which risks bending the stud.

The shop manual is very unhelpful and only suggests "removing" them.

While i'm here, what's the proper way to extract the rear leaf spring hanger from the spring eye bushing and hanger bracket? They're in there real good on both sets of springs, and the studs appear to be integral to the hanger plate, or at least press fit, so i'm averse to just smashing them out like a caveman or using a puller which risks bending the stud.

The shop manual is very unhelpful and only suggests "removing" them.

I would ask the spring hanger questions of a spring shop.

Stev

Active Member

No-one like that around here. I live in a remote area, so we have a body shop, interior shop and a few mechanics. But nothing as specialized as a spring shop or transmission shop.

The ones that were on the car are pretty crusty, and the donor's are ok. If no one has any better ideas, i'm just going to put the nut on the bad ones and see if I can beat them out safely or not. Worst case i'll just have to paint the donor's main spring in place.

The ones that were on the car are pretty crusty, and the donor's are ok. If no one has any better ideas, i'm just going to put the nut on the bad ones and see if I can beat them out safely or not. Worst case i'll just have to paint the donor's main spring in place.

Last edited:

3175375

Old Man with a Hat

You might get some ideas by searching on YouTube. I looked and couldn’t find a silver bullet, but you might find a video that helps.No-one like that around here. I live in a remote area, so we have a body shop, interior shop and a few mechanics. But nothing as specialized as a spring shop or transmission shop.

The ones that were on the car are pretty crusty, and the donor's are ok. If no one has any better ideas, i'm just going to put the nut on the bad ones and see if I can beat them out safely or not. Worst case i'll just have to paint the donor's main spring in place.

My three 67 Polaras

Member

On mine I replaced the leaf springs and hardware, so I did not have to worry about that (mine may have fallen out of the bushing anyway) but on other makes if tapping them out with penetrant-soaking does not work, I sometimes chew through the rubber between the spring eye and the bolt with an appropriately sized hole saw; devoid of the mandrel centering drill. That is only going to get you half the distance to the goal; depth wise. Then try beating on them some more. A brass hammer or soft blow hammer is preferred. These pieces are often unusable due to either rust or the stud snapping off when the nut is untorqued. I got my hardware (including the shackle bolts), from Esso's.While i'm here, what's the proper way to extract the rear leaf spring hanger from the spring eye bushing and hanger bracket? They're in there real good on both sets of springs, and the studs appear to be integral to the hanger plate, or at least press fit, so i'm averse to just smashing them out like a caveman or using a puller which risks bending the stud.

Leaf Spring Shackles, Bushings, Ubolts | ESPO Springs n Things

Leaf spring shackles, ubolts, eye bolts, bushings and axle pads from ESPO Springs 'n Things. Both rubber and polyurethane bushings available.

mopar preferred

Active Member

Per the owners manual, the tail gate unlocks by turning the key to lower the window, locks by raising it.View attachment 636814

May have screwed myself. I jacked it up by the tailgate sill to the point where the car is off the jackstands and the tailgate latch still won't budge

The tailgate latch doesn't lock does it? I remember the key only running the motor switch but the gate can be opened at any time. I was futzing with the keys but they don't seem to work, though there is a lot of slop in the key cylinder.

Makes sense, as you would not want to lower the gate with the window up.

Since you had to help the window down, maybe the locking mechanism has not released. There is a safety mechanism involved to prevent the gate from opening with the glass up.

That said, jacking under the gate could have jammed it in place.

Perhaps you could remove the inner trim panel to get a visual.

Stev

Active Member

On mine I replaced the leaf springs and hardware, so I did not have to worry about that (mine may have fallen out of the bushing anyway) but on other makes if tapping them out with penetrant-soaking does not work, I sometimes chew through the rubber between the spring eye and the bolt with an appropriately sized hole saw; devoid of the mandrel centering drill. That is only going to get you half the distance to the goal; depth wise. Then try beating on them some more. A brass hammer or soft blow hammer is preferred. These pieces are often unusable due to either rust or the stud snapping off when the nut is untorqued. I got my hardware (including the shackle bolts), from Esso's.

Leaf Spring Shackles, Bushings, Ubolts | ESPO Springs n Things

Leaf spring shackles, ubolts, eye bolts, bushings and axle pads from ESPO Springs 'n Things. Both rubber and polyurethane bushings available.www.springsnthings.com

I'll give that a try, thanks. The trouble is the bolt seems seized in the metal spacer inside the eye, not the bushing itself. If i can't get the junk ones off safely I'll just use the donor's as they sit, they seem very good.

I have a ghetto puller made of pipe and washers I use to pull bronze bushings, which is basically what the shop manual reccomends, just trying to preserve the shackle.

Per the owners manual, the tail gate unlocks by turning the key to lower the window, locks by raising it.

Makes sense, as you would not want to lower the gate with the window up.

Since you had to help the window down, maybe the locking mechanism has not released. There is a safety mechanism involved to prevent the gate from opening with the glass up.

That said, jacking under the gate could have jammed it in place.

Perhaps you could remove the inner trim panel to get a visual.

I was in there, I didn't think there was a locking device, the handle seemed to work a bell crank that pulls on tabs to release the tailgate. I didn't see any interrupting device, and it opened quite happily with the glass slightly opened before. If there is one, it'd be on the other side of the regulator, which of course requires removing the glass to remove or service.

The glass is presently fully bottomed out. I can futz with the position a bunch I suppose

The only "interrupting device" is the "open gate glass up preventer" - if the gate is open, the glass can only be retracted into the gate.

This is done by a circuit spring on the driver side of the tgate opening. Opens the up circuit if the latch doesn't press it. One can override it with a screwdiver pressing it closed while someone else pushes the switch. DO NOT over-extend the glass. DO NOT close the gate with glass up, as it will smash against the body.

There is no physical latch preventer. I'm still leaning towards a physical misalignment binding the strikers.

If you take the inside cover off you should be able to retract them with some sort of tool if someone helps wiggle the handle into the open position.

This is done by a circuit spring on the driver side of the tgate opening. Opens the up circuit if the latch doesn't press it. One can override it with a screwdiver pressing it closed while someone else pushes the switch. DO NOT over-extend the glass. DO NOT close the gate with glass up, as it will smash against the body.

There is no physical latch preventer. I'm still leaning towards a physical misalignment binding the strikers.

If you take the inside cover off you should be able to retract them with some sort of tool if someone helps wiggle the handle into the open position.

Stev

Active Member

The only "interrupting device" is the "open gate glass up preventer" - if the gate is open, the glass can only be retracted into the gate.

This is done by a circuit spring on the driver side of the tgate opening. Opens the up circuit if the latch doesn't press it. One can override it with a screwdiver pressing it closed while someone else pushes the switch. DO NOT over-extend the glass. DO NOT close the gate with glass up, as it will smash against the body.

There is no physical latch preventer. I'm still leaning towards a physical misalignment binding the strikers.

If you take the inside cover off you should be able to retract them with some sort of tool if someone helps wiggle the handle into the open position.

then that never worked because i can raise the glass no problem with the gate open, and it has always been that way. The glass is fully retracted after I freed up the mechanism, moving it is not an issue.

I agree about the latch binding, i think the bottom of the sill moved forward slightly and the gate is the only thing keeping it from going further. I will not mess with it until body shop friend gets a look at it.

Worst case scenario i will just leave it in place until the floor is in and weight is on the ground again. The gate was already misaligned anyway, it is so far rearward the little folding panel that fills the gap falls off the gate and into the gap when opened, and the whole gate is very noticeably offset to the left side. It needs realignment anyway, not desirable but not the end of the world.

Bodyshop friend said he'll be here tomorrow or tuesday. I'll pick his brains, do what needs to be done and get back to ripping this thing apart. My biggest dread at this point is that there's simply nothing structurally sound to gusset the rear to, as it's all junk and coming out. Maybe i'll be getting worst case scenario later no matter what. We'll see.

Last edited:

Stev

Active Member

Still waiting on bodyshop guy. He's stood me up 4 times now. I like him, he does good work for cheap, but man is he the least reliable person I know.

I presume these door cards aren't repro'd anywhere huh? These are pretty hashed even without the lame 80's speakers punched through them. Looks like they used a chisel and foul language to do it.

I presume these door cards aren't repro'd anywhere huh? These are pretty hashed even without the lame 80's speakers punched through them. Looks like they used a chisel and foul language to do it.

'66 Fury I

Active Member

I found that careful use of a heat gun will easily remove the wrinkles in the vinyl around the arnrest bases. That hole is another matter...... LindsayStill waiting on bodyshop guy. He's stood me up 4 times now. I like him, he does good work for cheap, but man is he the least reliable person I know.

View attachment 639683

I presume these door cards aren't repro'd anywhere huh? These are pretty hashed even without the lame 80's speakers punched through them. Looks like they used a chisel and foul language to do it.

Stev

Active Member

I found that careful use of a heat gun will easily remove the wrinkles in the vinyl around the arnrest bases. That hole is another matter...... Lindsay

I'll give that a try. I do want a nice stereo in here so I think i'll just fill that with a speaker again. The hard part will be finding speakers that look period appropriate. It baffles me that no aftermarket audio equipment even vaguely attempts to look period correct.

Also I borked the remote mirror cable when removing it, it worked ok before but after i got the bezel loose it was dead. Cool.

Also bought all the ritzy junk from firm feel. Hopefully outside of local nickel and dime stuff this is the last money i'll be spending on this thing and hopefully none of this junk will ever need replacing ever again. I can't do another round for a while. Nobody ever made money doing this junk

On top of the eurethane bushings i'm gonna gusset the spring hangers and rear shackles too. I like luxury barges but that doesn't mean it has to be sloppy.

Last edited:

3175375

Old Man with a Hat

I looked for replacement door cards for Elwood, my 68 Fury II and nobody makes them too. I ended up replacing the fiber board by making a replacement out of two sandwiched pieces of 0.060” thick abs plastic (leftover from replacing the slideout floor in Bruno, our RV). I rebonded the vinyl to the abs plastic using 3M 090 spray adhesive.I'll give that a try. I do want a nice stereo in here so I think i'll just fill that with a speaker again. The hard part will be finding speakers that look period appropriate. It baffles me that no aftermarket audio equipment even vaguely attempts to look period correct.

Also I borked the remote mirror cable when removing it, it worked ok before but after i got the bezel loose it was dead. Cool.

View attachment 639714

Also bought all the ritzy junk from firm feel. Hopefully outside of local nickel and dime stuff this is the last money i'll be spending on this thing and hopefully none of this junk will ever need replacing ever again. I can't do another round for a while. Nobody ever made money doing this junk

On top of the eurethane bushings i'm gonna gusset the spring hangers and rear shackles too. I like luxury barges but that doesn't mean it has to be sloppy.

Stev

Active Member

Yeah that's what I thought. I Kind of want it exactly as grandpa had it anyway, so it being a little tore up is alright.

I can't tolerate non period looking speaker covers though. While it's on my mind, I'm gonna try to find something with a thick steel mesh and outer chrome ring, paint the mesh the dark metallic blue the other metal trim has and put a fratzog in the center.

Impulse bought these off Ebay. I know it's earlier smoother badge, but I think the rounder shape language suits the speaker better.

Why nobody makes any vintage looking speaker covers remains beyond me. Might have to make something from scratch.

Also I've given up on bodyshop buddy coming around. I'm just going to get back to it.

Though I did inspect where the tailgate strikers were adjusted to. The striker plates are currently adjusted fully forwards. Combine that with the fact that the tailgate hinges are mounted fully rearwards, to the point where the little roller panel that covers the gap falls off the tailgate, my current working theory is that the failing frame rails sagged and pushed the tailgate panel rearwards, and it is now settling back to where it ought to be.

Weirdly the left corner was also 1/2" lower than the right while the rockers were dead nuts level. I jacked it up and braced it, it seems happier now.

Iunno. Buddy might show up eventually, but it presently appears that after I weld everything back in, the car is actually going to end up more accurately located than when i started.

I can't tolerate non period looking speaker covers though. While it's on my mind, I'm gonna try to find something with a thick steel mesh and outer chrome ring, paint the mesh the dark metallic blue the other metal trim has and put a fratzog in the center.

Impulse bought these off Ebay. I know it's earlier smoother badge, but I think the rounder shape language suits the speaker better.

Why nobody makes any vintage looking speaker covers remains beyond me. Might have to make something from scratch.

Also I've given up on bodyshop buddy coming around. I'm just going to get back to it.

Though I did inspect where the tailgate strikers were adjusted to. The striker plates are currently adjusted fully forwards. Combine that with the fact that the tailgate hinges are mounted fully rearwards, to the point where the little roller panel that covers the gap falls off the tailgate, my current working theory is that the failing frame rails sagged and pushed the tailgate panel rearwards, and it is now settling back to where it ought to be.

Weirdly the left corner was also 1/2" lower than the right while the rockers were dead nuts level. I jacked it up and braced it, it seems happier now.

Iunno. Buddy might show up eventually, but it presently appears that after I weld everything back in, the car is actually going to end up more accurately located than when i started.

Last edited:

Stev

Active Member

So I was informed that apparently Porsche 356's have exactly the look I want for a speaker grille.

Swell. Just one problem.

Cool.

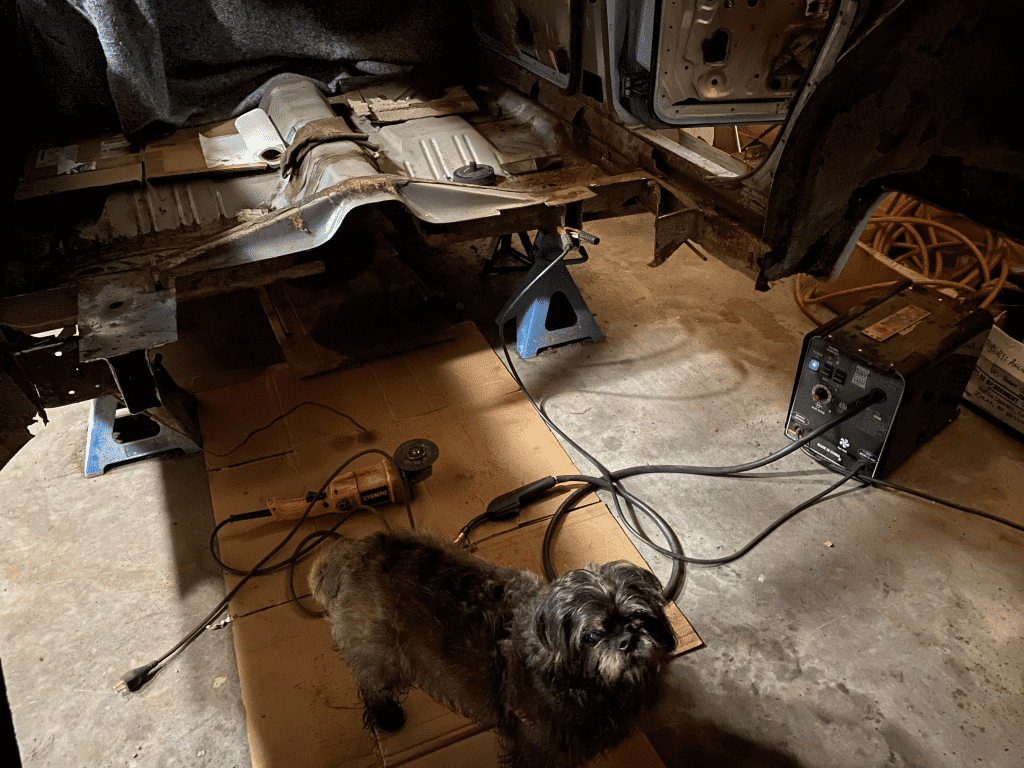

Wrangled the welder over and braced up the rockers. Laterally across to the trans hump and triangulated the right side to the back face of that lateral sheet metal kick up as well. I think that's more than enough to keep the rocker moving, going to start cutting out the inner quarter shortly.

Swell. Just one problem.

Cool.

Wrangled the welder over and braced up the rockers. Laterally across to the trans hump and triangulated the right side to the back face of that lateral sheet metal kick up as well. I think that's more than enough to keep the rocker moving, going to start cutting out the inner quarter shortly.

Last edited:

mopar preferred

Active Member

Have you checked Ebay for the grilles?

Stev

Active Member

Have you checked Ebay for the grilles?

Yeah the only ones on ebay for the Porsche grilles are either insanely expensive originals or the same repros. I thought E type covers would work but they're slightly smaller and don't appear to be repro'd. Everything else on there is just plastic tat.

Probably just going to end up making what I want from scratch. I've got bigger stuff to do for now. Just baffling there's literally no tasteful audio equipment made anywhere.

Stev

Active Member

You know I wonder if any part of the original car will be left after this. Now I know why there was 1/4" of bondo on this whole corner.

Similar threads

- Replies

- 11

- Views

- 554

- Replies

- 5

- Views

- 725

- Replies

- 13

- Views

- 2K