Gerald Morris

Senior Member

Having planned THIS move for several years anyway, my hopes that a new pusher fan would suffice to keep Gertrude running cool inspired me to go ahead, replace the cheap NAPA alternator with the squirrely bearings, upgrade the wiring, and pop a new pusher fan on the front of the undersized radiator for good measure. Those of you who fret about bypassing ammeters now have another method, the "Morris Bypass" to consider too.

First, the new PowerMaster 17019 95A alternator!

Pretty thing, ain't it? Note the 2 wires currently on the charging stud. This temporary arrangement is Phase 1 of the Morris Bypass. I ran a #8 AWG welding wire directly to the + post on the battery around the front of the radiator yoke in the 3/8 inch split loom. BUT, since I hadn't time enough just yet to clear out the rubbishy #12AWG charging wire from the dash, I had to protect it as best I may with some more fusible link wire. I hated using it fo9r this, but the stuff melts quicker than straight copper. I also still have the #10AWG battery lead from the starter relay, which is protected by a #14 AWG fusible link from Ma Par, at the bulkhead connector. This, like that ridiculous 12 gauge charging lead, is due for elimination this coming week, and both will be replaced by a nice 8 gauge welding wire running straight into the dash, where it will be lugged to the now lugged together charging lead and battery lead that were on the ammeter, which has been completely disconnected. I normally place all my fusible links right by the battery, which makes it easy to see them and replace them if needed.

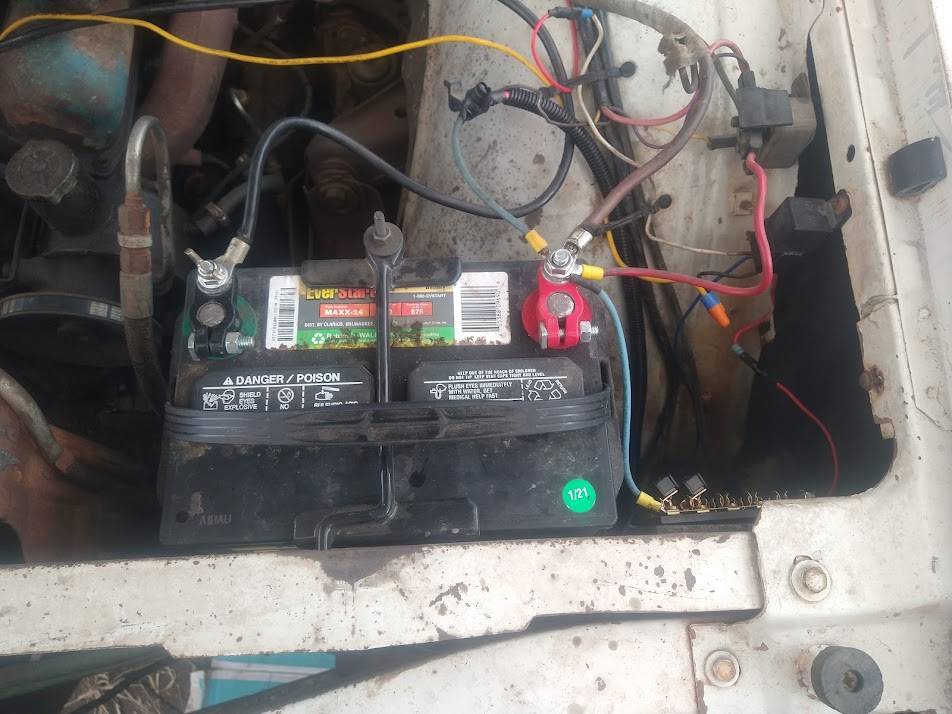

Note the 2 fusible links now attached via ring terminals to the marine battery terminal. Both measured just 6 inches long before stripping and terminating. The new fuseblock, visible on the lower right, has a nice plastic lid to place over it, protecting that brass bus and the circuits from random conductors falling on them. I installed a pair of 30A breakers on the left for the headlight circuits, TBA.

Note the 2 fusible links now attached via ring terminals to the marine battery terminal. Both measured just 6 inches long before stripping and terminating. The new fuseblock, visible on the lower right, has a nice plastic lid to place over it, protecting that brass bus and the circuits from random conductors falling on them. I installed a pair of 30A breakers on the left for the headlight circuits, TBA.

The new pusher is fed from the 30A fused circuit on the far right. Note the yellow lead running from the

water pump to the fan relay. I use a 200F thermostatic switch, 1/8 inch NPT. This works well. I'll put a toggle switch on this switched ground soon too.

water pump to the fan relay. I use a 200F thermostatic switch, 1/8 inch NPT. This works well. I'll put a toggle switch on this switched ground soon too.

First, the new PowerMaster 17019 95A alternator!

Pretty thing, ain't it? Note the 2 wires currently on the charging stud. This temporary arrangement is Phase 1 of the Morris Bypass. I ran a #8 AWG welding wire directly to the + post on the battery around the front of the radiator yoke in the 3/8 inch split loom. BUT, since I hadn't time enough just yet to clear out the rubbishy #12AWG charging wire from the dash, I had to protect it as best I may with some more fusible link wire. I hated using it fo9r this, but the stuff melts quicker than straight copper. I also still have the #10AWG battery lead from the starter relay, which is protected by a #14 AWG fusible link from Ma Par, at the bulkhead connector. This, like that ridiculous 12 gauge charging lead, is due for elimination this coming week, and both will be replaced by a nice 8 gauge welding wire running straight into the dash, where it will be lugged to the now lugged together charging lead and battery lead that were on the ammeter, which has been completely disconnected. I normally place all my fusible links right by the battery, which makes it easy to see them and replace them if needed.

The new pusher is fed from the 30A fused circuit on the far right. Note the yellow lead running from the