I will be getting my repaired and cleaned radiator back this afternoon. I have been gathering parts to put the cooling system back together. I am installing a Hayden 687 plate type trans cooler to take a little load off the rad. I also want to add a fan clutch. The parts manuals list the pulley and spacer as being identical. I already have the 7 blade A/C fan on the car. I got an ACDelco 15-80250 clutch. There seem to be problems with the Hayden HD clutch and the ACDelco unit comes highly recommended. The FSM has no specifics or pics on this install.....has anyone done this sort of thing?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Putting Fan Clutch on a Non A/C Car?

- Thread starter Mr onetwo

- Start date

commando1

Old Man with a Hat

I'd like to sidestep the clutch issue for one brief moment and plead with you to not install the auxiliary cooler with those F#$@-ING zip ties and use honest to god brackets and fasteners.

Thank you.

P.S. It would kill me if I had to resort to rubber hose instead of hard plumbing but that's the traditional me talking.

Thank you.

P.S. It would kill me if I had to resort to rubber hose instead of hard plumbing but that's the traditional me talking.

twostick

Senior Member

You will have to find a fan clutch specific fan. The fan bolts to the aluminum part of the clutch so it needs a BIG hole in the middle for the shaft to go thru.

I got mine from a salvage yard but the days of finding 40+ year old cars in yards has passed for most of us.

If you don't have a "vintage" yard near by, I would return that clutch (or keep it for a spare) and order a complete kit from Mancini. It includes the fan and the clutch.

If the car doesn't already have one, a fan shroud would be a good addition at this time too.

http://www.manciniracing.com/vifanpa1.html

Kevin

I got mine from a salvage yard but the days of finding 40+ year old cars in yards has passed for most of us.

If you don't have a "vintage" yard near by, I would return that clutch (or keep it for a spare) and order a complete kit from Mancini. It includes the fan and the clutch.

If the car doesn't already have one, a fan shroud would be a good addition at this time too.

http://www.manciniracing.com/vifanpa1.html

Kevin

1966newport

Well-Known Member

- Joined

- Jan 20, 2012

- Messages

- 909

- Reaction score

- 226

geeze, summit sells clutch fans in many sizes

Thanks Kevin, those kits are on backorder at Mancini and I think I will be able to find a used cheap stock one somewhere. I think 22" fan shrouds are really hard to find.You will have to find a fan clutch specific fan. The fan bolts to the aluminum part of the clutch so it needs a BIG hole in the middle for the shaft to go thru.

I got mine from a salvage yard but the days of finding 40+ year old cars in yards has passed for most of us.

If you don't have a "vintage" yard near by, I would return that clutch (or keep it for a spare) and order a complete kit from Mancini. It includes the fan and the clutch.

If the car doesn't already have one, a fan shroud would be a good addition at this time too.

http://www.manciniracing.com/vifanpa1.html

Kevin

Don't worry, it will be done to my high standards. I may bend up 3/8" steel lines myself. The cooler is furnished with -6 AN fittings(JIC) instead of hose barbs. I will hang the cooler on steel angles.I'd like to sidestep the clutch issue for one brief moment and plead with you to not install the auxiliary cooler with those F#$@-ING zip ties and use honest to god brackets and fasteners.

Thank you.

P.S. It would kill me if I had to resort to rubber hose instead of hard plumbing but that's the traditional me talking.

I just ran into a problem....the fan clutch I ordered is too tall. There is not enough space between the pulley and the radiator for it to fit. Evidently the max cooling radiator must be thinner than the 22" std. rad. The clutch from a '64 Newport with a 361 engine is identical except it is 1/2" shorter. It will have to work....there isn't any other one I can find in the application manual that is shorter.

twostick

Senior Member

The one I put on my 66 came off some random c-body in a yard. IIRC it was a 69 300 but I'm not sure.

After I installed it, it was apparent the hub was FUBAR so I just ordered one for a C-body and bolted it up.

I would have to go and look but I'm pretty sure the hub bolts direct to the pump. No spacers.

Kevin

After I installed it, it was apparent the hub was FUBAR so I just ordered one for a C-body and bolted it up.

I would have to go and look but I'm pretty sure the hub bolts direct to the pump. No spacers.

Kevin

Well, I lucked out and found a fan from my friend Chuck down in Lewiston for $20.Gives me a chance to check out a secret salvage yard that supposedly has 50+ C-bodies in it....we'll see about that. In the meantime the correct clutch is arriving tomorrow(gottah love Amazon Prime).I ordered 2 lengths of 3/8" annealed steel tubing from Inline Tube and should have that by the end of the week.....fingers crossed. I also found these fittings which you guys may find useful....they screw into the 727 and go straight to -6AN. http://www.ebay.com/itm/6-AN-To-1-8...Torqueflite-/231282930429?hash=item35d98972fd

twostick

Senior Member

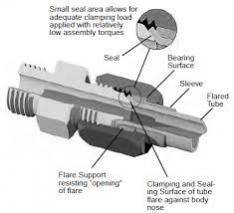

727 case takes an 1/8 NPT fitting AFAIK. That fitting you show with the washer isn't pipe thread. That style of fitting however will work if you want to convert your brake flex lines to AN fittings and use braided stainless flex lines. That style fitting will screw directly into a brake caliper. They sell another adapter that goes from tube to NPT for the end that goes to the hard line.

Kevin

Kevin

commando1

Old Man with a Hat

I was just about to say that but you beat me to it.727 case takes an 1/8 NPT fitting AFAIK. That fitting you show with the washer isn't pipe thread. That style of fitting however will work if you want to convert your brake flex lines to AN fittings and use braided stainless flex lines. That style fitting will screw directly into a brake caliper. They sell another adapter that goes from tube to NPT for the end that goes to the hard line.

Kevin

This is the correct fitting except that it may not clear the tranny case so you will need a nipple to extend it out further too.

1/8 NPT MALE to -6AN

Or, as two stick said use a 3/8-24 FEMALE to 1/8 MALE adaptor for the fittings you bought.

You guys are missing the point of these fittings. They are straight thread with a copper sealing washer to take the stress off the 727 case. They can crack at those ports if an NPT fitting is over tightened.Also, he made them with a larger ID so you get more flow. I am not using AN style fittings...they are too bulky. I will be using -6 JIC tube nuts and sleeves. Both AN and JIC are 37 degree flare.

twostick

Senior Member

How do you propose to screw the straight thread into the pipe thread in the case?

Kevin

Kevin

commando1

Old Man with a Hat

Ok. I have to bow out. I'm approaching it differently then. Carry on

The straight and taper thread are the same.....it is made to screw right in by hand. A soft material like aluminum is not great for tapered NPT pipe thread.How do you propose to screw the straight thread into the pipe thread in the case?

Kevin

twostick

Senior Member

If your are going to use tubing, I don't see the advantage over the OEM compression fittings. The only practical reason to go with an AN fitting is so you can use hose.

Cracking the case IMHO is a non issue. I've seen lots of fittings broken off in cases, never seen a case cracked by one. Relying on a gasket to seal on a non spot faced surface might be asking for a leak.

Kevin

Cracking the case IMHO is a non issue. I've seen lots of fittings broken off in cases, never seen a case cracked by one. Relying on a gasket to seal on a non spot faced surface might be asking for a leak.

Kevin

commando1

Old Man with a Hat

:tard:The straight and taper thread are the same.....it is made to screw right in by hand.

That needs further elaboration so I can understand that.

twostick

Senior Member

:tard:

That needs further elaboration so I can understand that.

Me too.

I looked up the 2 threads and it is the same 1/8 27 but they call for different tap drill sizes so one may thread into the other but I suspect the thread engagement will be FUBAR. FUBAR and hydraulic pressure not a good combination IMHO.

Kevin

68plymouth383

Senior Member

Sometimes reinventing the wheel isn't a good thing....

commando1

Old Man with a Hat

I have to say that I agree with you.Sometimes reinventing the wheel isn't a good thing....

I bought the correct OEM type cooler line to transmission fittings on ebay for 5 bucks ea. recently. After all, how many gabillion of these have been installed with no problems.

Similar threads

- Locked

- Replies

- 0

- Views

- 1K