3175375

Old Man with a Hat

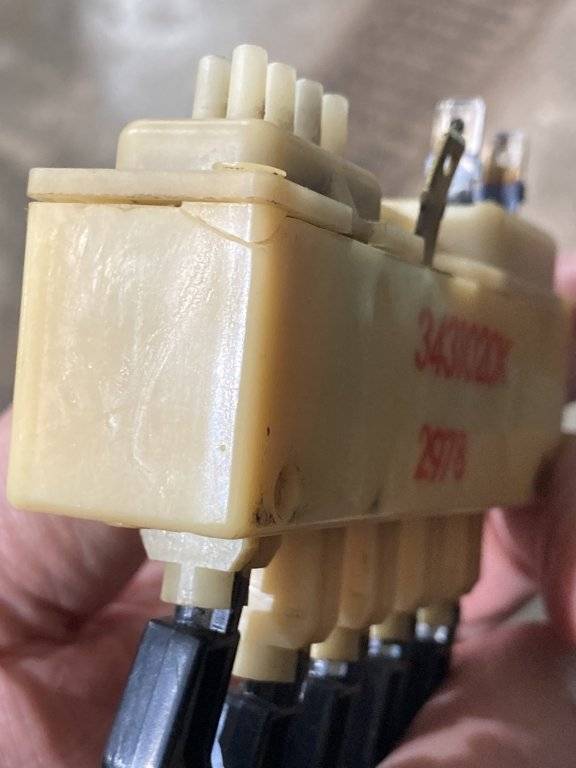

Taking a stab at rebuilding the control switch for the ac/heater.

Got it all apart and am going to reassemble today.

I used the Bob Smith Industries Super Glue with accelerator and JB Weld to shore up the corners. Also used the reference in another post here (linking to an A body thread) to drill the rivets and tap the holes for 4-40 threaded pan head screws.

Vacuum ports look good.

Got it all apart and am going to reassemble today.

I used the Bob Smith Industries Super Glue with accelerator and JB Weld to shore up the corners. Also used the reference in another post here (linking to an A body thread) to drill the rivets and tap the holes for 4-40 threaded pan head screws.

Vacuum ports look good.