3175375

Old Man with a Hat

I am going to have to chase out the switched vacuum hoses. On initial peek at the lines, I see the extension hose bundle, and shortly after that, I see one of the 3 tees.

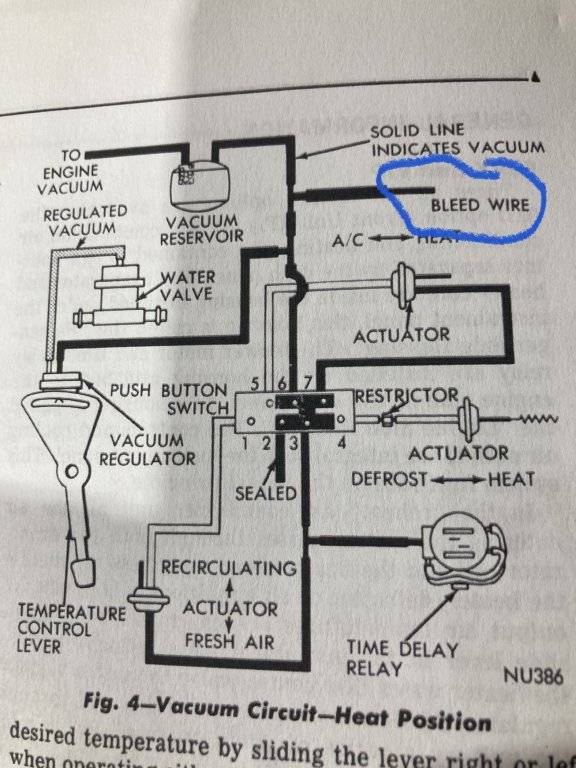

I don’t see the bleed wire (really a hose).

Does anyone have any reference material on how and where the tees are routed/located?

I have a feeling that some things are missing…

I don’t see the bleed wire (really a hose).

Does anyone have any reference material on how and where the tees are routed/located?

I have a feeling that some things are missing…